Comprehensive Utilization Process of Petroleum Coke Calcination

A petroleum coke and calcination technology, which is applied in the field of petroleum coke calcination comprehensive utilization process, can solve the problems of insufficient exhaust gas preheating, unstable product quality, insufficient strength, etc., and achieve energy utilization rate improvement, increase strength, and increase true density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A petroleum coke calcination comprehensive utilization process, the steps of which are:

[0022] (1) Separately crush different types of petroleum coke to a particle size of 5-30mm, and then remove iron,

[0023] (2) Blending different types of petroleum coke to obtain mixed petroleum coke, the ash content of the mixed petroleum coke after blending is not more than 0.4%, and the volatile matter is controlled at 10.5-11%; 0.005-0.01% of mixed rare earths, 0.005-0.006% of its weight silicon carbide; the mixed rare earths are composed of yttrium, berkelium and lanthanum, and the mass ratio of the three is 1: (0.1-0.15): (0.25-0.30 ); the silicon carbide is selected from α-SiC particles with a particle size of 5-10 μm;

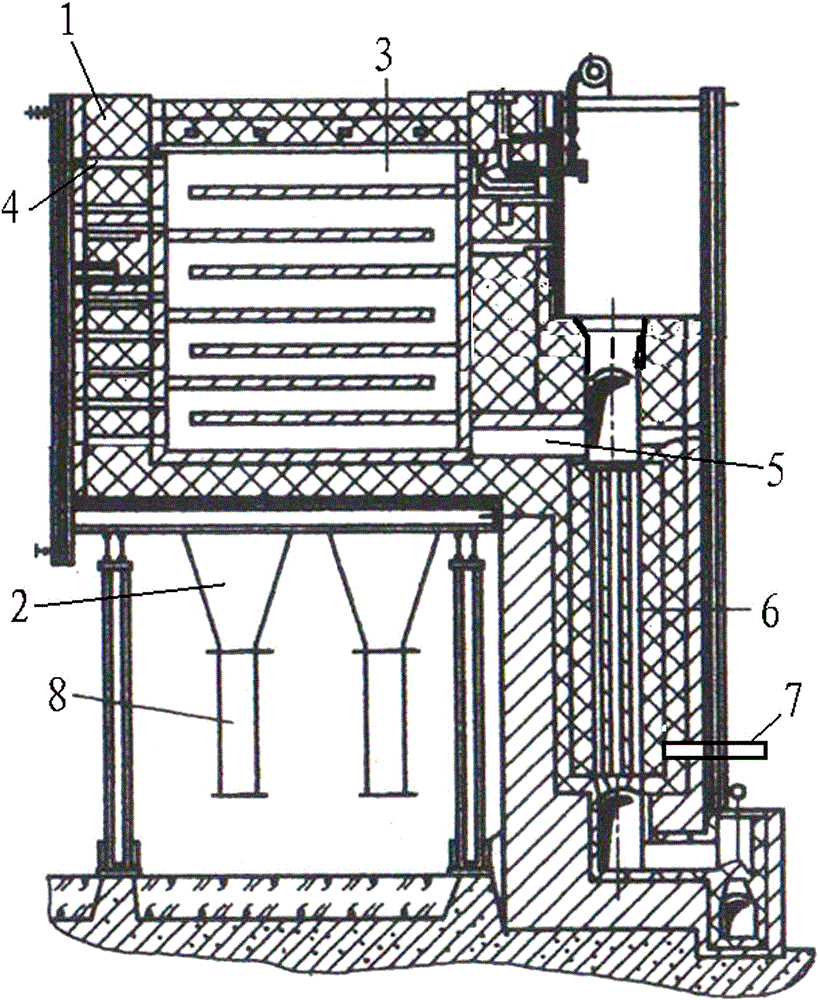

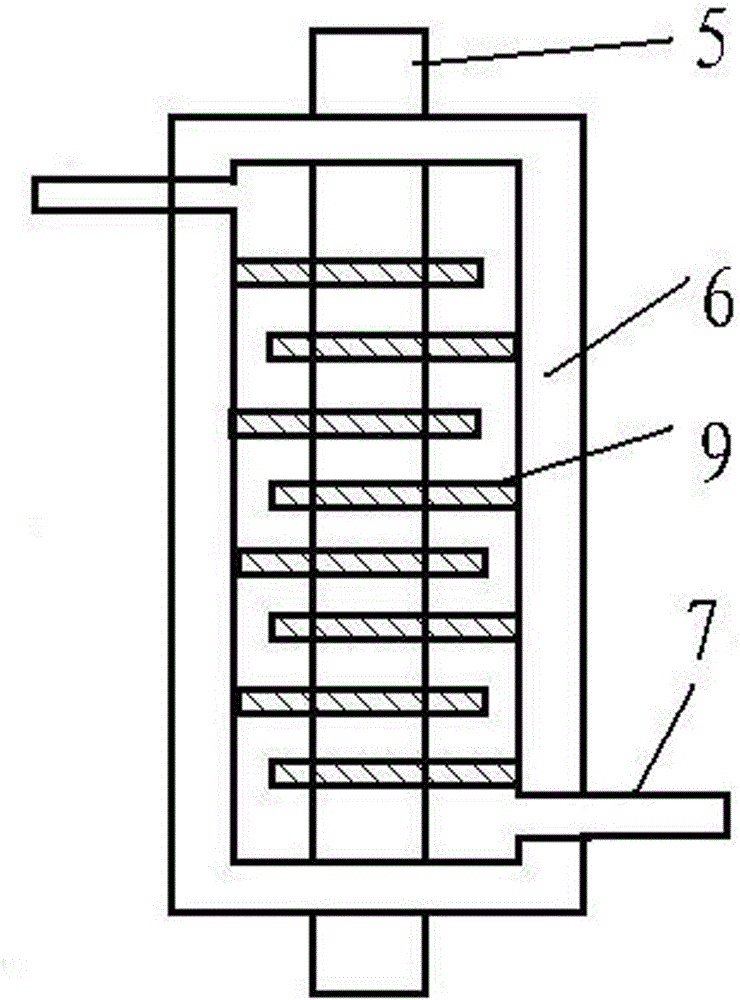

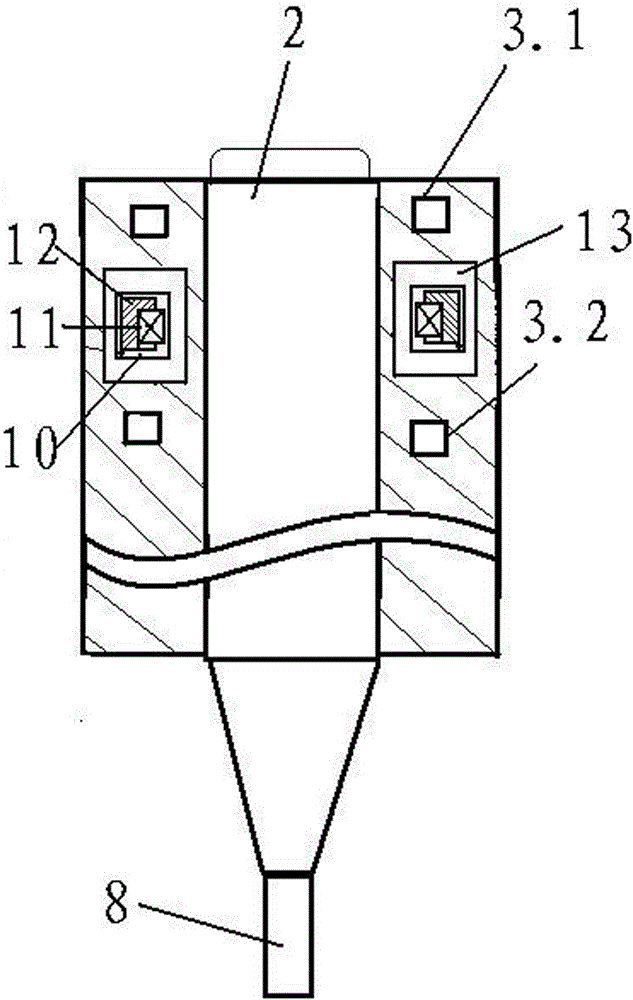

[0024] (3) The blended mixed petroleum coke is intermittently or continuously introduced into the eight-layer down-flow pot calciner through the top feeding mechanism. The down-flow pot calciner includes refractory bricks (silica bricks) The outer furnace...

Embodiment 2

[0028] Other steps remain unchanged, the difference from Example 1 is that in step 1, the petroleum coke is crushed to a particle size of 5-10mm.

Embodiment 3

[0030]Other steps remain unchanged, and the difference from Example 1 is that the refractory bricks are made through the following steps: 30-35 parts by weight of Portland cement, 18-21 parts by weight of fly ash, 14-16 parts by weight of Silicon carbide, 20-25 parts by weight of alumina, 5-10 parts by weight of magnesium oxide, 5-6 parts by weight of silicon dioxide, 3-5 parts by weight of vermiculite powder, 2-4 parts by weight of zirconia, 1-2 Parts by weight of graphite and 0.5-1 part by weight of titanium dioxide are mixed into a mixed powder, and then a binder accounting for 5-6% of the total weight of the mixed powder is added. After forming by a hydraulic press, it is dried and sintered to obtain a finished product. The temperature of sintering is controlled At 1420-1450°C, the time is 2-3 hours. It has been tested that the refractoriness of this refractory brick reaches 1750-1800°C, which is higher than the 1690-1710°C of conventional silica bricks, and when heated fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com