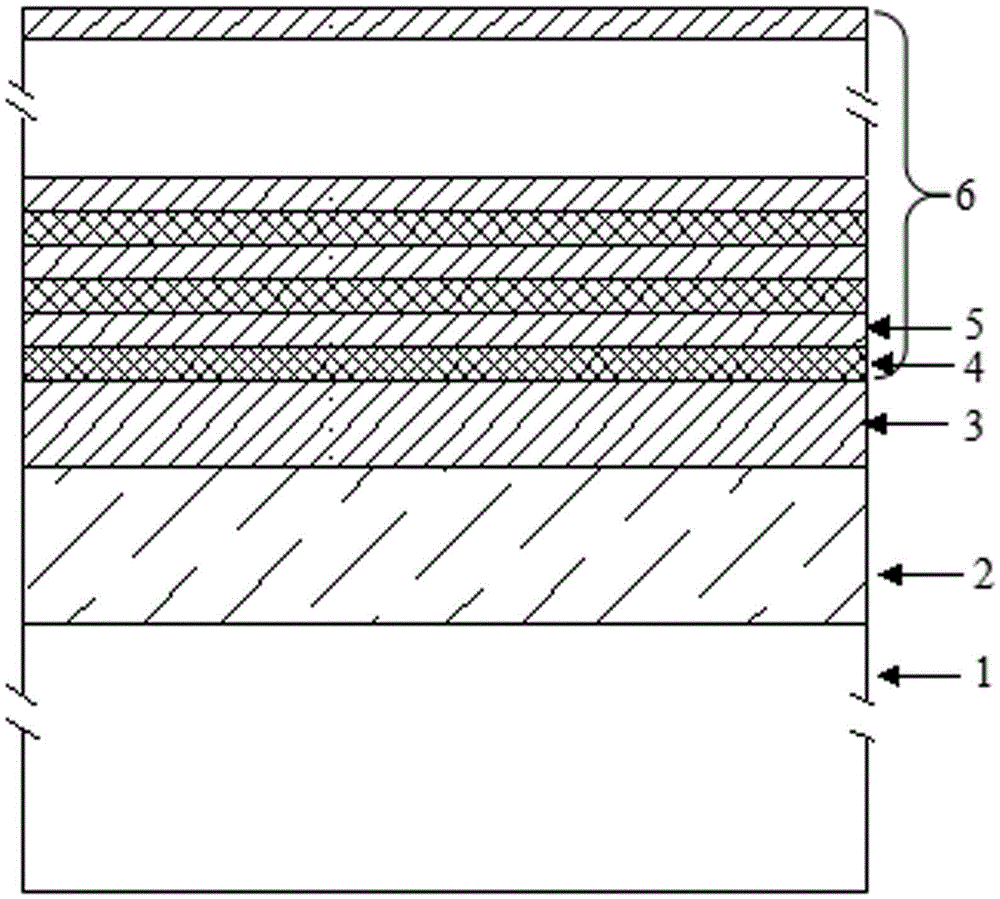

A kind of carbon/carbon composite material multi-layer coating and preparation method thereof

A carbon composite material, multi-layer coating technology, applied in the direction of layered products, etc., can solve the problems of complex exhaust gas treatment, complex process, high toxicity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Cut the carbon / carbon composite material into a block sample of 15×15×10mm, grind it with 400#-800# sandpaper, then ultrasonically use acetone for 20min, and dry it at 150°C for 1 hour before use.

[0027] 2) Prepare the SiC bottom layer by brushing method: the ratio of material powder is: Si powder 79%, C powder 13%, Al 2 o 3 8% powder, put the powder into ethanol solution and stir evenly to form a slurry, brush the slurry evenly on the surface of the C / C composite material, the thickness of the brush coating is 200μm, put it into a graphite crucible after drying, put In the vacuum furnace, the temperature was raised to 1800°C at a rate of 10°C / min, and the temperature was kept for 2 hours under the protection of argon. Then the temperature was lowered to 1200° C. at a rate of 10° C. / min, and then cooled to room temperature with the furnace to obtain a SiC bottom layer.

[0028] 3) Carbon with SiC underlayer / The carbon composite matrix was ultrasonically cleane...

Embodiment 2

[0034] 1) Cut the carbon / carbon composite material into a block sample of 15×15×10mm, grind it with 400#-800# sandpaper, then ultrasonically use acetone for 30min, and dry it at 150°C for 1.5 hours before use.

[0035] 2) Prepare the SiC bottom layer by brushing method: the ratio of material powder is: Si powder 75%, C powder 15%, Al 2 o 3 10% powder, put the powder into the ethanol solution and stir evenly to form a slurry, brush the slurry evenly on the surface of the C / C composite material, the thickness of the brush coating is 100 μm, put it into a graphite crucible after drying, and put In the vacuum furnace, the temperature was raised to 1700°C at a rate of 10°C / min, and the temperature was kept for 1.5 hours, under argon protection. Then the temperature was lowered to 1200° C. at a rate of 10° C. / min, and then cooled to room temperature with the furnace to obtain a SiC bottom layer.

[0036] 3) Carbon with SiC underlayer / The carbon composite matrix was ultrasonical...

Embodiment 3

[0042] 1) Cut the carbon / carbon composite material into a block sample of 15×15×10mm, grind it with 400#-800# sandpaper, then ultrasonically use acetone for 40min, and dry it at 200°C for 1 hour before use.

[0043] 2) Prepare the SiC bottom layer by spraying method: when the argon flow rate is 40L / min, the H 2 The flow rate is 6L / min, the spray distance is 250mm, the current is 550A, the voltage is 50V, the powder feeding rate is 50g / min, and the thickness of the sprayed Si coating is 400μm. Then the sprayed Si coating was heat-treated in vacuum at 1800 °C for 2 hours to obtain the SiC bottom layer.

[0044] 3) Carbon with SiC underlayer / The carbon composite matrix was ultrasonically cleaned with acetone for 40 minutes, dried and placed in a vacuum chamber for later use.

[0045] 4) Pump the vacuum to below 5×10 -3 Pa, the temperature is 200°C, filled with argon gas, the pressure is 1.0Pa, the bias voltage is 800V, and the ion source is used to test the carbon with SiC b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com