Zirconium oxide-based porous composite material and preparation method thereof

A porous composite material and composite material technology are applied in the field of zirconia-based porous composite materials and their preparation, which can solve problems such as difficulty in preparing porous ceramics and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

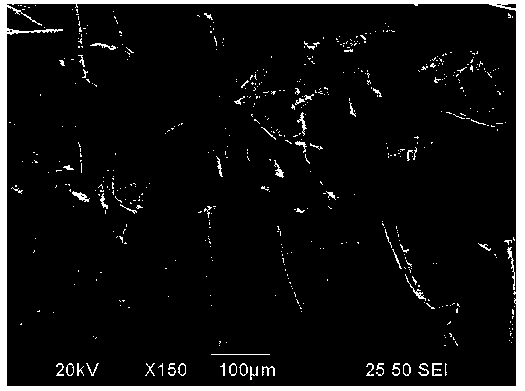

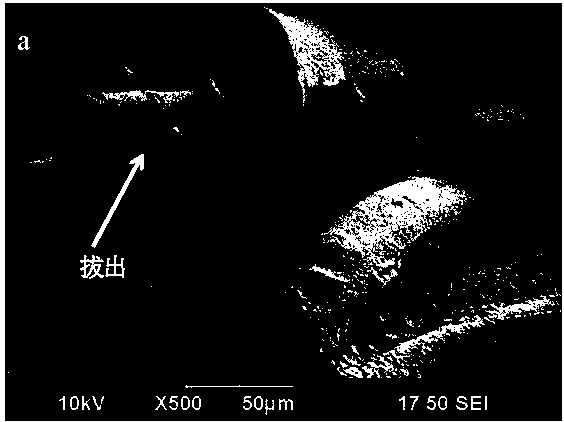

[0035] The invention relates to a method for preparing a zirconia-based heat-insulating, high-temperature-resistant and anti-oxidation porous composite material (using zirconia felt as a reinforcement fiber), which uses the original inorganic salt zirconium oxychloride (ZrOCl 2 ·8H 2 O) is the zirconia precursor. The zirconia precursor impregnation liquid is introduced into the reinforcement fiber (zirconia felt) skeleton by vacuum pressure impregnation process, impregnated, dried, and cracked twelve times in a cycle. Obtained by pressing and sintering (using zirconia felt as reinforcement fiber) zirconia-based porous composite material, the bulk density can be 2.93-3.32g / cm 3 , the open porosity is 41.1-49.8%, the compressive strength is 14.6-47.4MPa, and the thermal conductivity of the zirconia porous composite material is 0.58-0.91W / ( m·K). The invention creates a lightweight, heat-insulating, and high-temperature-resistant porous material and a preparation method thereof...

Embodiment 1

[0066] Dissolve 180g of zirconium oxychloride in 150ml of water and stir to dissolve it. Add 11.54g of yttrium nitrate hexahydrate and 7.85g of lanthanum nitrate hexahydrate and mix well, and add 1.13g of polyethylene glycol as a dispersant, and then add 285ml of dilute ammonia water (concentration: 2mol / L) dropwise. After the ammonia water was added dropwise, the solution was heated to evaporate part of the solvent to reduce the total volume of the mixed solution to 130ml, and cooled to room temperature to obtain a zirconia precursor emulsion. Then the zirconia precursor emulsion, ethanol and 5wt% concentration polyvinyl alcohol (PVA) solution were uniformly mixed according to the volume ratio of 100:80:1, and the room temperature viscosity of the slurry was controlled to 20-60mPa·s and the viscosity was measured with a rotational viscometer. Put the zirconia felt in the vacuum impregnation tank. When the impregnation tank is evacuated below 100Pa, suck the impregnation solut...

Embodiment 2

[0072] Other processes are the same as in Example 1, but sintered at 1500°C and kept for 2 hours, the bulk density of the zirconia felt / zirconia porous composite material obtained in this example is 3.18g / cm 3 , the open porosity is 44.1%, the thermal conductivity is 0.66-0.91W / (m·K) in the temperature range of 100-1200°C, the compressive strength is 19.8MPa, and the zirconia felt accounts for about 30wt% of the zirconia-based porous composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com