A kind of mof composite electrode catalytic water splitting method for hydrogen production and hydrogen storage

A composite electrode, MOF technology, applied in the direction of electrode shape/type, electrolysis process, electrolysis components, etc., can solve problems such as hindering the construction and improvement of hydrogen energy system, low energy efficiency, poor atom economy, etc., to promote research and industrialization process. , the experimental effect is good, the effect of mild suction and release conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

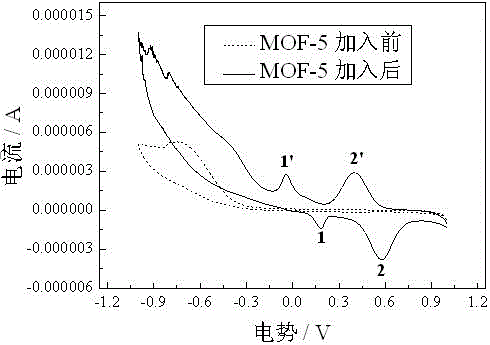

[0025] Firstly, the 1cm×8cm nickel mesh was washed in acetone, pickling solution (HNO 3 :H 2 O=1:3, volume ratio) and distilled water were ultrasonically treated for 20 minutes to remove impurities such as oil and oxides on the surface of the nickel mesh, and a mixture of MOF-5 and graphite powder with a mass ratio of 1:2 was placed in an agate mortar Mix, add 10ml of absolute ethanol, ultrasonically disperse for 30 minutes, then add a certain amount of polytetrafluoroethylene dispersion (PTFE, 60%) under heating and constant stirring, evaporate the alcohol until the mixture becomes a paste, and then prepare A good MOF active mixture is coated on the treated nickel mesh, loaded into a special mold, and pressed into a 1mm thick sheet under a certain pressure. o C roasting for 4h, cooled and taken out for later use. Take 1mol / L sulfuric acid solution as the electrolyte and place it in a closed electrolytic cell, pass N 2 Gas for 10 minutes to remove the air mixed in the elect...

Embodiment approach 2

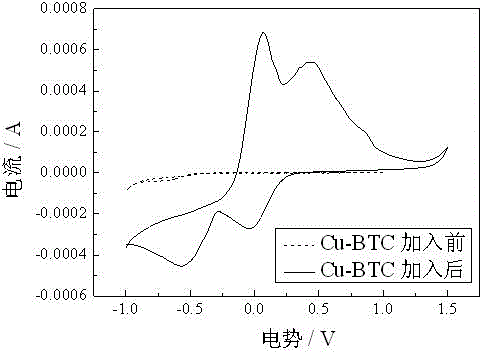

[0028] Firstly, the 1cm×8cm nickel mesh was washed in acetone, pickling solution (HNO 3 :H 2 O=1:3, volume ratio) and distilled water were ultrasonically treated for 20 minutes to remove impurities such as oil and oxides on the surface of the nickel mesh, and a mixture of Cu-BTC and graphite powder with a mass ratio of 1:1 was placed in an agate mortar Mix, add 10ml of absolute ethanol, ultrasonically disperse for 30 minutes, then add a certain amount of polytetrafluoroethylene dispersion (PTFE, 60%) under heating and constant stirring, evaporate the alcohol until the mixture becomes a paste, and then prepare A good MOF active mixture is coated on the treated nickel mesh, loaded into a special mold, and pressed into a 1mm thick sheet under a certain pressure. o C roasting for 4h, cooled and taken out for later use. Take 1mol / L sulfuric acid solution as the electrolyte and place it in a closed electrolytic cell, pass N 2 Gas for 10 minutes to remove the air mixed in the elec...

Embodiment approach 3

[0031] Firstly, the 1cm×8cm nickel mesh was washed in acetone, pickling solution (HNO 3 :H 2 O=1:3, volume ratio) and distilled water were ultrasonically treated for 20 minutes to remove oil and oxide impurities on the surface of the nickel mesh, and a mixture of Cu-BTC and superconducting carbon black with a mass ratio of 1:2 was placed in the agate laboratory. Mix in a bowl, add 10ml of absolute ethanol, ultrasonically disperse for 30 minutes, then add a certain amount of polytetrafluoroethylene dispersion (PTFE, 60%) under heating and constant stirring, evaporate the alcohol until the mixture becomes a paste, and then Apply the prepared MOF active mixture on the treated nickel mesh, put it into a special mold, and press it into a 1mm thick sheet under a certain pressure. o C roasting for 4h, cooled and taken out for later use. Take 0.5mol / L NaCl solution as the electrolyte and place it in a closed electrolytic cell, pass N 2 Gas for 10 minutes to remove the air mixed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com