Active carbon preparation method and giant reed active carbon

An activated carbon and a technology for preparing activated carbon, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cost, long preparation process, limited supply of raw materials, etc., achieve low cost and increase additional economic value , The effect of broadening the source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] In the following examples, the production of reed bamboo activated carbon comprises the following steps:

[0015] Step (1), preprocessing. After the reed bamboo is harvested, the leaves are removed, the stems are taken out, dried in the sun for 1 to 2 days to remove moisture, then crushed into powder, and sieved to 20 mesh.

[0016] Step (2), carbonization. Mix Arundis powder and carbonization furnace bottom ash in a certain proportion, and send them to the carbonization furnace for carbonization. The carbonization furnace bottom ash used can be the bottom ash after burning various biomass fuels (such as sawdust, abandoned wetland plants) that provide heat for the carbonization process. The mixing amount (mass fraction) of bottom ash is 10-30%. The carbonization process is carried out under the condition of cutting off the air, the temperature of the carbonization furnace is 400-600°C, and the carbonization time is 10-30 minutes.

[0017] Step (3), activation. Cont...

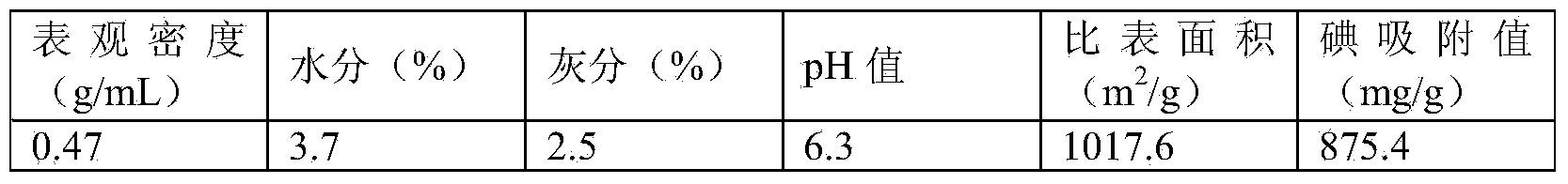

Embodiment 1

[0023] Naturally sun-dried reed bamboo was crushed into powder, sieved to 20 mesh, mixed with 30% carbonization furnace bottom ash, and then carbonized. The temperature of the carbonization furnace was 600°C, and the carbonization time was 10 minutes. Continue to pass in the mixed gas of air and water vapor for activation, the concentration of water vapor is 15%, the activation temperature is 800°C, and the activation time is 30 minutes. After the carbonization furnace is naturally cooled to room temperature, the carbonized material is taken out, subjected to winnowing and separation, pickling and deashing, rinsing, and drying to obtain the finished Arundis activated carbon.

Embodiment 2

[0025] Naturally sun-dried reed bamboo was crushed into powder, sieved to 20 mesh, mixed with 20% carbonization furnace bottom ash, and then carbonized. The temperature of the carbonization furnace was 500°C, and the carbonization time was 20 minutes. Continue to pass in the mixed gas of air and water vapor for activation, the water vapor concentration is 10%, the activation temperature is 800°C, and the activation time is 60 minutes. After the carbonization furnace is naturally cooled to room temperature, the carbonized material is taken out, subjected to winnowing and separation, pickling and deashing, rinsing, and drying to obtain the finished Arundis activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com