Calcium-containing effervescent tablet and preparation method and application

An effervescent preparation, calcium carbonate technology, applied in medical preparations containing active ingredients, pharmaceutical formulations, aluminum/calcium/magnesium active ingredients, etc., can solve the problem of low vitamin D, poor uniformity, and no production of effervescent tablets. methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a calcium-containing effervescent preparation, wherein the active ingredients include calcium carbonate and vitamin D. The calcium carbonate is calcium carbonate known in the art and can be used to make calcium supplement products, preferably including but not limited to high-purity Medicinal calcium carbonate, high-compressibility and high-purity medicinal calcium carbonate granules, or calcium raw material intermediate products of high-density calcium carbonate tablets, etc. Or "intermediate calcium raw materials of high-density calcium carbonate tablets" have been fully disclosed in Chinese patent applications CN200410052673.8 and CN200910200057.5 respectively, and their preparation methods have been recorded in detail. The content of these published patent applications concerning the corresponding calcium carbonate is incorporated in the present application in its entirety. The vitamin D is preferably vitamin D 3 . The effervescent p...

Embodiment 1

[0114] Preparation of acid granules

[0115] To prepare a binder solution, 23.6% by weight of amb was dissolved in ethanol to obtain 6.0% amb ethanol solution, the temperature of the solution is controlled at 23°C-27°C, more preferably 25°C, before spraying.

[0116] Put citric acid and fumaric acid in a high-speed mixer and mix for 5 minutes.

[0117] Put the mixed acid source in the wet granulation pot, put The amb ethanol solution was subjected to wet granulation at a liquid addition rate of 260ml / min to obtain acid granules.

[0118] During the wet granulation, the drying air inlet temperature is controlled at 45°C, the material temperature is controlled at 40°C, and the outlet air temperature is controlled at 20°C.

[0119] In another preferred embodiment, the wet granulation of the acid granules has a mesh size of 10-30 mesh, preferably 14-20 mesh, more preferably 16 mesh.

Embodiment 2

[0121] Preparation of alkali particle intermediate

[0122] Mix calcium carbonate and vitamin D3 evenly in equal proportions.

[0123] Sodium bicarbonate, essence, aspartame, and povidone were sequentially added to the above mixture, and mixed for 15 minutes.

[0124] Pour the above mixed material into the fluidized drying bed.

[0125] 65% by weight of amb is dissolved in water to obtain a solid content of 10% amb solution.

[0126] Carry out one-step granulation, control the air inlet temperature at 75°C, control the material temperature at 35°C, and control the liquid inlet speed at 200ml / min. After spraying all the coating liquid within 3 hours, turn off the air inlet heating device and blow it with hot air. After 30 minutes, the intermediate product of alkali granules was obtained, which contained:

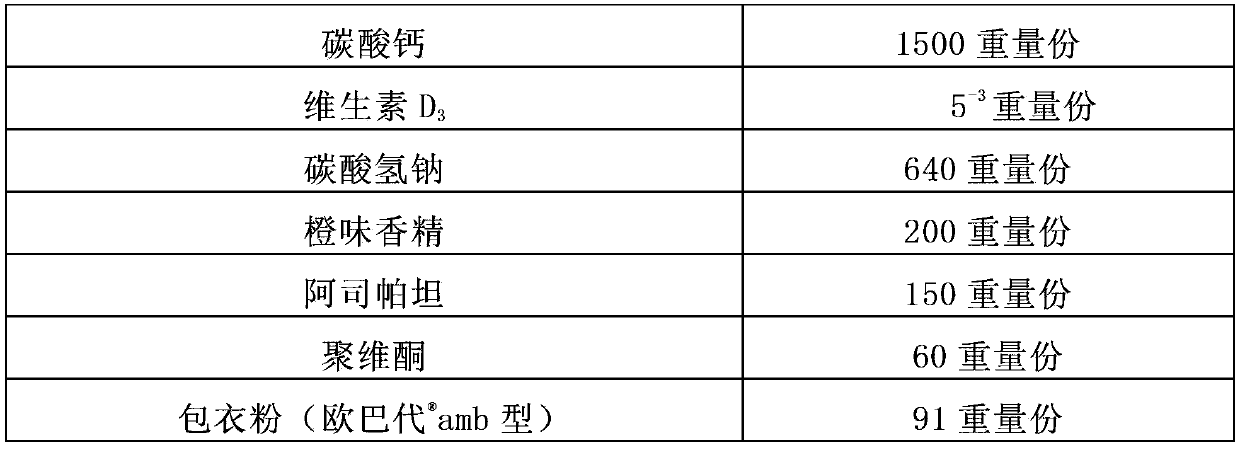

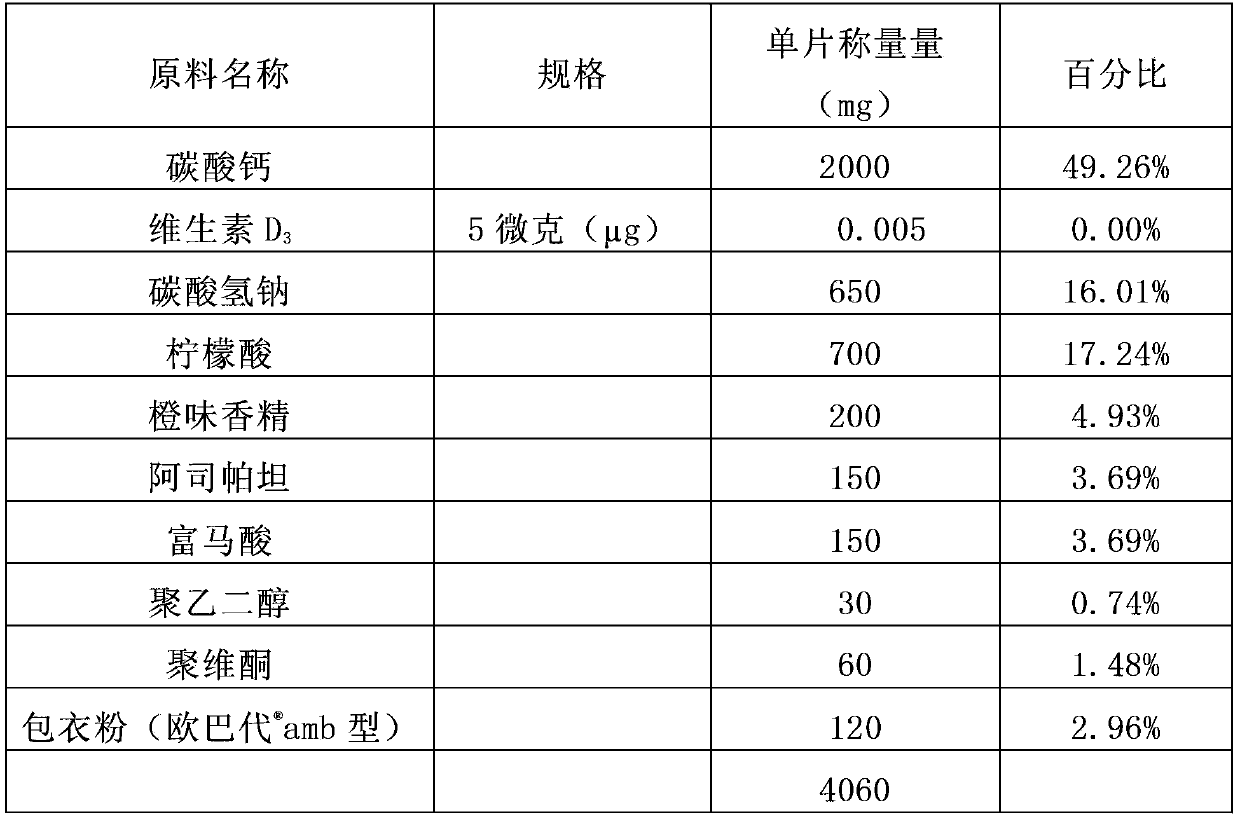

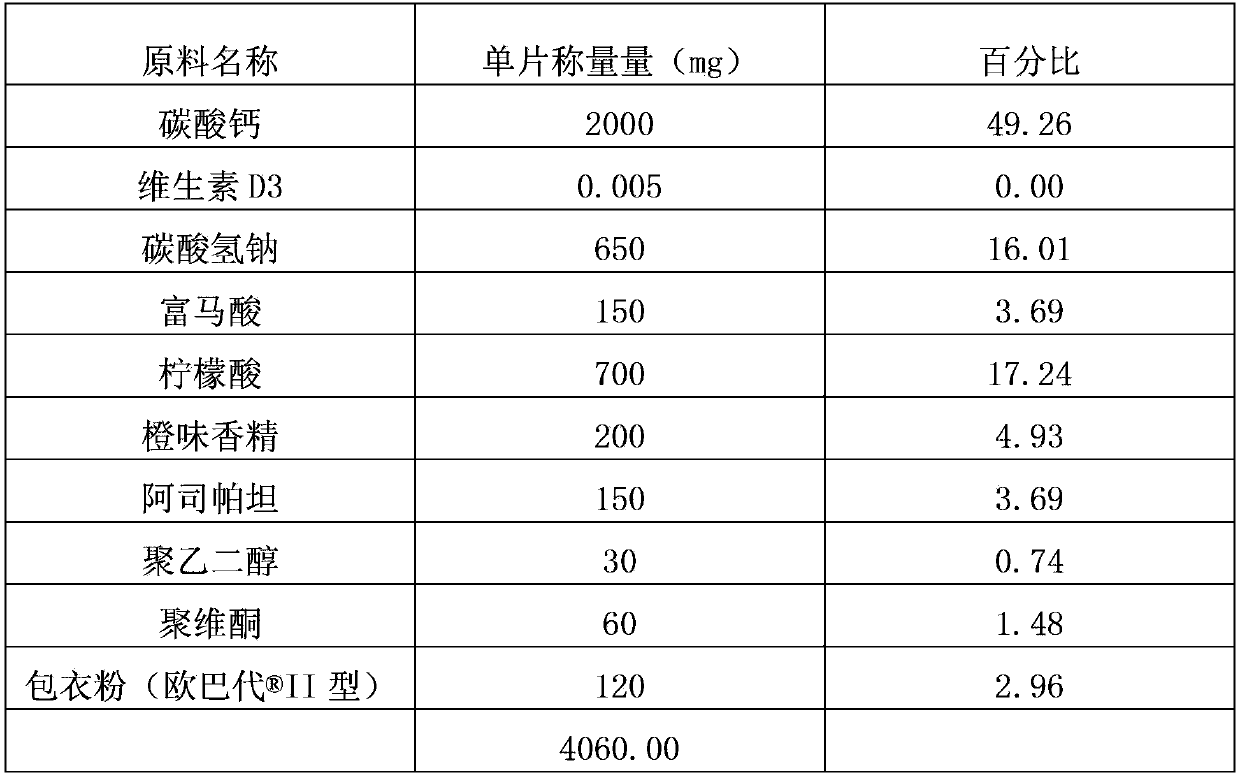

[0127]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com