Sewage treatment method of casing plant

A sewage treatment method and technology of sewage treatment station, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Efficiency, the effect of reducing the processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

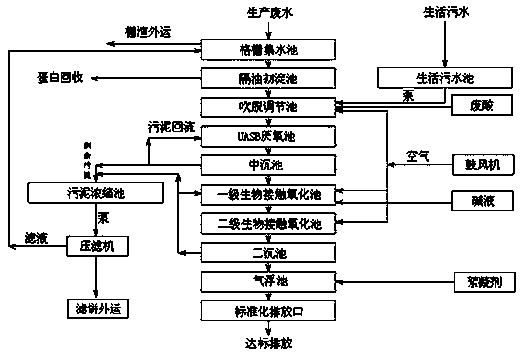

[0034] like figure 1 Shown, a kind of casing factory sewage treatment method comprises the following steps:

[0035] (1) Salt casing production wastewater enters the collection pipe network and is collected to the grid set of the sewage treatment station. The large suspended solid matter in the sewage is intercepted by the grid set, and the separated grid residue is transported out for treatment, and the separated wastewater is processed in the next step ;

[0036] (2) Pump the wastewater from the previous step into the oil-separating sedimentation tank, let it stand still, and the insoluble protein precipitates at the bottom of the tank. After removing the surface layer of animal fat, the wastewater is processed in the next step, and the insoluble protein deposited at the bottom of the tank is Sexual proteins are recycled;

[0037] (3) Flow the oil- and protein-removed waste water from the pipeline into the blow-off regulating tank, and test the pH value of the waste water....

specific Embodiment 2

[0045] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the stirring speed in step (7) is 500rpm, the temperature in the pool is controlled at 40°C, the hydraulic retention time is 40h, and the anaerobic bacteria load is 20g / L; In step (8), the temperature in the first-level biological contact oxidation tank is controlled at 35°C, the hydraulic retention time is 12h, and the load of aerobic bacteria is 15g / L; the temperature in the second-level biological contact oxidation tank is controlled at 35°C, and the hydraulic retention time is 8h. The load of aerobic bacteria is 10g / L.

specific Embodiment 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the stirring speed in step (7) is 400rpm, the temperature in the pool is controlled at 35°C, the hydraulic retention time is 35h, and the anaerobic bacteria load is 15g / L; The temperature in the first-grade biological contact oxidation tank is controlled at 30°C, the hydraulic retention time is 10 hours, and the load of aerobic bacteria is 12.5g / L. It is 8.5g / L; in step (9), polyaluminum chloride is used as the flocculant, which can treat wastewater due to the bridging effect of its hydroxide ions and the polymerization of polyvalent anions. of suspended matter.

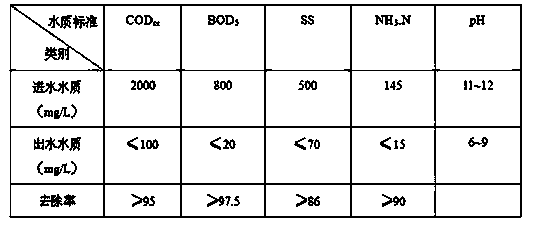

[0047] Adopt processing method of the present invention to have following effect:

[0048] 1) The grease trap is used in the front section to remove animal fat, and the air flotation equipment is used in the back section to further remove animal grease and suspended solids to ensure that all indicators in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com