Method for detecting target substance in to-be-detected sample based on fluorescent sensing analysis of aptamer probe

A nucleic acid aptamer, a technology in a sample, used in biochemical equipment and methods, and the determination/inspection of microorganisms, which can solve problems such as difficulty in returning to the initial state, fragile tertiary conformation, and low stability and repeated use times.

- Summary

- Abstract

- Description

- Claims

- Application Information

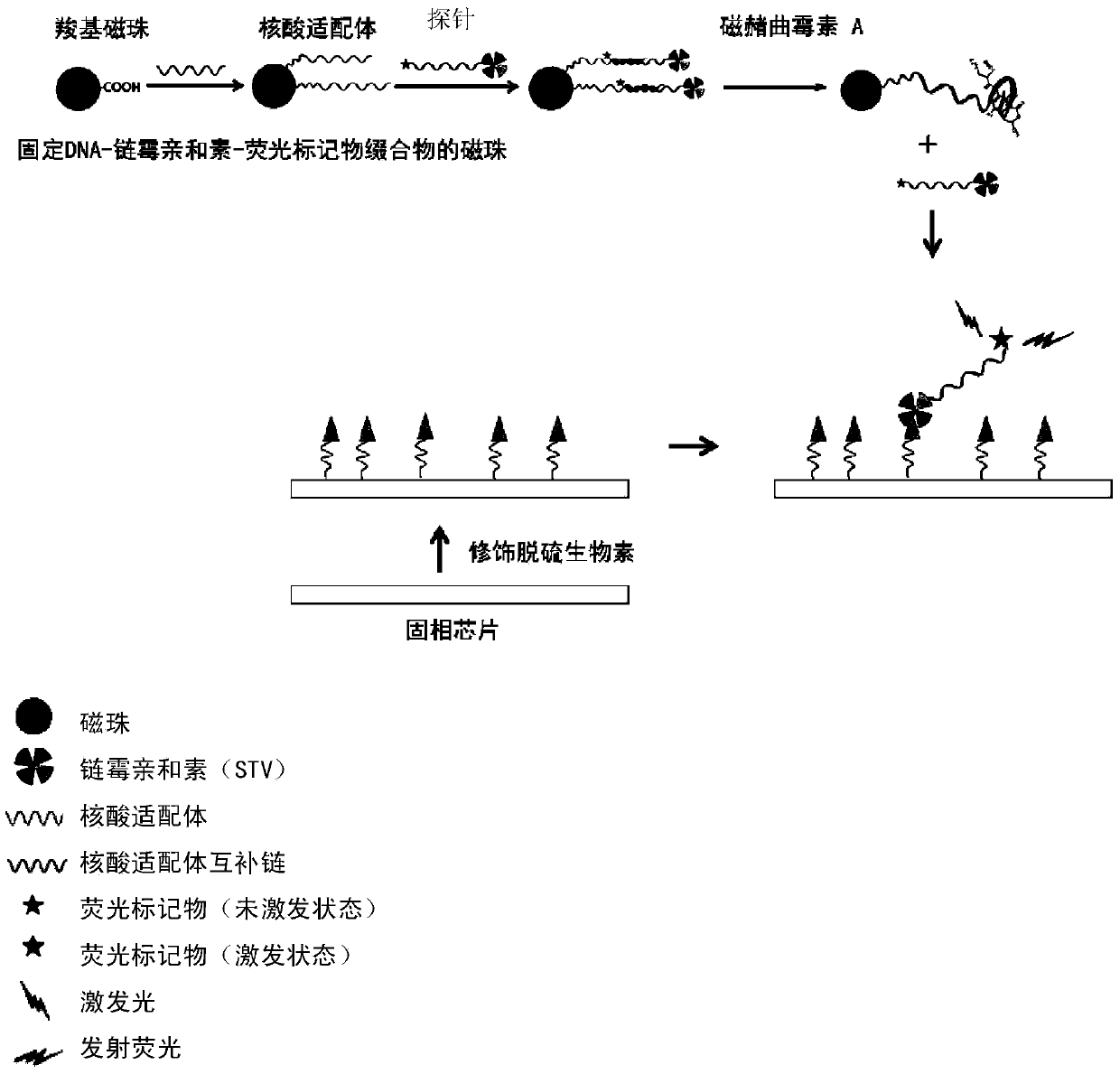

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

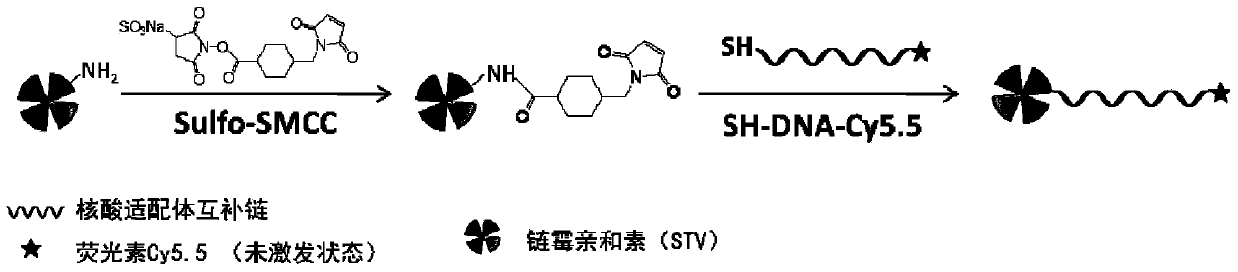

[0052] Embodiment 1, the preparation of kit

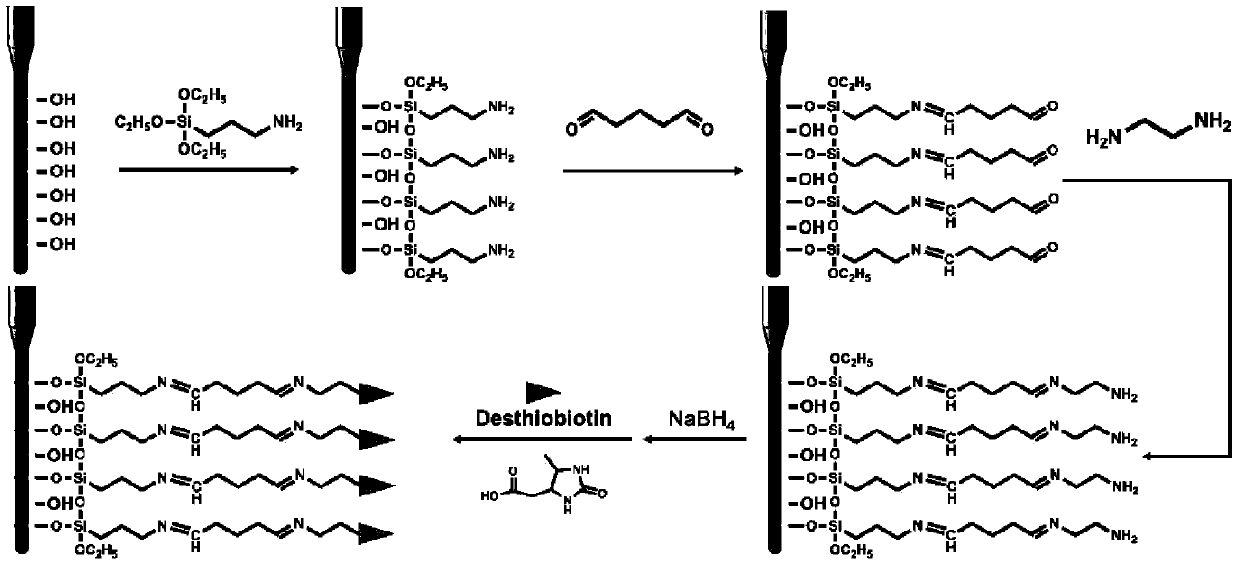

[0053] 1. Preparation of optical fiber surface modified with desthiobiotin

[0054] See flow chart figure 2 .

[0055] 1. Take the optical fiber and make its surface hydroxylated.

[0056] Specific methods: (1) Immerse the optical fiber (570 / 600 / 900, purchased from Nanjing Chunhui Technology Industrial Co., Ltd.) in piraha solution (98% concentrated H 2 SO 4 :H 2 o 2 =3:1, volume ratio) and reacted at 120°C for 1 h; (2) After step (1), take out the optical fiber, wash it with ultrapure water until the pH value is neutral, dry it with nitrogen at room temperature, and then place it in Store in a vacuum oven at 70°C for 1 hour.

[0057] 2. After completing step 1, take the optical fiber and modify its surface with APTS.

[0058] Specific methods: (1) After completing step 1, take the optical fiber and place it in the APTS solution for 1 hour of reaction; (2) After completing step (1), take out the optical fiber, rinse it wit...

Embodiment 2

[0087] Embodiment 2, detection ochratoxin A

[0088] Using DMF as solvent, prepare 1 mg / mL stock solution of ochratoxin A.

[0089] 1. Take the functional magnetic bead suspension (containing about 20 mg magnetic beads) of Example 1, wash it twice with PBS buffer containing 2 mg / mL BSA, and discard the supernatant.

[0090] 2. After completing step 1, take the magnetic beads, add ochratoxin A stock solution, and add PBS buffer solution containing 2 mg / mL BSA to make the total volume of the reaction system 350 μL, and mix for 15 minutes. The ochratoxin A stock solution is set with different addition amounts, so that the concentration of ochratoxin A at the initial moment of the reaction system is 6.4nM, 38.2nM, 95.4nM, 158.7nM, 222.6nM, 445.3nM, 635.0nM, 1269.6nM , 3174.9nM or 3710.0nM, each concentration set three replicates.

[0091] 3. After completing step 2, perform magnetic separation and collect the supernatant (solution to be tested).

[0092] 4. The operation proced...

Embodiment 3

[0095] Embodiment 3, the number of reusable times of the optical fiber prepared in step 1 of embodiment 1

[0096] Using DMF as solvent, prepare 1 mg / mL stock solution of ochratoxin A.

[0097] 1. Take the functional magnetic bead suspension (containing about 20 mg magnetic beads) of Example 1, wash it twice with PBS buffer containing 2 mg / mL BSA, and discard the supernatant.

[0098] 2. After completing step 1, take the magnetic beads, add ochratoxin A stock solution, and add PBS buffer solution containing 2 mg / mL BSA, so that the total volume of the reaction system is 350 μL (the initial moment of the reaction system is ochratoxin A The concentration is 3μM), mixed for 15min.

[0099] 3. After completing step 2, perform magnetic separation and collect the supernatant (solution to be tested).

[0100] 4. The operating procedure of the all-fiber evanescent wave biosensor: turn on the laser, and the excitation wavelength is 650nm; wash the optical fiber prepared in step 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com