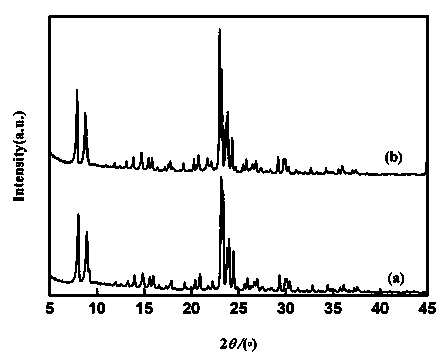

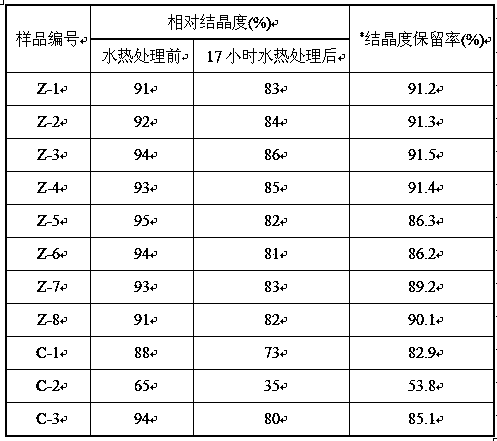

Method for synthesizing small crystal grain P-ZSM-5 molecular sieve by using low cost raw material

A technology of P-ZSM-5 and ZSM-5, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems that industrialization cannot be truly realized, and achieve the improvement of hydrothermal Stability, increased propylene yield, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Measure 0.72ml of concentrated sulfuric acid and dissolve it in 34.4ml of deionized water with stirring at room temperature, weigh 0.68g of aluminum sulfate, 3.09g of sodium chloride, and 0.165g of isopropanol, and add them to the above mixture in turn and stir for 30 minutes. Measure 0.608 The amount of substance in ml is 1 mol / L diammonium hydrogen phosphate solution, which is slowly added to the above solution and stirred for 1 h, marked as A.

[0030] Weigh 16.7g of water glass and 0.2g of seed crystals and dissolve them completely in 13.7ml of water, stir vigorously to mix the two substances evenly, slowly add 1.74ml of n-butylamine to the above mixture under stirring conditions, stir for 30min, and mark as b. Slowly add solution B to solution A, then stir on a magnetic stirrer for 2 hours, stir and age in a 70oC water bath for 6 hours, then raise the temperature to 180oC to crystallize for 30 hours, immediately cool the reactor to room temperature with tap water a...

Embodiment 2

[0032]Measure 0.36ml of concentrated sulfuric acid and dissolve it in 19.2ml of deionized water with stirring at room temperature, respectively weigh 0.68g of aluminum sulfate, 4.5g of sodium chloride, and 0.1g of isopropanol into the above mixture and stir for 30 minutes, then measure 1.216ml of ammonium dihydrogen phosphate solution with a concentration of 0.4mol / L was slowly added to the above solution and stirred for 1h, marked as A.

[0033] Weigh 10.7g of water glass and 0.4g of seed crystals and dissolve them completely in 25.6ml of water, stir vigorously to mix the two substances evenly, slowly add 2.5ml of n-butylamine dropwise to the above mixture under stirring conditions, stir for 30min, and mark for B. Slowly add solution B to solution A, then stir on a magnetic stirrer for 2 hours, stir and age in a 60oC water bath for 8 hours, then raise the temperature to 180oC for crystallization for 24 hours, immediately cool the reactor to room temperature with tap water aft...

Embodiment 3

[0035] Measure 1.08ml of concentrated sulfuric acid and dissolve it in 24.4ml of deionized water with stirring at room temperature, weigh 0.5g of aluminum sulfate, 3.09g of sodium chloride, and 0.165g of isopropanol, and add them to the above mixture in turn and stir for 30 minutes, then measure 0.608ml of diammonium hydrogen phosphate and ammonium dihydrogen phosphate solution with a substance concentration of 0.6mol / L was slowly added to the above solution and stirred for 2 hours, marked as A.

[0036] Weigh 13g of water glass and 0.2g of seed crystals and completely dissolve them in 10.3ml of water, stir vigorously to mix the two substances evenly, slowly add 1.25ml of n-Damine to the above mixture under stirring conditions, stir for 30min, and mark it as B . Slowly add solution B to solution A, then stir on a magnetic stirrer for 2 hours, stir and age in a 70oC water bath for 12 hours, then crystallize in an oven at 170oC for 36 hours, immediately cool the reactor to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com