A method for solidification of fine grains by low-frequency pulsed magnetic field using electromagnetic force-induced melt oscillation

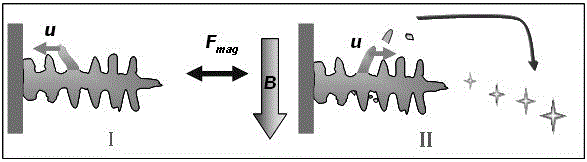

A low-frequency pulse and electromagnetic force technology, used in the field of low-frequency pulse magnetic field solidification of fine crystals, can solve the problems of high equipment cost, easy blockage of nozzles, and difficulty in floating of inclusions, reducing power consumption, obvious skin effect, and avoiding skin effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

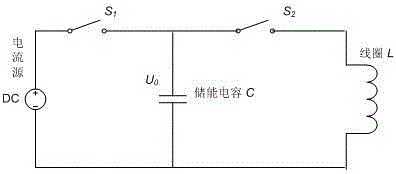

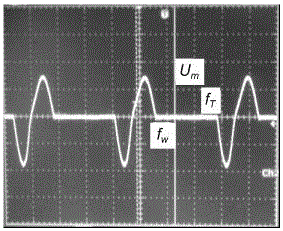

Embodiment 1

[0034] The Sn-20%Pb alloy was selected for the experiment, and the non-magnetic austenitic stainless steel crucible was selected as the mold. During the experiment, the Sn-20%Pb alloy ingot was remelted in a resistance furnace, and the wire mesh was placed in the melt. Insulate at 800ºC for 30 minutes, then pour into a graphite crucible with an inner diameter of about 40 mm and a height of about 100 mm. During the experiment, the magnetic field strength at the center of the fixed mold was 0.07T, and the spiral, rotary, and traveling wave electromagnetic stirring and low-frequency pulsed magnetic fields were applied respectively. The parameters of the low-frequency pulsed magnetic field are: the pulse discharge frequency is 1-10Hz, the pulse waveform frequency is 10-50Hz, and the pulse discharge voltage is 500v. After the solidification experiment, at the same position of the melt sample, use a metallographic microscope to observe the microstructure of the sample, as shown in ...

Embodiment 2

[0040] 304 austenitic stainless steel no longer undergoes δ→γ phase transformation during solidification. During the grain growth process, there is no phase transformation that hinders the columnar crystals, resulting in relatively developed columnar crystals and a low proportion of equiaxed crystals. In addition, vibration marks will be formed on the surface of 304 austenitic stainless steel during the continuous casting process. In the subsequent treatment, it needs to be removed after processing, which significantly affects the yield of the product.

[0041] During the implementation, for the 160*160mm billet continuous casting machine, the pulse excitation coil is placed between the No. 1 and No. 2 sections of the secondary cooling zone, and the casting billet is placed in the middle of the coil. The size of the coil is: outer diameter 400mm, inner diameter 280mm, height 500mm, insulation between coils. The coil is made of copper material. Since the Joule heat will be gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com