Reduction ironmaking process of bottom heating type fixed furnace hearth

A hearth and process technology, which is applied in the field of bottom heating fixed hearth reduction ironmaking process, can solve the problems of electrode consumption, difficult direct reduction of iron, sponge iron gangue and high sulfur content, so as to prevent secondary oxidation and reduce production costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

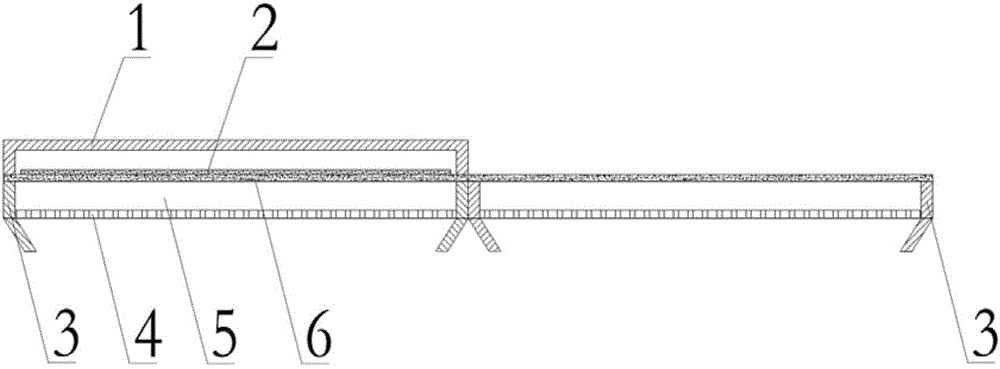

Image

Examples

Embodiment 1

[0033] Raw material preparation: Mix the fine iron powder and make pellets on the pelletizer, the diameter of the pellets is 20mm. The lump coal is crushed into small pieces of coal about 24mm in diameter.

[0034] Cloth: Use a trolley or a cloth belt table to cloth, firstly distribute the lump coal evenly on the hearth, and then distribute the balls on the lump coal;

[0035] Reduction area setting: hearth setting is 6m×6m. The number of hearths can be set according to the annual production requirements;

[0036] Combustion area setting: coal is used as fuel, the fuel is put into the furnace through the furnace door, ignited and burned, and a grate is provided at the lower part of the furnace to facilitate ash discharge;

[0037] Raw material reduction: In the later stage of furnace charge reduction, the furnace temperature is controlled at 1100-1300°C, and the optimal temperature is 1200°C;

[0038] Discharge: use scraper discharge. The metallization rate of the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com