Crucible for growing cadmium selenide crystal and growing method of cadmium selenide crystal

A cadmium selenide and crucible technology, which is applied in the field of infrared and nonlinear optical crystal preparation, can solve the problems of polycrystalline material volatilization, furnace pollution, CdSe melt leakage, etc., achieve excellent pressure resistance, avoid melt leakage, and conduct heat sexually superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

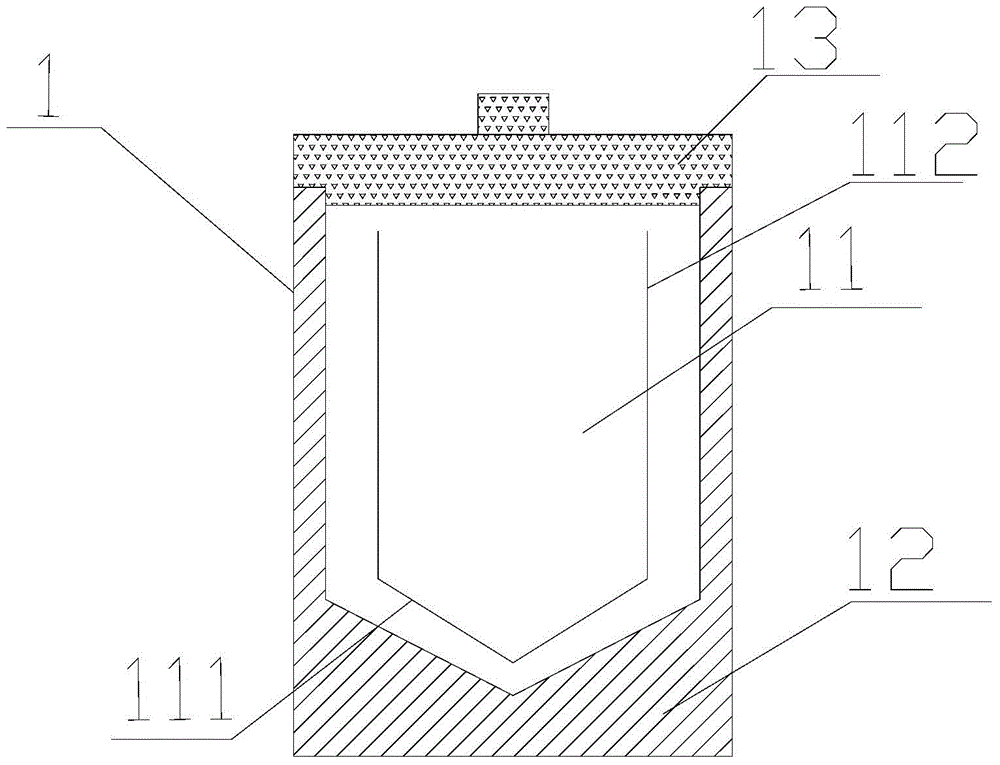

[0136] This embodiment provides a first type of crucible 1 for growing cadmium selenide crystals, with figure 1 Schematic diagram of the structure of the crucible. as attached figure 1 As shown, the first type of crucible 1 includes: a first inner crucible 11 made of pyrolytic boron nitride, a first outer crucible 12 of molybdenum material set outside the first inner crucible 11, and a first outer crucible for sealing The first crucible cover 13 of the first outer crucible 12, a gap with a width of 1.2mm is provided between the first outer crucible 12 and the first inner crucible 11;

[0137] The first inner layer crucible 11 includes a tapered tip portion 111 with a cone angle of 60° and a first column portion 112 for cadmium selenide crystal growth, the first column portion 112 is a hollow cylinder with an inner diameter of 100mm , with an equal-diameter length of 400mm, set on the tapered tip portion 111;

[0138] The wall thickness of the first outer layer crucible 12 i...

Embodiment 2

[0140] This embodiment also provides a first type of crucible 1 for growing cadmium selenide crystals, except that the first type of crucible 1 provided by this embodiment and the first type of crucible 1 provided by embodiment 1 have the following distinguishing features: The rest of the structures are the same, so the structure of the crucible provided in this embodiment can also refer to the attached figure 1 .

[0141] Among them, these distinguishing features are: the material of the first inner layer crucible 11 is graphite; the cone angle of the tapered tip portion 111 of the first inner layer crucible 11 is 5°; The inner diameter of the part 112 is 10mm, and the equal diameter length is 50mm; the material of the first outer layer crucible 12 is an alloy of molybdenum and tungsten; the wall thickness of the first outer layer crucible 12 is 3mm; and the first outer layer crucible 12 and the first The gap between the inner crucibles 11 is 2 mm.

Embodiment 3

[0143] This embodiment also provides a first type of crucible 1 for growing cadmium selenide crystals, except that the first type of crucible 1 provided by this embodiment and the first type of crucible 1 provided by embodiment 1 have the following distinguishing features: The rest of the structures are the same, so the structure of the crucible provided in this embodiment can also refer to the attached figure 1 .

[0144] Among them, these distinguishing features are: the cone angle of the tapered tip portion 111 of the first inner layer crucible 11 is 160°; the inner diameter of the first cylinder portion 112 of the first inner layer crucible 11 is 300mm, and the equal diameter length is 600 mm; the material of the first outer crucible 12 is iridium; the wall thickness of the first outer crucible 12 is 10 mm; and the gap between the first outer crucible 12 and the first inner crucible 11 is 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com