Chemical type deodorant for waste transfer station and preparation method thereof

A waste transfer station, deodorant technology, applied in chemical instruments and methods, botanical equipment and methods, deodorization, etc., can solve the problems of harsh living environment of microorganisms, inability of beneficial bacteria to survive effectively, and limited application scope, etc. The effect of long-term deodorization technology, the effect of improving comprehensive deodorization performance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

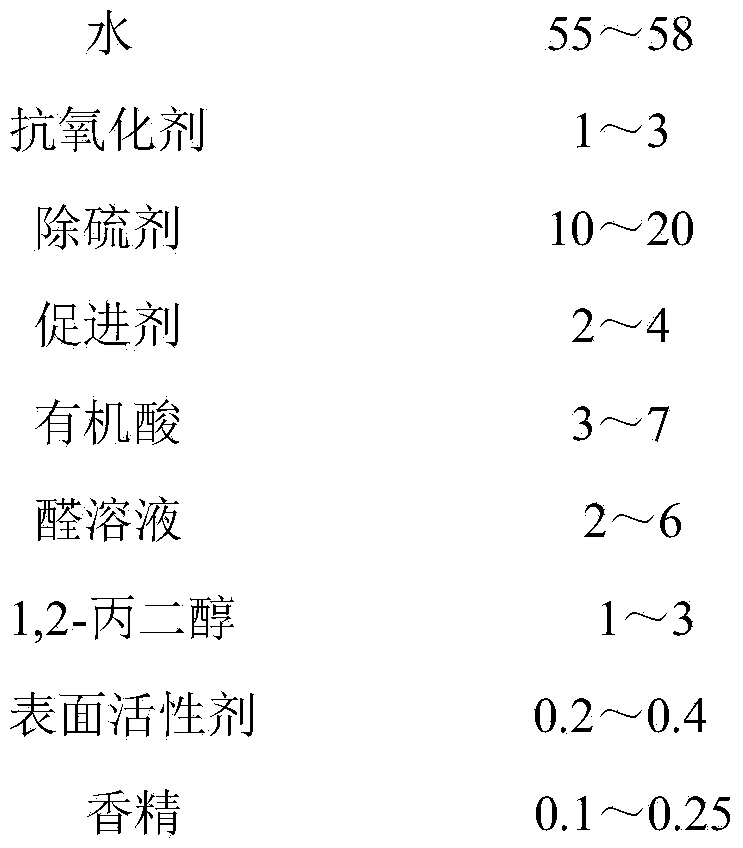

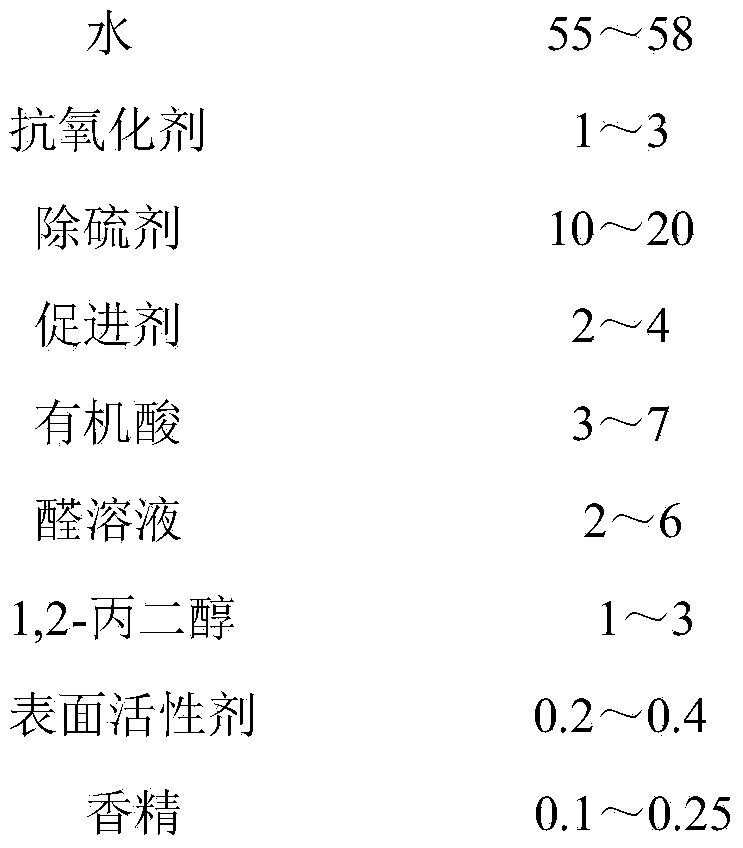

[0031] Example 1: An on-site deodorization test was carried out at a garbage transfer station in Nanjing. First, a pool with a severe rancid smell was selected, and the ability of the deodorant to remove the odor of hydrogen sulfide was focused on. The mass percentage of each component is: ascorbic acid 1%; ferrous sulfate 20%; copper sulfate 3%; citric acid 6%; glyoxal 1.6%; glutaraldehyde 1.4%; 1,2-propanediol 1%; 0.3% trimethylammonium bromide; 3-4 drops of essence; the remaining amount of water. The specific operation steps are as follows:

[0032] (1) Preparation of stock solution

[0033] In 39.6g of water, first add 1g of ascorbic acid, stir until completely dissolved to obtain a clear solution. Then add 36.6g FeSO in batches 4 ·7H 2 O, continue to stir, the solution turns light green. Then, under the condition of stirring, add 4.7g CuSO 4 ·5H 2 O, the solution turned bright green at this time. Continue to stir, and gradually add 6g of citric acid, the solution ...

Embodiment 2

[0041] Example 2: A pond with a severe irritating stench was selected at a certain garbage transfer station in Nanjing, and the ability of the deodorant to remove ammonia was mainly investigated. The mass percentage of each component is: ascorbic acid 1%; ferrous sulfate 10%; copper sulfate 2%; citric acid 3%; glyoxal 3%; glutaraldehyde 3%; 1,2-propylene glycol 3%; dodecane 0.2% trimethylammonium bromide; 3-4 drops of essence; the rest of water.

[0042] The implementation method of this embodiment includes the preparation of the stock solution of the deodorant, the dilution and spraying of the stock solution, and the test of the deodorant effect. Concrete operation method is with embodiment 1. SKY2000-NH 3 The data obtained by the new type pump-suction ammonia detector shows that the deodorant prepared according to this method not only deodorizes thoroughly, but also reduces the odor concentration to 0.016mg / m within 20 minutes after spraying. 3 Below, and the deodorizatio...

Embodiment 3

[0043] Example 3: A pool with both rancid and foul odors was selected at a garbage transfer station in Nanjing, and a comprehensive deodorization test was carried out on it. The mass percentage of each component is: ascorbic acid 2%, ferrous sulfate 18%, copper sulfate 2.5%, citric acid 4%, glyoxal 2.5%, glutaraldehyde 2.5%, 1,2-propanediol 2%, dodecane 0.4% trimethylammonium bromide, 3-4 drops of essence, and the rest of water.

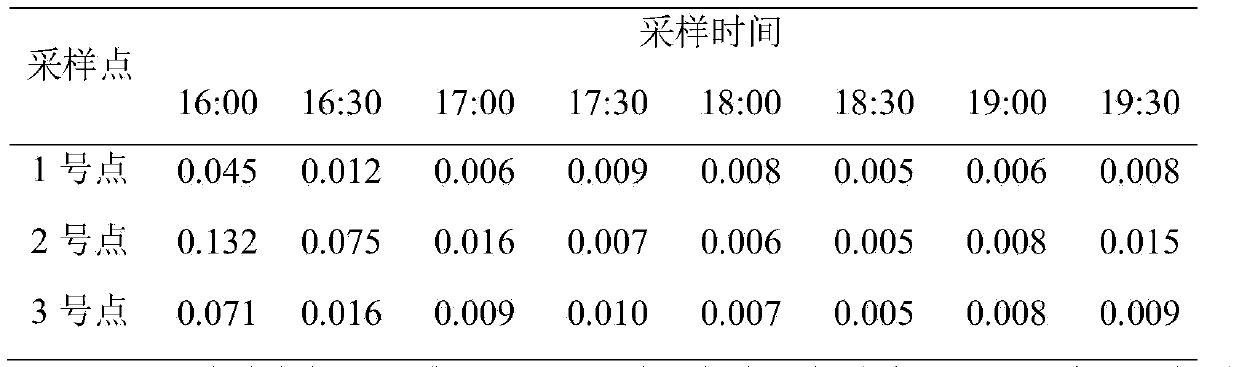

[0044] The implementation method of this embodiment includes the preparation of the stock solution of the deodorant, the dilution and spraying of the stock solution, and the test of the deodorizing effect. The specific operation method is the same as in Example 1. H on the scene 2 S, NH 3 Concentration testing, the results showed that the deodorant has a high-efficiency deodorizing effect, and the odor can be obviously reduced within 30 minutes after spraying; after one hour, the site basically does not smell the odor. The instrument test data sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com