Alkaline earth-rare earth ternary sulfide luminescent material and preparation method thereof

A ternary sulfide, luminescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of short emission peak wavelength, and achieve the effect of improving luminous efficiency, high quality and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

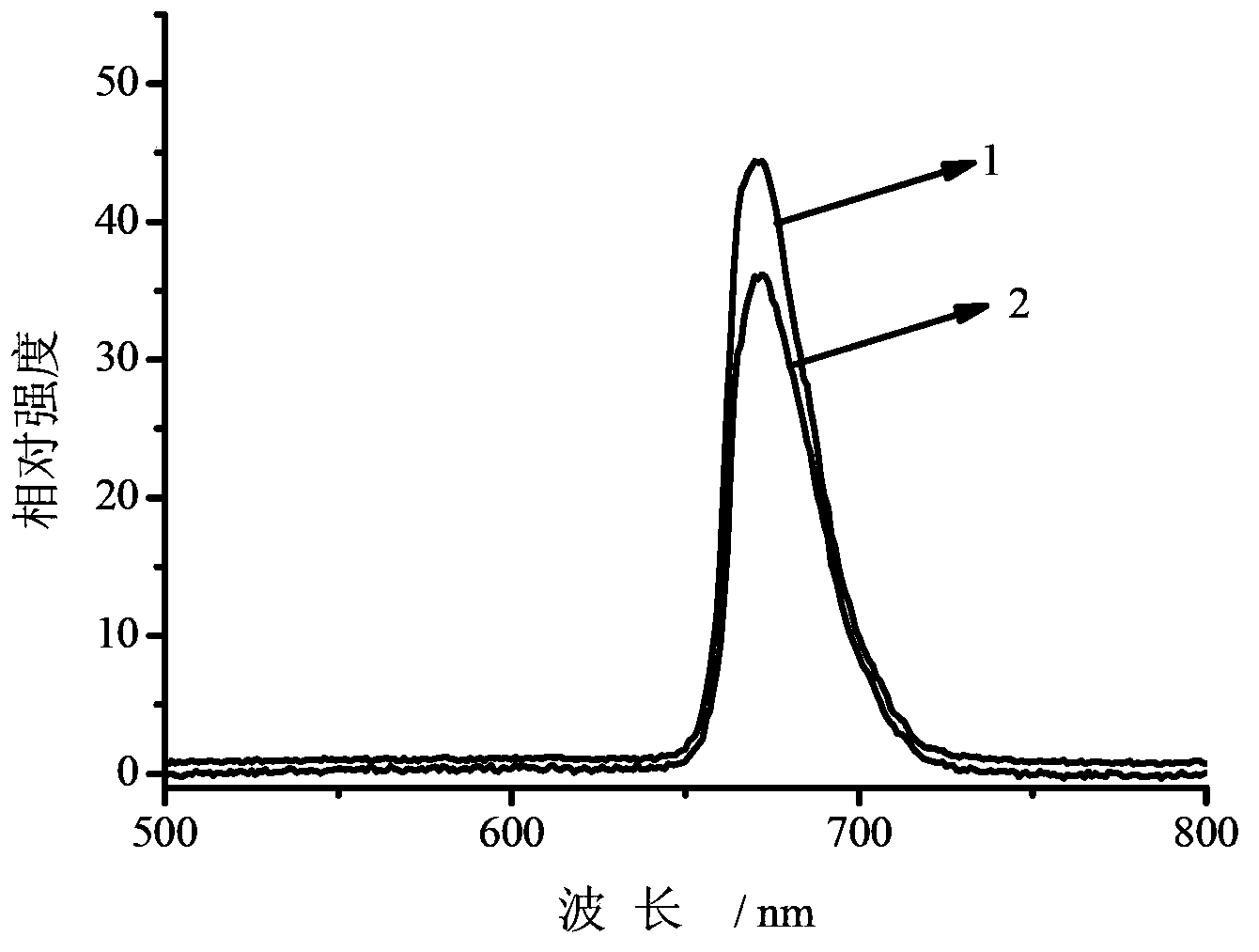

Image

Examples

Embodiment 1

[0023] Example 1: SrY 1.99 S 4 :Er 0.01 3+ ,Pd 1×10ˉ5 :

[0024] Preparation of Pd nanoparticle sol: Weigh 0.176mg palladium chloride (PdCl 2 2H 2 O) Dissolved in 10mL of deionized water; when the palladium chloride was completely dissolved, weigh 11.0mg of sodium citrate and 4.0mg of sodium lauryl sulfate, and dissolve them in an aqueous solution of palladium chloride under a magnetic stirring environment; Weigh 0.38mg sodium borohydride and dissolve in 100mL deionized water to obtain a concentration of 1×10 -4 mol / L sodium borohydride solution; under the condition of magnetic stirring, quickly add 10mL of the above-mentioned sodium borohydride solution to the above-mentioned palladium chloride solution, react for 20min, and obtain 20mL Pd content of 4×10 -5 mol / L Pd nanoparticle sol;

[0025] Weigh 0.8226g Sr(CH 3 COO) 2 , 2.1772g Y(CH 3 COO) 3 and 0.0138g Er(CH 3 COO) 3Put it in a container, then add 50mL of a mixed solution of ethanol and water with a volume ...

Embodiment 2

[0027] Example 2: BaY 1.5 S 4 :Er 0.5 3+ ,Au 1×10ˉ2

[0028] Preparation of Au-containing nanoparticle sol: Weigh 48.4 mg of chloroauric acid (AuCl 3 ·HCl·4H 2 O) be dissolved in the deionized water of 10mL; Under the condition of magnetic stirring, 14mg sodium citrate and 6mg cetyltrimethylammonium bromide are dissolved in the above-mentioned chloroauric acid solution; Weigh 1.9mg sodium borohydride Dissolve in 10 mL of deionized water to obtain a concentration of 5 × 10 -3 mol / L sodium borohydride solution; weigh 17.6mg of ascorbic acid and dissolve it in 10mL of deionized water to obtain a concentration of 1×10 -2 mol / L ascorbic acid solution; under the condition of magnetic stirring, first add 5mL of the above-mentioned sodium borohydride solution to the above-mentioned chloroauric acid solution, after reacting for 5min, then add 5mL of the above-mentioned ascorbic acid solution to the above-mentioned chloroauric acid solution, and continue the reaction 20min, the ...

Embodiment 3

[0031] Example 3: SrY 1.7 S 4 :Er 0.3 3+ ,Pt 5×10ˉ3 :

[0032] Containing the preparation of Pt nanoparticle sol: take by weighing 25.9mg chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) be dissolved in 17mL of deionized water; under the condition of magnetic stirring, 400mg sodium citrate and 600mg sodium dodecylsulfonate are dissolved in the above-mentioned chloroplatinic acid solution; 1.9mg sodium borohydride is weighed and dissolved in 10mL deionized water to obtain a concentration of 5 x 10 -3 mol / L sodium borohydride solution; at the same time prepare 10mL concentration of 5×10 -2 mol / L hydrazine hydrate solution; under the condition of magnetic stirring, first add 0.4mL of the above-mentioned sodium borohydride solution dropwise to the above-mentioned chloroplatinic acid solution, after reacting for 5min, then add 2.6mL of the above-mentioned hydrazine hydrate solution to the above-mentioned chloroplatinic acid solution Hydrazine solution, continue to react for 40min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com