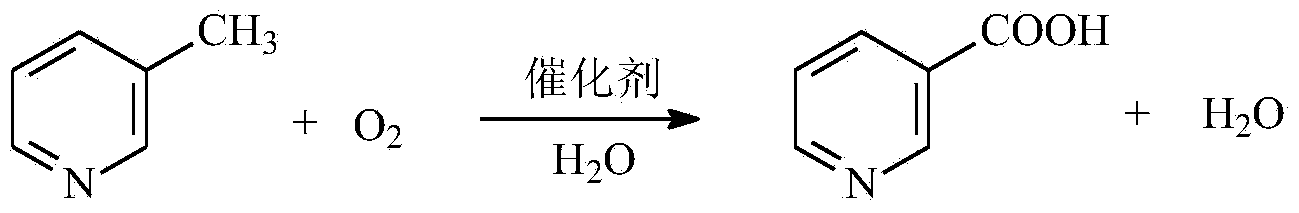

Process and device for one-step air catalytic oxidation synthesis of picolinic acid type compounds

A technology for synthesizing picolinic acid and catalytic oxidation, applied in organic chemistry and other directions, can solve the problems of large pollutant discharge, low working efficiency of electrolyzer, consumption of caustic soda, etc., to reduce energy consumption, pollutant discharge, and raw material conversion rate. The effect of high product purity and avoidance of the use of oxidizing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

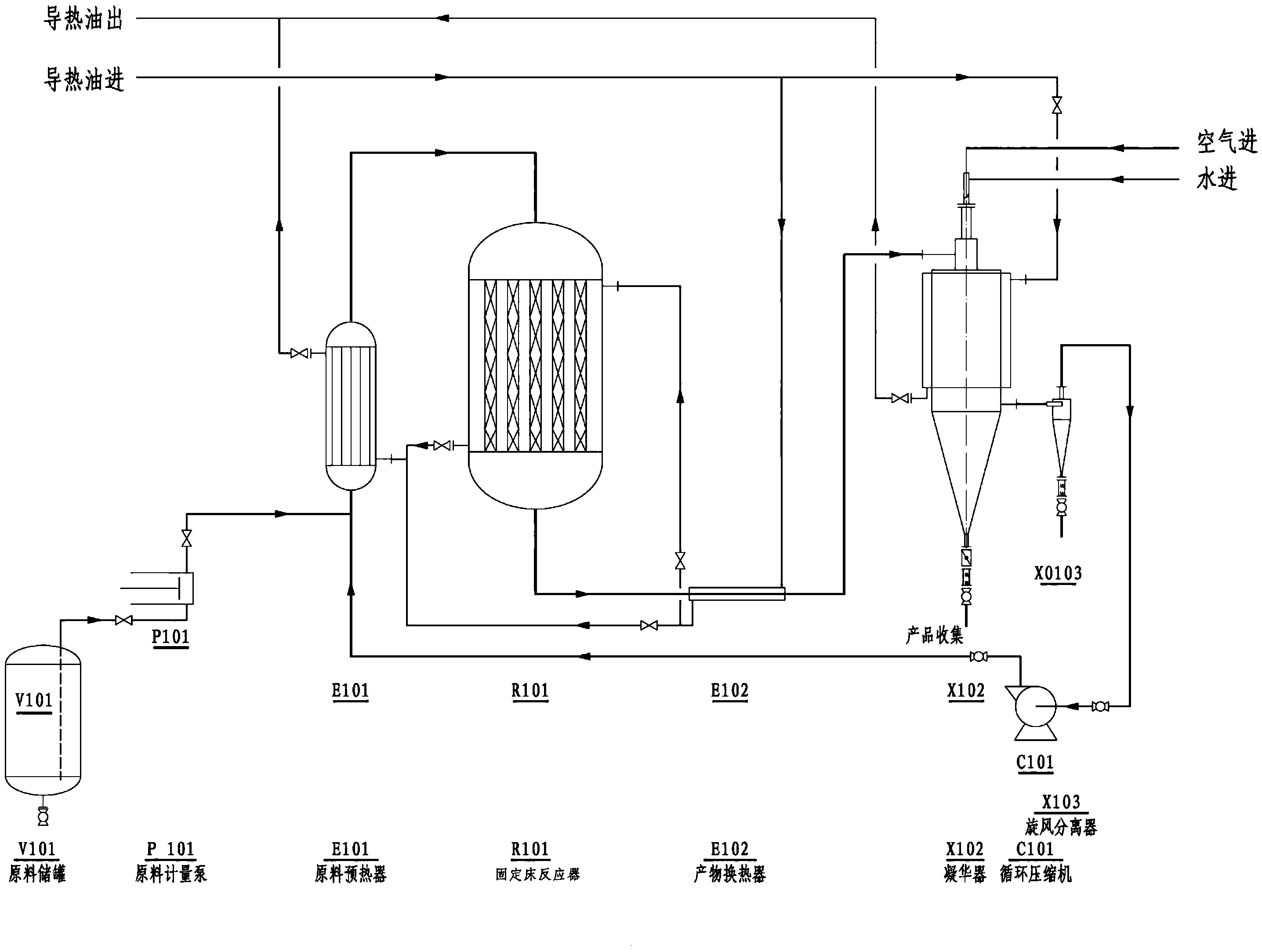

[0036] Such as figure 1 As shown, the device of the present invention includes raw material storage tank V101, raw material preheater E101, fixed bed reactor R101, desublimator X102, cyclone separator X103, circulating compressor C101, product heat exchanger E102; raw material storage tank V101 The raw material metering pump P101 is connected to the bottom inlet of the raw material preheater E101, and the top outlet of the raw material preheater E101 is connected to the top raw material gas inlet of the fixed bed reactor R101, and the fixed bed reactor R101 is filled with V 2 o 5 / TiO 2 Catalyst, the bottom of the fixed bed reactor R101 is provided with a reaction gas outlet, the reaction gas outlet is connected to the inlet of the product heat exchanger E102, the outlet of the product heat exchanger E102 is connected to the reaction gas inlet at the upper end of the desublimer X102, and the bottom of the desublimer X102 There is a first collection product outlet, an air inl...

Embodiment 2

[0053] Reaction apparatus and flow process are the same as embodiment 1, and difference is, and reaction raw material is 2-picoline, and raw material 2-picoline, water vapor and air are fed by material amount ratio 1: 50: 60, 2-methylpyridine The mass space velocity of base pyridine feed is 0.02h -1 , the follow-up steps are the same as in Example 1, and the results show that the one-way conversion rate of 2-picoline is 88%, the selectivity to product 2-pyridinecarboxylic acid is 94%, and the one-way molar yield of 2-picolinic acid is 83%. Purity up to 99.5%, CO 2 The selectivity can be controlled at ≤3.0%.

Embodiment 3

[0055] Reaction apparatus and flow process are the same as embodiment 1, and difference is, and reaction raw material is 4-picoline, and raw material 4-picoline, water vapor and air are fed by material amount ratio 1: 70: 100, 4-methylpyridine The mass space velocity of base pyridine feed is 0.5h -1 , the follow-up steps are the same as in Example 1, and the results show that the single-pass conversion rate of 4-picoline is 85%, the selectivity to the product isonicotinic acid is 91%, the single-pass molar yield of isonicotinic acid is 77%, and the purity of isonicotinic acid reaches 99.5%. % for CO 2 The selectivity can be controlled at ≤3.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com