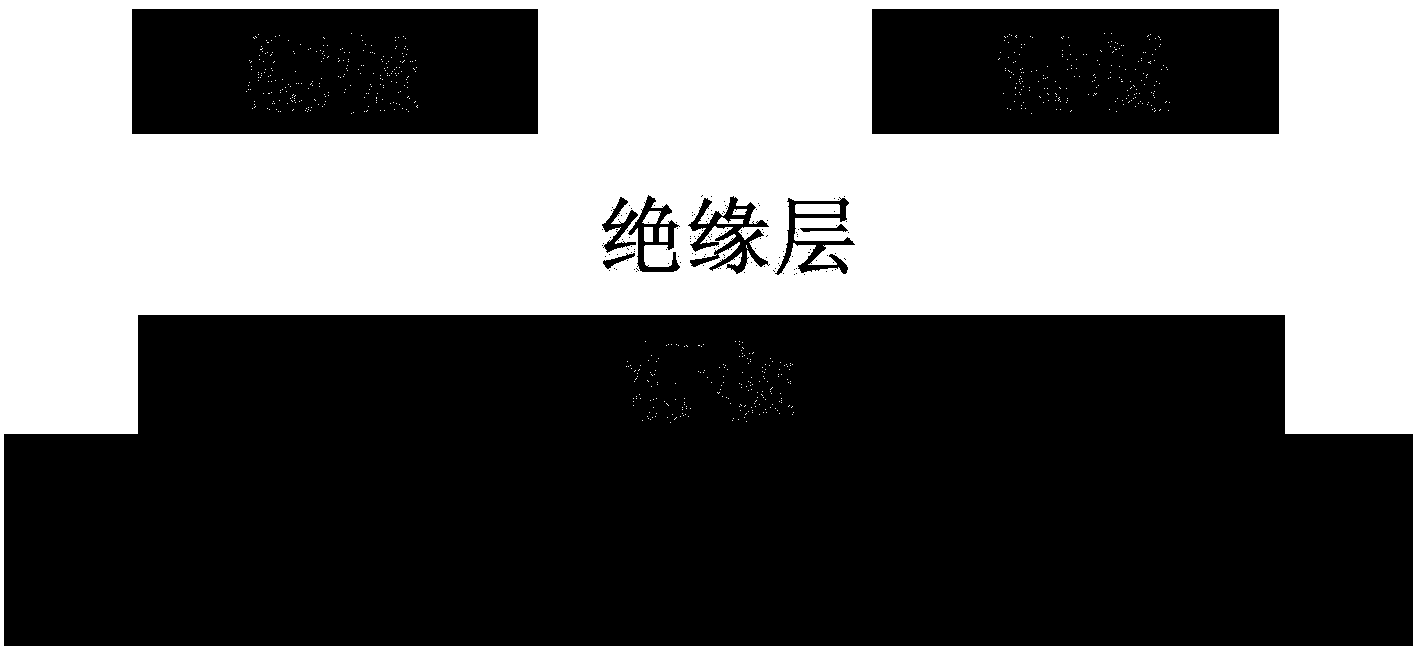

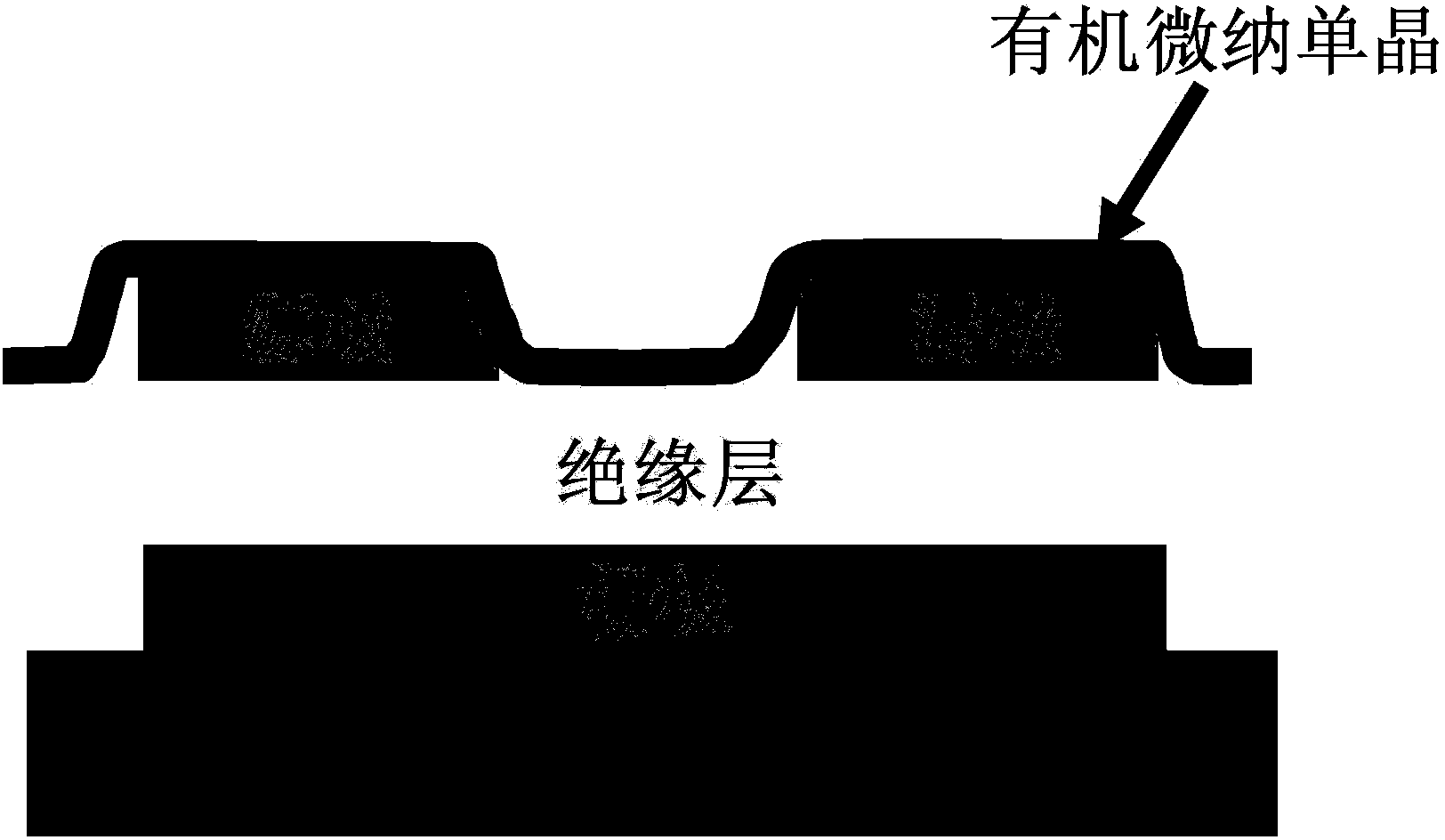

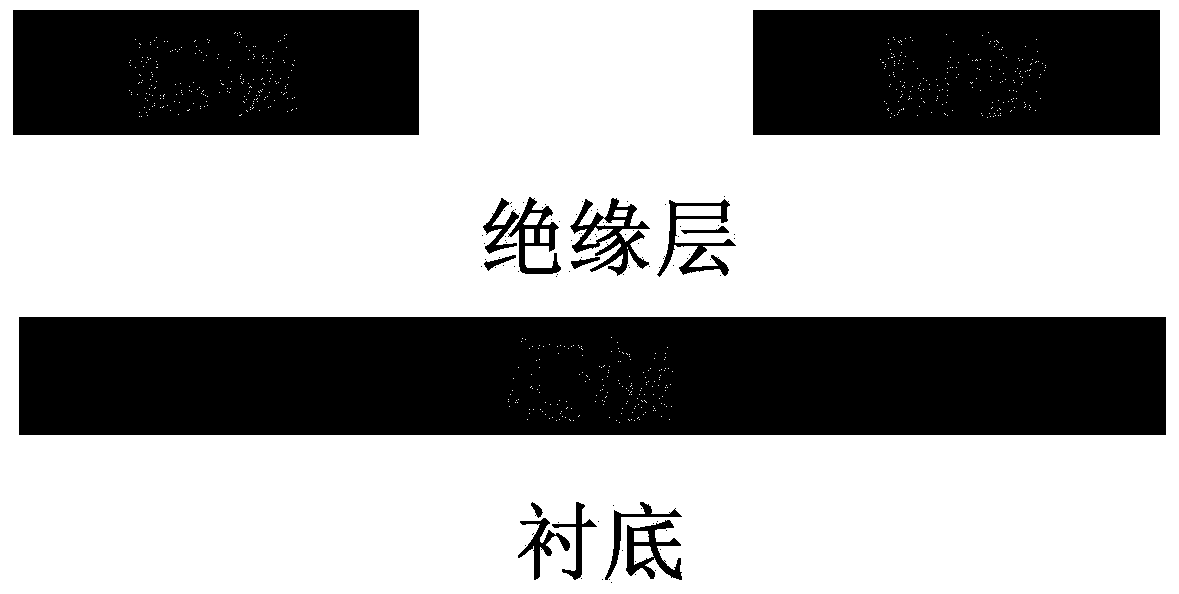

Organic monocrystal field effect circuit and preparation method thereof

A field effect and circuit technology, which is applied in the field of organic single crystal field effect circuits and its preparation, can solve the problems of device performance degradation, easy to generate defects, and limit the size of crystals, and achieve high integration and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1. Preparation of Copper Phthalocyanine Organic Single Crystal Field Effect Circuit

[0050] 1. Preparation of circuit mask

[0051] (1) Use L-editor software to design the circuit mask pattern of source electrode, drain electrode, gate electrode and external electrode respectively; each layer should design the same alignment pattern, so as to align various electrode layers next.

[0052] (2) The circuit mask used in this embodiment was purchased from Nanjing Qingwei Electronics Technology Co., Ltd. The specific process is: spin-coat polymethyl methacrylate on quartz, and use laser direct writing method to etch step 1) to obtain The pattern of the circuit mask plate; then evaporate chromium (100nm), and remove the polymethyl methacrylate to obtain the circuit mask plate of the source electrode, the drain electrode, the gate and the external electrode.

[0053] 2. Preparation of flexible planar embedded laminated electrodes with inverter patterns

[0054] (1) U...

Embodiment 2

[0071] Example 2, preparation of rubrene organic single crystal field effect circuit (the aspect ratio of the driver device and load device of the designed rubrene single crystal field effect inverter is 1 / 5)

[0072] 1. Preparation of circuit mask

[0073] (1) Use L-editor software to design the circuit mask pattern of source electrode, drain electrode, gate electrode and external electrode respectively; each layer should design the same alignment pattern, so as to align various electrode layers next.

[0074] (2) The circuit mask plate used in this embodiment was purchased from Nanjing Qingwei Electronics Technology Co., Ltd. The specific process is: spin-coat polymethyl methacrylate on the glass, and use the laser direct writing method to etch step 1) to obtain The pattern of the circuit mask plate; then evaporate chromium, and remove the polymethyl methacrylate to obtain the circuit mask plate of the source electrode, the drain electrode, the gate electrode and the externa...

Embodiment 3

[0091] Example 3, preparation of rubrene organic single crystal field effect circuit (the aspect ratio of the driver device and load device of the designed rubrene single crystal field effect inverter is 2 / 5)

[0092] 1. Preparation of circuit mask

[0093] (1) Use L-editor software to design the circuit mask pattern of source electrode, drain electrode, gate electrode and external electrode respectively; each layer should design the same alignment pattern, so as to align various electrode layers next.

[0094] (2) The circuit mask used in this embodiment was purchased from Nanjing Qingwei Electronics Technology Co., Ltd. The specific process is: spin-coat polymethyl methacrylate on quartz, and use laser direct writing method to etch step 1) to obtain The pattern of the circuit mask plate; then evaporate chromium, and remove the polymethyl methacrylate to obtain the circuit mask plate of the source electrode, the drain electrode, the gate electrode and the external electrode. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com