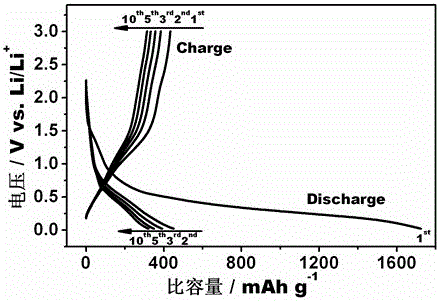

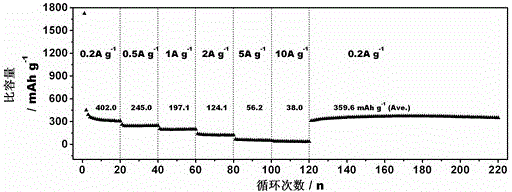

A kind of graphene/zinc oxide composite negative electrode material for lithium ion battery and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in the field of graphene/zinc oxide composite negative electrode material for lithium ion battery and its preparation, can solve the problems of poor charge-discharge cycle characteristics, low capacity reversibility, large volume expansion, etc. The effect of avoiding poor ohmic contact, controllable doping amount and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 74.35 mg of zinc nitrate (Zn(NO) with a purity of 98% 3 ) 2 ·6H 2 (2) and 5.09mg purity are 99% graphene oxide powder, be dissolved together in the mixed solution that 10.0ml purity is 99.5% 1,2-propanediol and 10.0ml purity is the dehydrated alcohol of 99.5%, this mixed solution is used After 1 hour of ultrasonic agitation with a power of 700 W and a frequency of 50 Hz, a suspended ESD precursor solution was formed. A copper foil with a diameter of 15mm, a thickness of 1mm, and a purity of 98% (as a metal substrate) was weighed and fixed on the substrate splint, and then the metal substrate was heated to 100°C. The distance between the capillary nozzle and the metal substrate was adjusted to 7cm, and the applied DC voltage was 9kV. Set the spray speed of the liquid flow to 600 μl / h, turn on the switch, and the ESD device starts to spray the ESD precursor liquid onto the metal substrate. After 1 hour of spraying, the ESD apparatus was turned off. After the sample i...

Embodiment 2

[0033] 74.35 mg of zinc nitrate (Zn(NO) with a purity of 98% 3 ) 2 ·6H 2 (2) and 2.26mg purity are 99% graphene oxide powder, be dissolved together in the mixed solution that 13.3ml purity is 99.5% 1,2-propanediol and 6.7ml purity is the dehydrated alcohol of 99.5%, this mixed solution is used After 1.5 hours of ultrasonic stirring with a power of 750W and a frequency of 40 Hz, a suspended ESD precursor solution was formed. The nickel foam (as the metal substrate) with a diameter of 15 mm, a thickness of 2 mm, and a purity of 98% was weighed and fixed on the substrate splint, and then the metal substrate was heated to 250 °C. The distance between the capillary nozzle and the metal substrate was adjusted to be 5 cm, and the applied DC voltage was 11 kV. Set the spray speed of the liquid flow to 800 μl / h, turn on the switch, and the ESD device starts to spray the precursor liquid onto the substrate. After 1.5 hours of spraying, the ESD apparatus was turned off. After the sa...

Embodiment 3

[0036] 74.35 mg of zinc nitrate (Zn(NO) with a purity of 98% 3 ) 2 ·6H 2 (2) and 3.59mg purity are 99% graphene oxide powder, be dissolved together in the mixed solution of 1,2-propanediol that is 99.5% purity and 13.3ml purity is the dehydrated alcohol of 99.5% in 6.7ml purity, this mixed solution is used After 2 hours of ultrasonic stirring with a power of 1000 W and a frequency of 20 Hz, a suspended ESD precursor solution was formed. The nickel foam (as the metal substrate) with a diameter of 15 mm, a thickness of 1 mm and a purity of 98% was weighed and fixed on the substrate splint, and then the metal substrate was heated to 200 °C. The distance between the capillary nozzle and the metal substrate was adjusted to 6 cm, and the applied DC voltage was 12 kV. Set the spray speed of the liquid flow to 700 μl / h, turn on the switch, and the ESD device starts to spray the precursor liquid onto the metal substrate. After 2 hours of spraying, the ESD apparatus was turned off. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com