A kind of preparation method of aluminum oxide granulation powder special for hot-pressed water valve sheet

A technology of alumina powder and alumina, which is applied in the field of preparation of alumina granulation powder for hot-pressed water valves, can solve the problems of inconsistent wax content in semi-finished products, uneven dry grinding of powder fineness, and low efficiency of ball milling. Achieve the effects of solving precipitation and uneven mixing, particle shape correction, and wide firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

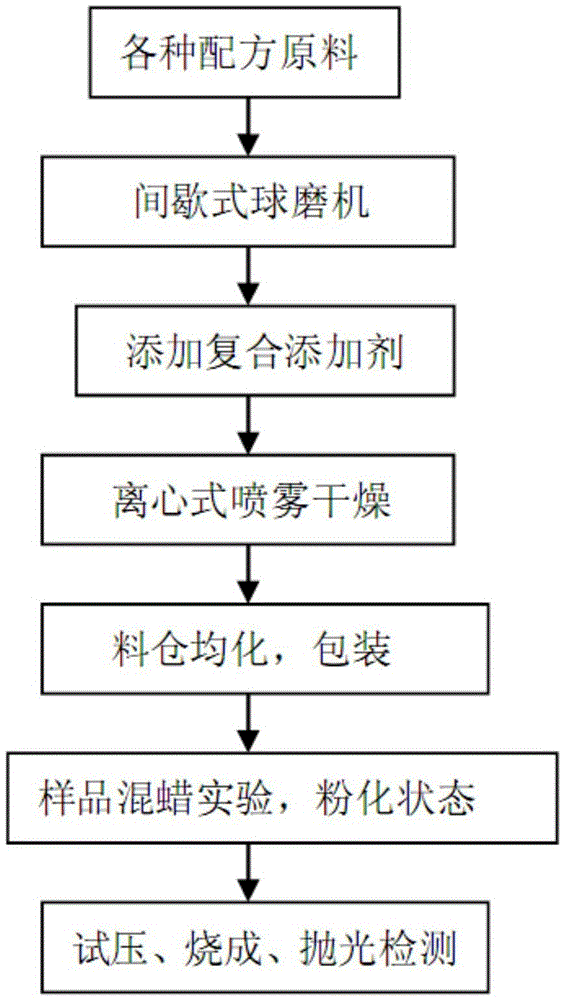

Method used

Image

Examples

Embodiment 1

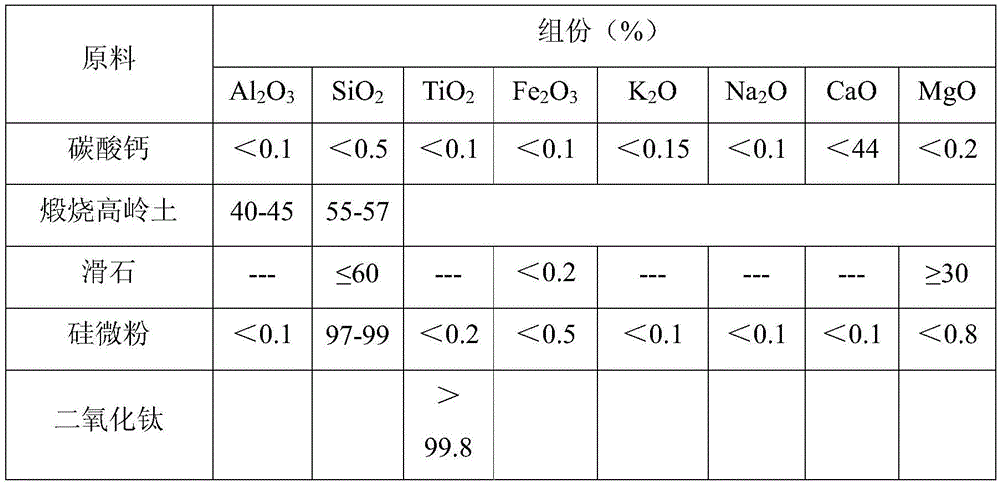

[0044] (1) Raw materials and parts by weight

[0045] Main ingredients: 91.5 parts of alumina powder, 3.6 parts of calcined kaolin;

[0046] Composite sintering aid: 1.5 parts of magnesium oxide, 1.2 parts of calcium carbonate, 1 part of silicon micropowder, 1.2% of titanium dioxide;

[0047](2) Put the alumina powder, calcined kaolin and composite sintering aid into the batch ball mill for controlled crystal ball milling (using alumina balls as the grinding medium, material: ball: water = 1: 2.6: 1) The gradation size ratio of the alumina ball stone is: φ20 accounts for 20%, φ25 accounts for 25%, φ30 accounts for 5%, φ35 accounts for 5%, φ40 accounts for 25%, φ45 accounts for 20%), after ball milling to the specified time, Detect the slurry moisture, fineness and fineness gradation. The overall size is 3000*4500mm, the rotation speed is 13r / min, the ball milling time is 15 hours, the slurry fineness D90<10μm, and the slurry moisture is controlled at about 33%.

[0048] (3) ...

Embodiment 2

[0053] (1) Raw materials and parts by weight

[0054] Main ingredients: 90 parts of alumina powder, 3.6 parts of calcined kaolin;

[0055] Composite sintering aid: 2 parts of magnesium oxide, 2.2 parts of calcium carbonate, 1 part of silicon micropowder, 1.2% of titanium dioxide;

[0056] (2) Put the alumina powder, calcined kaolin and composite sintering aid into the batch ball mill for controlled crystal ball milling (using alumina balls as the grinding medium, material: ball: water = 1: 2.6: 1) The gradation size ratio of the alumina ball stone is: φ20 accounts for 20%, φ25 accounts for 25%, φ30 accounts for 5%, φ35 accounts for 5%, φ40 accounts for 25%, φ45 accounts for 20%), after ball milling to the specified time, Detect the slurry moisture, fineness and fineness gradation. The overall size is 3000*4500mm, the rotation speed is 13r / min, the ball milling time is 25 hours, the slurry fineness D90<8μm, and the slurry moisture is controlled at about 33.5%.

[0057] (3) Ad...

Embodiment 3

[0062] (1) Raw materials and parts by weight

[0063] Main ingredients: 89 parts of alumina powder, 6 parts of calcined kaolin;

[0064] Composite sintering aids: 1.3 parts of magnesium oxide, 1.3 parts of calcium carbonate, 1.2 parts of silicon micropowder, 1.2% of titanium dioxide;

[0065] (2) Put the alumina powder, calcined kaolin and composite sintering aid into the batch ball mill for controlled crystal ball milling (using alumina ball stone as the grinding medium, material: ball: water = 1: 2.2: 1) The gradation size ratio of the alumina ball stone is: φ20 accounts for 20%, φ25 accounts for 25%, φ30 accounts for 5%, φ35 accounts for 5%, φ40 accounts for 25%, φ45 accounts for 20%), after ball milling to the specified time, Detect the slurry moisture, fineness and fineness gradation. The overall size is 3000*4500mm, the rotation speed is 13r / min, the ball milling time is 23 hours, the slurry fineness D90<6μm, and the slurry moisture is controlled at about 40%.

[0066]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com