Water-in-oil temperature controllable slow-release microcapsule and preparation method thereof

A technology of microcapsules and water-in-oil, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problem of losing the effect of sustained release, the effect of sustained release of microcapsules cannot be guaranteed, and the capsule shell of microcapsules cannot maintain the normal shape and other problems, to achieve the effect of dense shell structure, good sealing performance, and guaranteed properties of the capsule core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

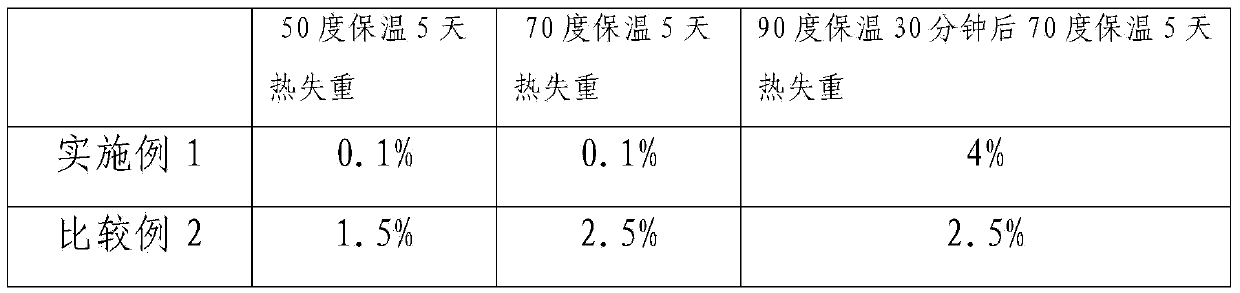

Embodiment 1

[0020] Use 9g of vinylidene chloride, 4.5g of acrylonitrile, 3.8g of methyl methacrylate, 0.7g of trifunctional acrylate, 1g of azobisisobutyronitrile, 9g of water-soluble flavor, 18g of melamine prepolymer, 5g of PVA, diisobutyronitrile Propylene 150g polypropylene 5g, sodium dodecylbenzene sulfonate 1.5g, span 800.3g, cetyl alcohol 1.0g, put into a 500ml three-necked flask, homogenize at 15000 rpm for 10 minutes under the homogenizer, connect to stir and Condensation and reflux device, the material is kept at 25°C for 8 hours, and after 65°C for 24 hours, it is filtered, the filter cake is rinsed twice with n-heptane, and then dried at 60°C to constant weight to obtain 35g of solid powder (particle size 10-50μm). The microcapsules have a slow-release effect after being heated to 90°C.

Embodiment 2

[0022] Select 13g of acrylonitrile, 3.8g of methyl methacrylate, 0.7g of trifunctional acrylate, 0.5g of methyl acrylate, 1g of azobisisobutyronitrile, 9g of ethylene glycol, 16g of melamine prepolymer, 5g of PVA, diisopropyl 150g of benzene, 5g of polypropylene, 1.2g of sodium dodecylbenzenesulfonate, 0.3g of Tween, and 1.0g of cetyl alcohol were put into a 500ml three-necked flask, homogenized at 15,000 rpm for 8 minutes with a homogenizer, and then stirred And condensing reflux device, the material is kept at 20°C for 8 hours, and after 65°C for 30 hours, it is filtered, the filter cake is rinsed with n-heptane for 3 times, and then dried at 60°C to constant weight to obtain 35g of solid powder (particle size 10-50μm), The microcapsules have a slow-release effect after being heated to 150°C.

Embodiment 3

[0024] Select acrylonitrile 3g, methyl methacrylate 14g, trifunctional acrylate 0.5g, methyl acrylate 0.5g, azobisisobutyronitrile 1g, water-soluble pesticide 9g, melamine prepolymer 18g, PVA 5g, diisopropyl 150g of benzene, 5g of polypropylene, 1.3g of sodium dodecylbenzenesulfonate, 800.3g of span, and 1.0g of cetyl alcohol were put into a 500ml three-necked flask, homogenized at 15,000 rpm for 8 minutes under a homogenizer, followed by stirring and Condensation and reflux device, the material is kept at 10°C for 8 hours, and at 65°C for 48 hours, then filtered, the filter cake is rinsed with n-heptane for 3 times, then dried at 60°C to constant weight to obtain 37g of solid powder (particle size 10-50μm), micro The capsule has a sustained release effect after being heated to 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com