Nickel-cobalt oxide material and preparation method thereof

A nickel-cobalt oxide and nickel salt technology, which is applied in the field of nickel-cobalt oxide materials and their preparation, can solve the problems of poor rate performance of supercapacitors, and achieves the advantages of high current charge and discharge, high effective contact area and porosity, and good performance. Effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

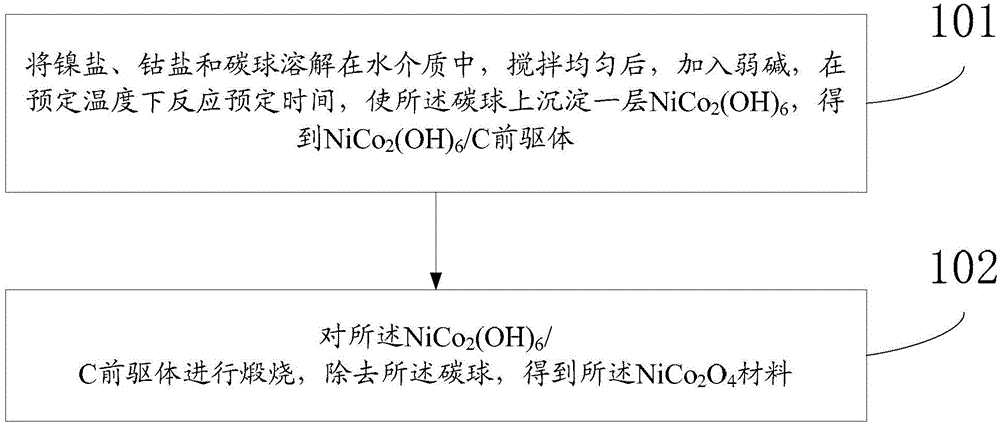

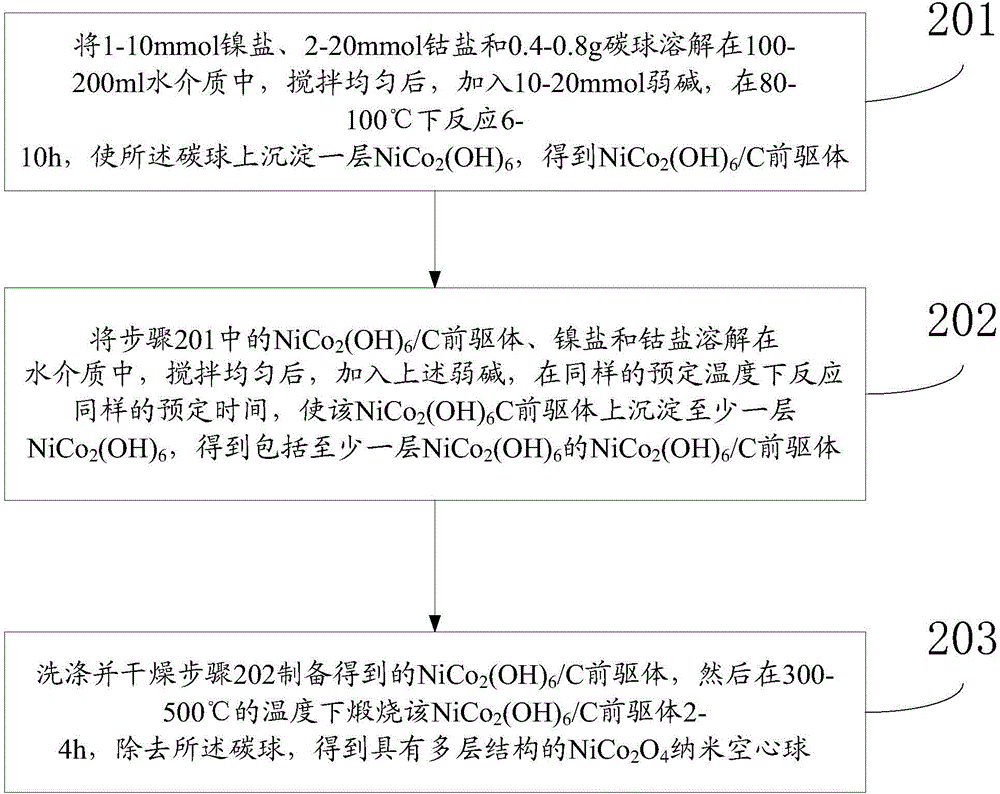

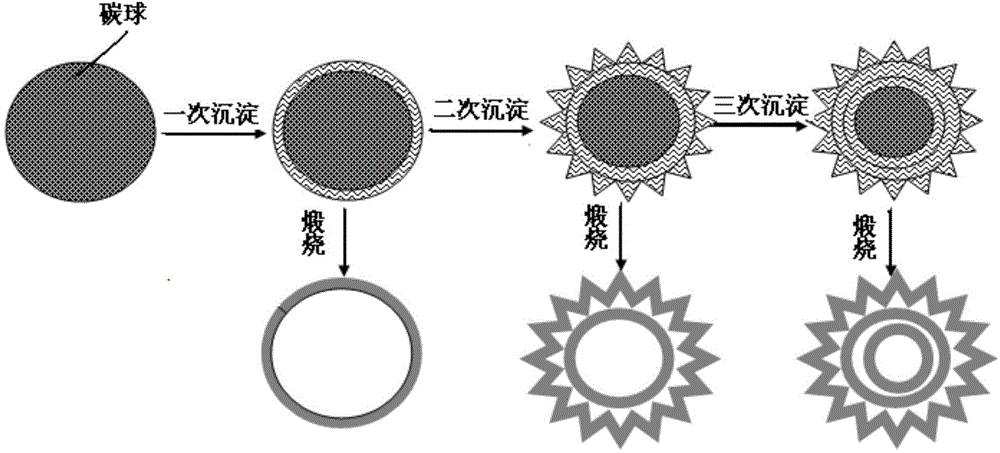

[0041] In a third aspect, an embodiment of the present invention provides a NiCo 2 O 4 Materials preparation method, attached figure 1 A flow diagram was prepared for the method. as attached figure 1 As shown, the method includes:

[0042] Step 101: Dissolve nickel salt, cobalt salt and carbon spheres in an aqueous medium, stir evenly, add a weak base, and react at a predetermined temperature for a predetermined time, so that a layer of NiCo is precipitated on the carbon spheres 2 (OH) 6 , get NiCo 2 (OH) 6 / C precursor.

[0043] Step 102, to the NiCo 2 (OH) 6 / C precursor is calcined to remove the carbon spheres to obtain the NiCo 2 O 4 Material.

[0044] The method provided by the embodiment of the present invention forms NiCo on the carbon sphere by forming 2 (OH) 6 , which is conducive to the formation of NiCo with a layered structure 2 O 4 Nano hollow spheres make it have high effective contact area and porosity. The method provided by the embodiment of t...

Embodiment 1

[0062] Dissolve 3 g of glucose and 0.3 g of cetyl ammonium bromide in 40 ml of distilled water, and stir until the solution is clear. The solution was transferred to an autoclave and kept at 180°C for 7h. After the reaction kettle was naturally cooled to room temperature, the precipitate was taken out, washed several times with distilled water and ethanol, and dried at 60° C. for 12 hours to obtain carbon spheres.

[0063] 1 mmol NiCl 2 , 2mmolCoCl 2 Dissolve in 100 ml of distilled water, add 0.4 g of carbon balls, stir by ultrasonic for 30 min, and then add 10 mmol of ammonia water and ultrasonically stir for 30 min to obtain a suspension. The suspension was transferred to biscuits, sealed and heated to 80°C for 10h. Finally, the suspension was naturally cooled to room temperature, the obtained product was centrifuged, washed several times with distilled water and ethanol, and dried at 60°C to obtain NiCo 2 (OH) 6 / C, as the preparation of monolayer NiCo 2 O 4 NiCo in ...

Embodiment 2

[0066] Dissolve 3 g of glucose and 0.3 g of cetyl ammonium bromide in 40 ml of distilled water, and stir until the solution is clear. The solution was transferred to an autoclave and kept at 180°C for 7h. After the reaction kettle was naturally cooled to room temperature, the precipitate was taken out, washed several times with distilled water and ethanol, and dried at 60° C. for 12 hours to obtain carbon spheres.

[0067] 5mmol Ni(NO 3 ) 2 , 10mmol Co(NO 3 ) 2 Dissolve in 150 ml of distilled water, add 0.6 g of carbon balls, stir with ultrasonic for 30 min, and then add 10 mmol of urea with ultrasonic stirring for 30 min to obtain a suspension. The suspension was transferred to the biscuits, sealed well and heated to 90°C for 8h. Finally, the suspension was naturally cooled to room temperature, the obtained product was centrifuged, washed several times with distilled water and ethanol, and dried at 60 °C to obtain NiCo 2 (OH) 6 / C. The resulting NiCo 2 (OH) 6 / C was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com