High-density and high-uniform ingan quantum dot structure and growth method

A growth method and quantum dot technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of obtaining high-density, high-uniformity and high-quality InGaN quantum dot materials, restricting the development and application of InGaN quantum dot devices, Problems such as quantum dot damage in processing technology, to achieve the effect of improving device performance, good uniformity, and uniformity without damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

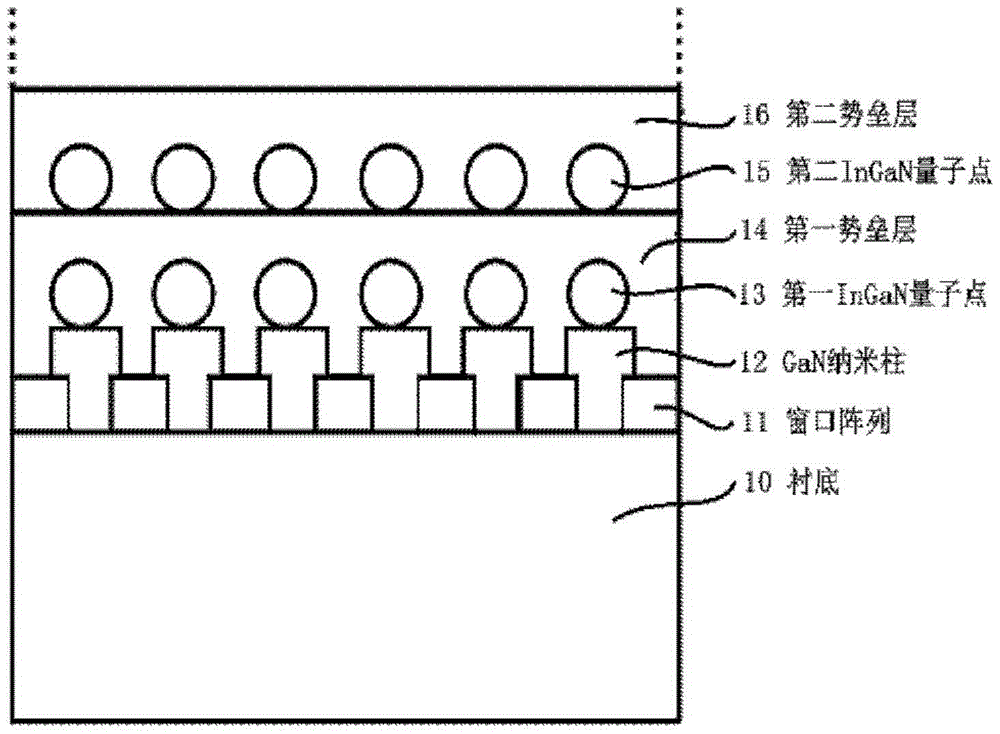

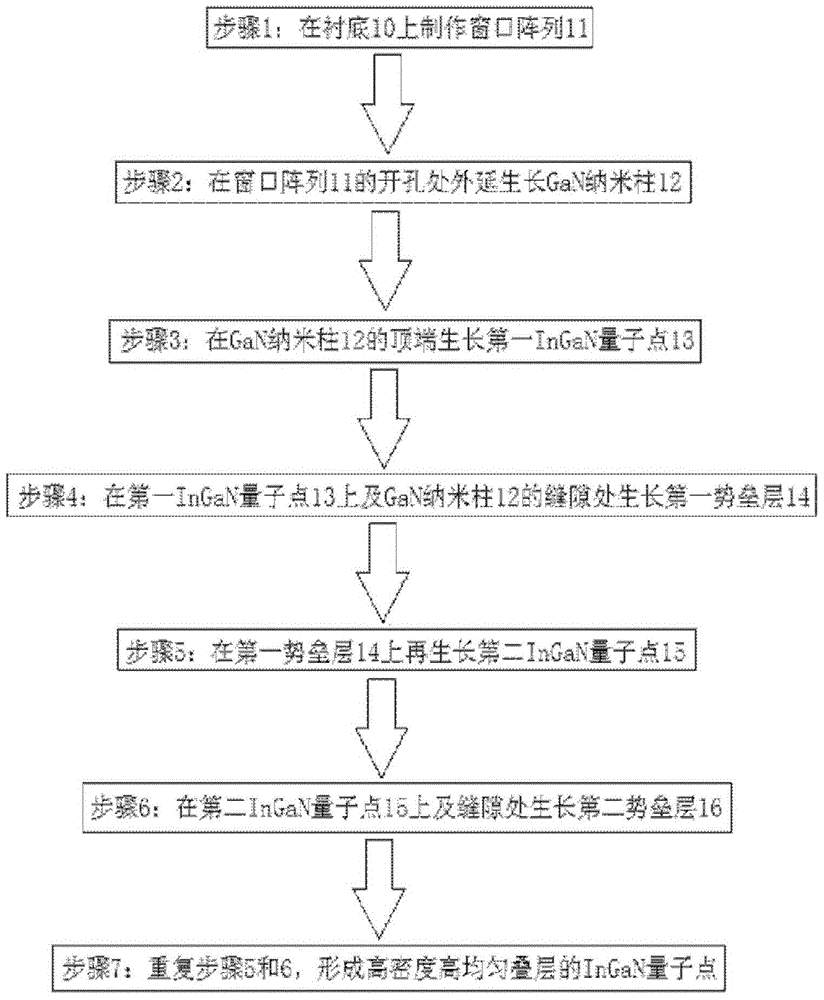

[0030] see figure 1 As shown, the present invention provides a high-density and highly uniform InGaN quantum dot structure, comprising:

[0031] A substrate 10, the material of which can be sapphire, silicon, silicon carbide, gallium nitride or gallium arsenide;

[0032] A window array 11, which is made on the substrate 10, wherein the material of the window array 11 is SiN x or SiO 2 , the aperture of the window array 11 is less than 100nm, and the thickness is about 0.1-5μm. The pattern of the window array 11 is made by electron beam exposure or nanoimprinting technology, so it is possible to obtain tiny windows with extremely high resolution nanoscale dimensions. By adjusting The size and density of the window can change the size and position distribution of quantum dots to realize the regulation of the physical properties of the entire material;

[0033] A GaN nanocolumn 12, which grows at the opening of the window array 11 and is in contact with the surface of the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com