Urethane foam sheet, cushion material, and method for producing urethane foam sheet

A technology of foamed polyurethane and cushioning materials, which is applied in the direction of chemical instruments and methods, types of packaging items, and special packaging items, etc. Hardness and other problems, to achieve the effect of shrinkage suppression, high impact absorption, and small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

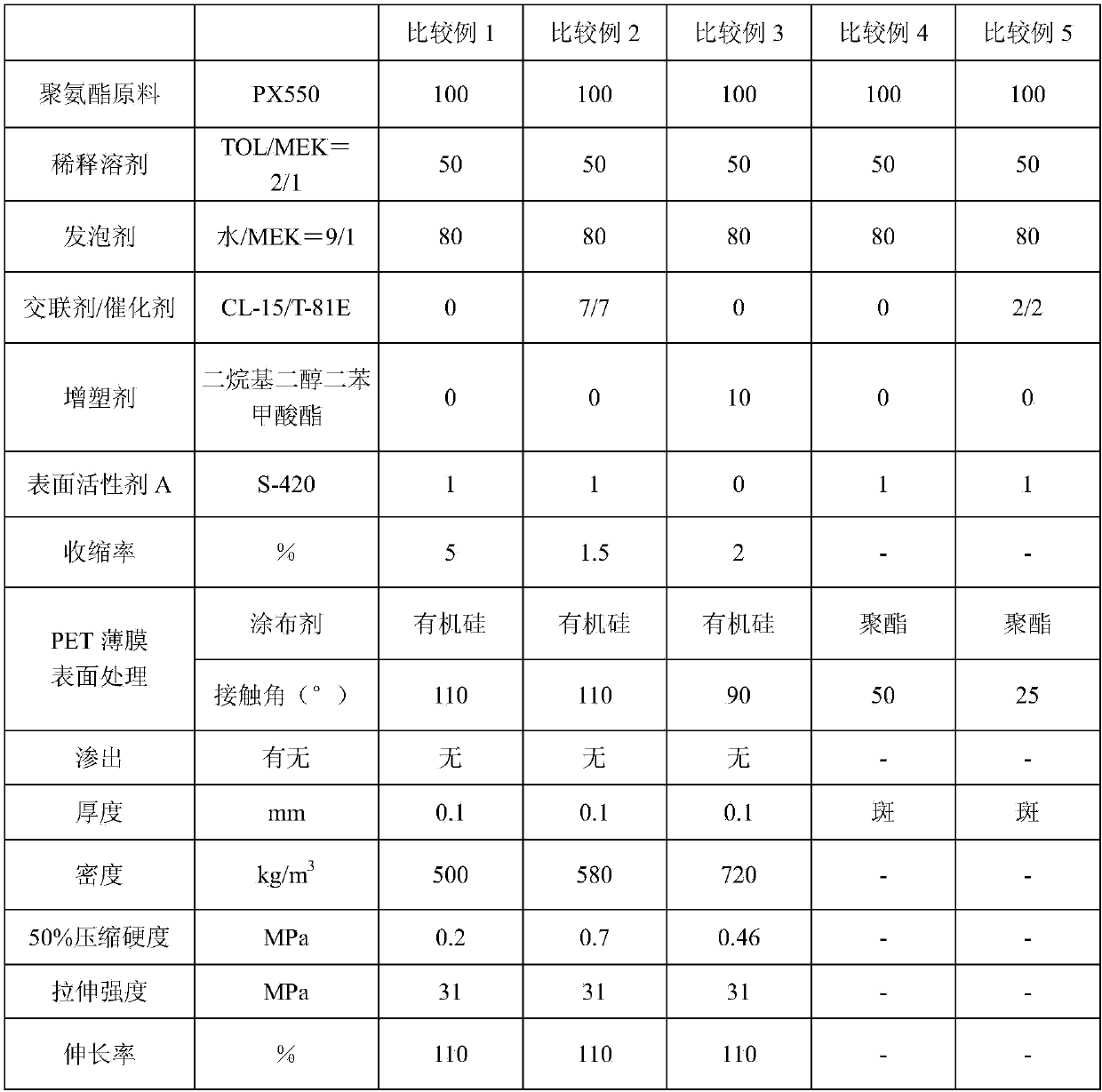

Embodiment 1

[0070] 100 parts of polyurethane resin solution (Zeltex PX550 manufactured by DIC Corporation), 50 parts of diluting solvent (toluene / 2-butanone=2 / 1), foaming agent (water / 2-butanone=9 / 1 ) and 1 part of perfluoroalkyl ethylene oxide adduct (AGC SEIMI CHEMICAL Co., Ltd., SURFLON S-420) as a surfactant were fully stirred and adjusted to 25°C. The adjusted solution was further stirred for 5 minutes with a mixer / defoamer, and then this solution was applied to one surface with a thickness of 0.025mm for 3 minutes. Evenly coated on the PET film with an adhesive layer on the surface, thus obtaining a thickness of 0.1mm and a density of 500kg / m 3 Polyurethane Foam Polyurethane Sheet. The shrinkage rate of this foamed polyurethane sheet was 0%.

Embodiment 2

[0072] Add 100 parts of polyurethane resin solution (ゾルテッックス PX550 manufactured by DIC Co., Ltd.), 50 parts of diluting solvent (toluene / 2-butanone=2 / 1), foaming agent (water / 2-butanone=9 / 1) ) 80 parts, perfluoroalkyl ethylene oxide adduct as a surfactant (SURFLON S-420 manufactured by AGC SEIMI CHEMICAL Co., Ltd.) 1 part, crosslinking agent and catalyst (crosslinking agent: hexamethylene Diisocyanate prepolymer, hexamethylene diisocyanate, catalyst solution: ethyl acetate / 2-butanone solution containing less than 1% organotin catalyst (dibutyltin dilaurate), 1 part each, stir well and adjusted to 25°C. The adjusted solution was further stirred for 5 minutes with a mixer / defoamer, and then the solution was applied to one surface with a thickness of 0.025 mm. After 3 minutes, the polyester coating with a contact angle of 75°, and one surface on the other side Uniform coating on the PET film substrate with adhesive layer, thus obtaining a thickness of 0.1mm and a density of 510k...

Embodiment 3

[0074] 100 parts of polyurethane resin solution (Zeltex PX550 manufactured by DIC Corporation), 50 parts of diluting solvent (toluene / 2-butanone=2 / 1), foaming agent (water / 2-butanone=9 / 1 ) and 1 part of perfluoroalkyl ethylene oxide adduct (AGC SEIMI CHEMICAL Co., Ltd., Surflon S-420) as a surfactant were fully stirred and adjusted to 25°C. The adjusted solution was further stirred for 5 minutes with a stirrer / defoamer, and then the solution was applied to one surface with a thickness of 0.025mm for 3 minutes. The polyester coating with a contact angle of 57° and the other side Evenly coated on the PET film substrate with an adhesive layer on the surface, thus obtaining a thickness of 0.01mm and a density of 680kg / m 3 Polyurethane Foam Polyurethane Sheet. The shrinkage rate of this foamed polyurethane sheet was 0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com