A kind of hierarchical structure graphene cage and preparation method thereof

A technology of graphene cage and graphene layer, which is applied in the field of hierarchical structure graphene cage and its preparation, can solve the problems of unsatisfactory electrical conductivity, low degree of graphitization, and low carbon crystallinity, and achieve high crystallinity Accurate, easy to operate, conducive to the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

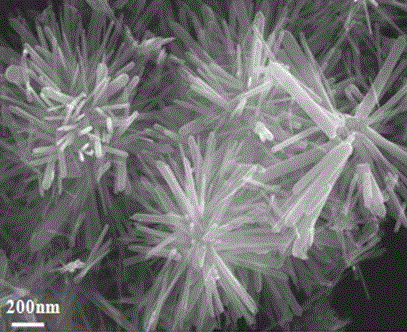

[0024] Embodiment 1: 0.9g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) and 0.24g sodium hydroxide (NaOH) are put into the beaker, add 36.4mL ethylenediamine and 18.2mL deionized water, make it fully disperse by ultrasonic in the ultrasonic cleaner, generate white suspension; Then transfer to volume 100mL Teflon-lined autoclave, put in an oven for 200 o C was heated at a constant temperature for 8 hours; the autoclave was taken out and cooled to room temperature naturally to obtain a white precipitate, which was washed with absolute ethanol and centrifuged 3 times, and o C was dried for 8 hours to obtain the secondary structure ZnO.

[0025] Place 0.1g of secondary structure ZnO in the high temperature zone of the dual temperature zone tube furnace, place 0.1g solid camphor in the low temperature zone of the dual temperature zone tube furnace; o The rate of C / min raises the temperature of the high temperature zone to 700 o C, then with 5 o The rate of C / min raises the temperature o...

Embodiment 2

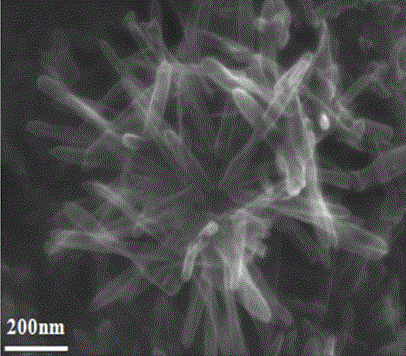

[0029] Embodiment 2: 0.48g zinc sulfate (Zn(SO 4 ) 2 ) and 0.48g sodium hydroxide (NaOH) into a beaker, add 38.5mL ethylenediamine and 12.8mL deionized water, and ultrasonically disperse it in an ultrasonic cleaner to form a white suspension; then transfer to a volume of 100mL PTFE-lined autoclave, placed in an oven for 180 o C was heated at a constant temperature for 6 hours; the autoclave was taken out and cooled to room temperature naturally to obtain a white precipitate, which was washed with absolute ethanol and centrifuged 5 times, and o C was dried for 10 hours to obtain the secondary structure ZnO.

[0030] Place 0.1g of secondary structure ZnO in the high temperature zone of the dual temperature zone tube furnace, place 0.05g solid camphor in the low temperature zone of the dual temperature zone tube furnace; o C / min rate to raise the temperature of the high temperature zone to 900 o C, then with 5 o The rate of C / min raises the temperature of the low temperature...

Embodiment 3

[0033] Embodiment 3: 0.41g zinc chloride (ZnCl 2 ) and 0.72g sodium hydroxide (NaOH) into a beaker, add 40.5mL ethylenediamine and 10.2mL deionized water, and ultrasonically disperse it in an ultrasonic cleaner to form a white suspension; then transfer to a volume of 100mL PTFE-lined autoclave, placed in an oven for 150 o C was heated at a constant temperature for 12 hours; the autoclave was taken out and cooled to room temperature naturally to obtain a white precipitate, which was washed with absolute ethanol and centrifuged 4 times, and o C was dried for 12 hours to obtain the secondary structure ZnO.

[0034] Place 0.1g of secondary structure ZnO in the high temperature zone of the dual temperature zone tube furnace, place 0.2g solid camphor in the low temperature zone of the dual temperature zone tube furnace; o C / min rate to raise the temperature of the high temperature zone to 800 o C, then with 5 o The rate of C / min raises the temperature of the low temperature zone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com