Catalyst used for preparation of bromomethane and CO through methane bromination-oxidation, and preparation method and application thereof

A methane bromide oxidation and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of precious metal Rh loss, activity reduction, high reaction temperature, etc., and achieve excellent anti-carbon deposition performance , good stability performance, the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: FePO 4 Preparation of dipping solution

[0036] Use deionized water as a solvent to prepare 1mol / L ferric nitrate solution and 1mol / L ammonium dihydrogen phosphate solution; then slowly add an equal volume of ammonium dihydrogen phosphate solution to nitric acid In the iron solution, the mixed solution was stirred for 12 hours to obtain pink FePO 4 The impregnating solution is put into a volumetric flask for later use.

Embodiment 2

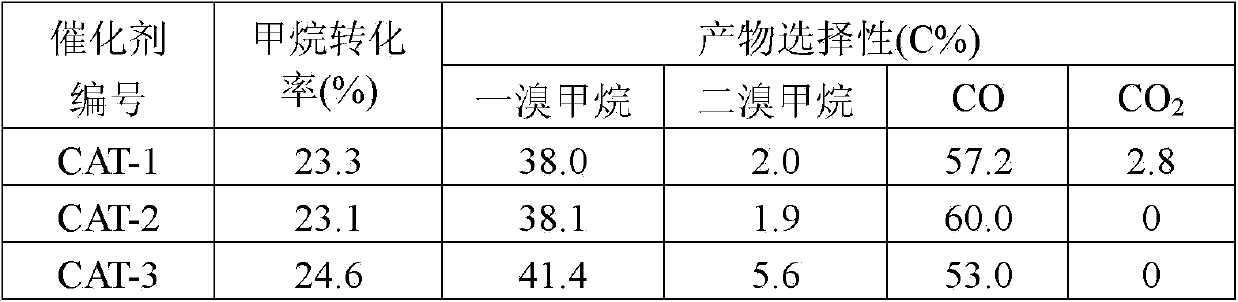

[0037] Embodiment 2: the preparation of non-precalcined catalyst CAT-1

[0038] Weigh 8.0 grams of TiC-SiC carrier (Ti weight content is about 10%), add 11.8mL of FePO prepared in Example 1 4 The impregnated solution was soaked for 6 hours, then dried in an oven at 90°C for 12 hours, and then transferred to a muffle furnace for 10 hours in an air atmosphere at 400°C. The prepared catalyst was designated as CAT-1. Wherein, the weight content of the main active component is 10% according to the calculation of feeding. Its specific surface area is 500m2 measured on the American Kangta Autosorb-1 physical adsorption instrument. 2 / g.

Embodiment 3~4

[0039] Embodiment 3~4: the preparation of catalyst CAT-2 and CAT-3 without precalcining

[0040] Same as the procedure of Example 2, just change the roasting temperature to 600 DEG C and 800 DEG C respectively, thus make catalyst CAT-2 and CAT-3, record its specific surface area on the U.S. Quanta Autosorb-1 physical adsorption instrument 350m respectively 2 / g and 130m 2 / g. Wherein, the weight content of the main active component is 10% according to the calculation of feeding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com