Preparation method of graphene/polyimide composite adhesive

A composite adhesive and polyimide technology, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., to expand the application prospects, the preparation process is simple and efficient, and the dispersion and compatibility are improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

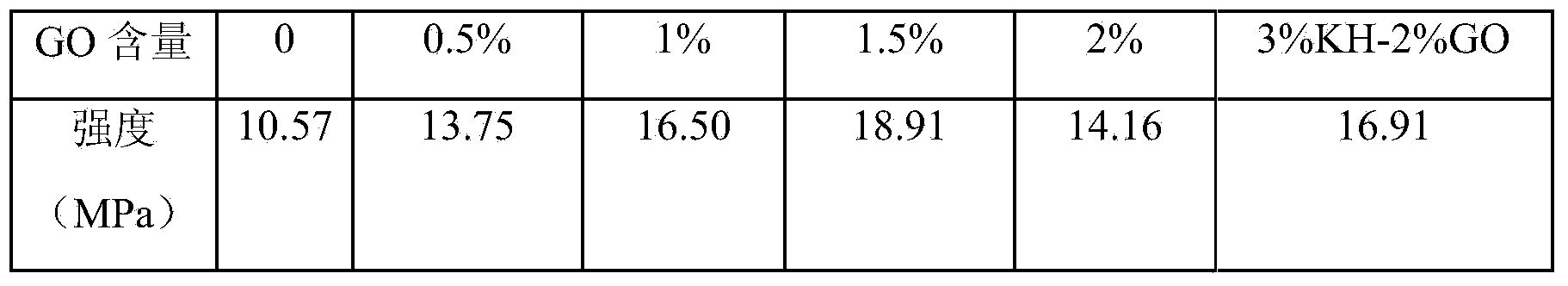

Embodiment 1

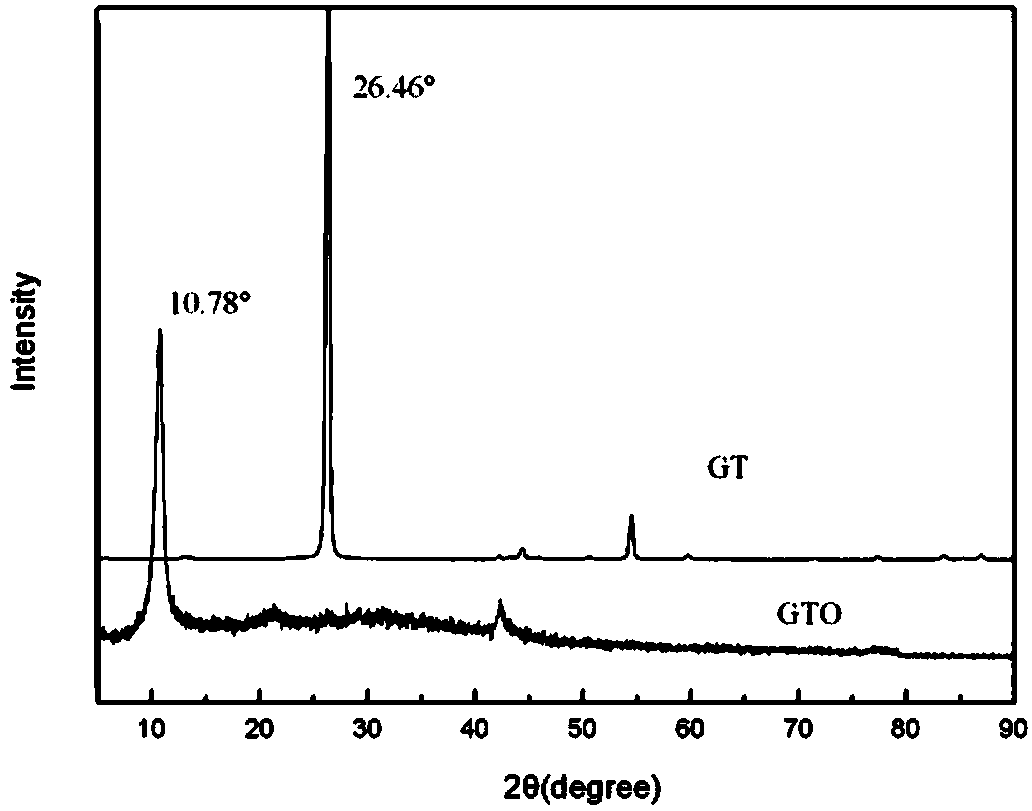

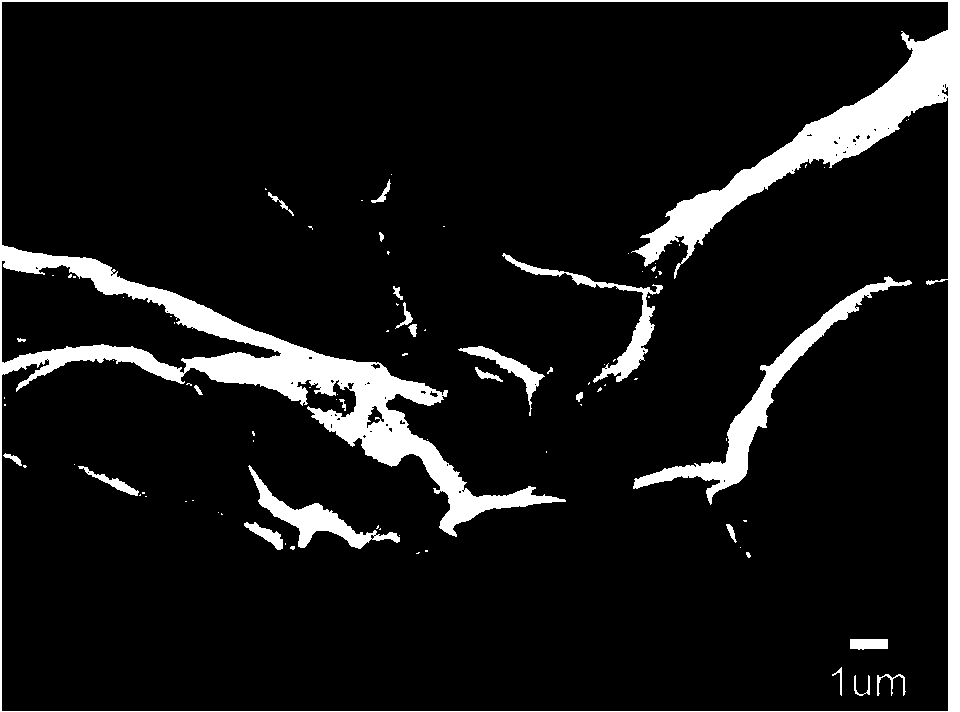

[0030] (a) Preparation and surface modification of graphene oxide

[0031] Prepare graphite oxide by the improved Hummers method, take 10mg of graphite oxide, add it to 10ml DMAC or DMF organic solvent, and ultrasonically strip it for 3 hours to obtain a suspension of GO / DMAC; then add an appropriate amount of silane coupling agent diluent, KH-550 is 1% of the mass of graphene oxide was fully stirred in a water bath at 70°C for 1 hour to obtain an undried sticky substance.

[0032] (b) Ultrasonic blending of modified graphene oxide and polyamic acid in ice bath

[0033] Add polyamic acid to the above-mentioned dope, the quality of the modified graphene is 2.5% of the polyamic acid quality, after stirring for 5min, ultrasonically blend in the ice bath for 0.5h to obtain a stable suspension which is graphene / polyamic acid. Precursors for imide composites.

[0034] (c) Vacuum thermal imidization of polyamic acid and in situ thermal reduction of graphene oxide

[0035] In the v...

Embodiment 2

[0037] (a) Preparation and surface modification of graphene oxide

[0038] Prepare graphite oxide by the improved Hummers method, take 10mg graphite oxide, add it to 10ml DMAC or DMF organic solvent, and ultrasonically strip it for 2 hours to obtain a suspension of GO / DMAC; then add an appropriate amount of silane coupling agent diluent, KH-550 is 2% of the mass of graphene oxide, fully stirred in a water bath at 60°C for 2 hours to obtain an undried sticky substance.

[0039] (b) Ultrasonic blending of modified graphene oxide and polyamic acid in ice bath

[0040] Add polyamic acid to the above-mentioned viscous substance, the quality of modified graphene is 2% of the mass of polyamic acid, after stirring for 5 minutes, ultrasonically blend in ice bath for 1 hour to obtain a stable suspension that is graphene / polyamide Precursors for imine composites.

[0041] (c) Vacuum thermal imidization of polyamic acid and in situ thermal reduction of graphene oxide

[0042] In the va...

Embodiment 3

[0044] (a) Preparation and surface modification of graphene oxide

[0045] Graphite oxide was prepared by the improved Hummers method. Take 5mg of graphite oxide, add it to 10ml DMAC or DMF organic solvent, and ultrasonically strip it for 1h to obtain a suspension of GO / DMAC; then add an appropriate amount of silane coupling agent diluent, KH-550 is 3% of the mass of graphene oxide, fully stirred in a water bath at 60°C for 2 hours to obtain an undried sticky substance.

[0046] (b) Ultrasonic blending of modified graphene oxide and polyamic acid in ice bath

[0047] Add polyamic acid to the above-mentioned dope, the quality of modified graphene is 0.5% of polyamic acid quality, after stirring for 10min, ultrasonically blend in ice bath for 1.5h to obtain a stable suspension which is graphene / polyamic acid. Precursors for imide composites.

[0048] (c) Vacuum thermal imidization of polyamic acid and in situ thermal reduction of graphene oxide

[0049] In the vacuum oven, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com