Graphene-protein derived carbon supercapcaitor material and preparation method thereof

A supercapacitor and protein technology, which is used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of complex composite effects and unsatisfactory composite methods, and achieve good rate performance and cycle stability. Atomic doping, the effect of considerable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Prepare an aqueous solution of mulberry silk protein with a mass fraction of 4%. Prepare graphene oxide with a mass fraction of 0.4% and a size of 200 nm.

[0027] 2. Under stirring at room temperature, the above two solutions were mixed under the condition of pH=8, and the two were mixed at a volume ratio of 1:1 to obtain a mixed solution of silkworm silk protein and graphene oxide.

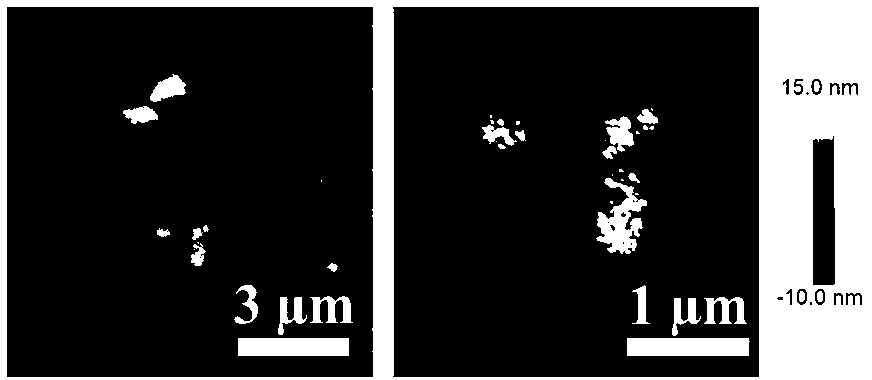

[0028] 3. Add sodium citrate for reduction, the reduction temperature is 100°C, and react for 3 hours. After the reaction, a silkworm silk protein-reduced graphene oxide solution is obtained. Figure 1 An atomic force microscope image of this composite solution, showing silkworm silk protein wrapping around reduced graphene oxide to prevent its large sheets from aggregating.

[0029] 4. Add NaOH to the composite solution obtained above, and the solid content ratio of the composite solution is 1:1, stir for 0.5h, and vacuum dry at room temperature.

[0030] 5. Carbonize the above drie...

Embodiment 2

[0036] 1. Prepare an aqueous solution of mulberry silk protein with a mass fraction of 10%. Prepare graphene oxide with a mass fraction of 1% and a size of 200 nm.

[0037]2. Under stirring at room temperature, the above two solutions were mixed under the condition of pH=8, and the two were mixed at a volume ratio of 1:2 to obtain a mixed solution of silkworm silk protein and graphene oxide.

[0038] 3. Add hydrazine hydrate for reduction, the reduction temperature is 80°C, and react for 6 hours. After the reaction is completed, a silkworm silk protein-reduced graphene oxide solution is obtained.

[0039] 4. Add KOH to the composite solution obtained above, and the solid mass ratio of the composite solution to the composite solution is 2:1, stir for 0.5h, and freeze-dry.

[0040] 5. Carbonize the above dried composite. Under a nitrogen atmosphere, the temperature is 700° C., and the heating rate is 10° C. / min. Carbonization time is 3h. After carbonization, wash with water ...

Embodiment 3

[0045] 1. Prepare an aqueous solution of mulberry silk protein with a mass fraction of 6%. Graphene oxide was prepared with a mass fraction of 0.6% and a size of 200 nm.

[0046] 2. Under stirring at room temperature, the above two solutions were mixed under the condition of pH=8, and the two were mixed at a volume ratio of 1:10 to obtain a mixed solution of mulberry silk protein and graphene oxide.

[0047] 3. Add NaOH to the compound solution obtained above, and the solid content ratio of the compound solution to the compound solution is 5:1. The reduction reaction was carried out at a temperature of 80° C. for 24 hours. After the reaction, a silkworm silk protein-reduced graphene oxide solution was obtained.

[0048] 4. Carbonize the above dried composite. Under a nitrogen atmosphere, the temperature is 700° C., and the heating rate is 10° C. / min. Carbonization time is 3h. After carbonization, wash with water and ethanol repeatedly. Under the condition of 30° C. in a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com