Preparation method of ultrahigh-strength aluminum alloy material

An aluminum alloy material, ultra-high-strength technology, applied in the field of aluminum alloy, can solve the problems that do not involve natural aging, achieve the effects of reducing natural aging time, uniform structure, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Weigh 84.2kgAl, 12kgZn, 2.4kgMg, 1.0kgCu, 0.2kgZr, 0.1kgMn, 0.1kgNi and put them into the furnace for smelting, among which Cu is Al-50Cu master alloy, Ni is Al-20Ni master alloy, and the rest are pure metals , the smelting process is as follows: put the above-mentioned alloys including Al, Al-50Cu master alloy, and Al-Ni master alloy into the intermediate frequency induction furnace, and add electricity until the metal in the crucible melts, and the temperature of the melt rises to 720°C- Add Zr particles and pure Mn flakes at 740°C, stir fully and raise the melt temperature to 800°C-820°C, press pure Zn and pure Mg with a graphite pressure spoon after power off, stir well, and raise the melt temperature to 720°C-750°C; using refining agent and modifier (0.5% by weight) and C 2 Cl 6 The degassing agent modifies and refines the melt. After the treatment, the slag is removed from the melt, and then the melt is left to stand for 10min-15min, and the temperature of the me...

Embodiment 2

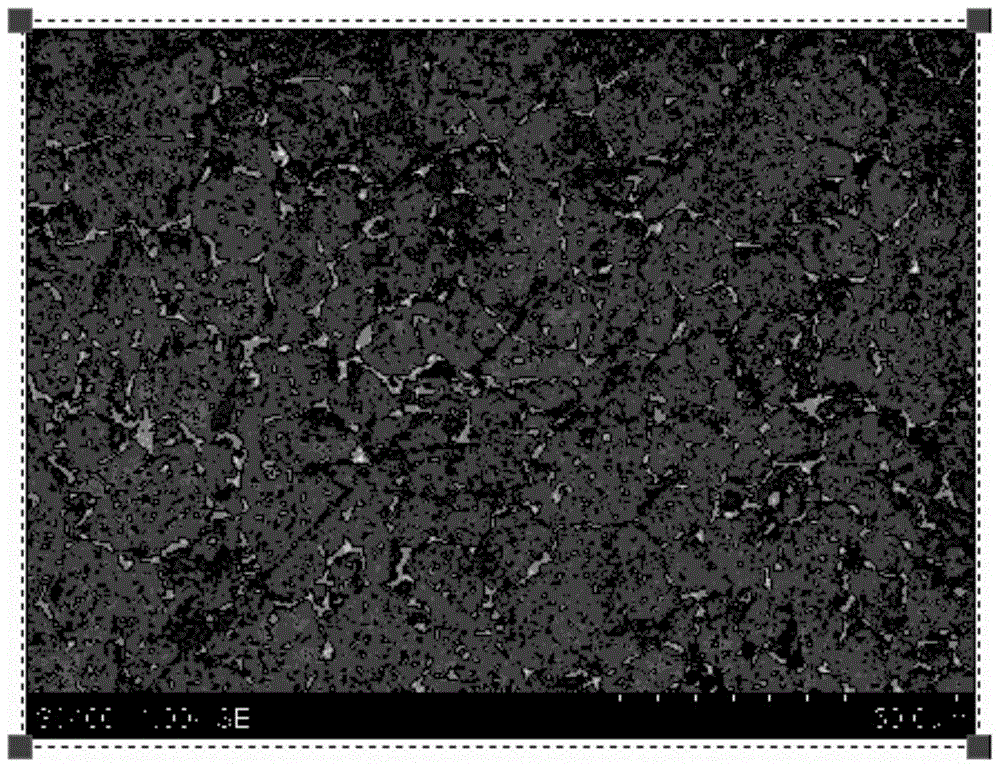

[0037] Weigh 79.9kgAl, 14kgZn, 3.2kgMg, 1.5kgCu, 0.5kgZr, 0.3kgMn, 0.6kg Ni respectively and put them into the furnace, where Cu is made of Al-50Cu master alloy, Ni is made of Al-20Ni master alloy, and the rest are all pure metals . According to the steps in Example 1, raw material smelting, billet forming, billet deformation, aluminum alloy solution treatment and artificial aging treatment were completed, wherein the artificial intervention natural aging treatment time was 360h and 480h respectively. Figure 6 Microstructure of artificially intervened natural aging state for 360h for spray deposition ultra-high strength aluminum alloy.

[0038] From Figure 6 It can be seen from the figure that there are a large number of GP regions in the artificially-intervened natural aging tissue of 360h, and MgZn 2 (η') phase, the appearance of this phase can make the properties of the alloy reach the peak. The mechanical properties of the alloys with the above two aging times were an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com