Modified wollastonite for polyvinyl chloride (PVC) cable sheath material capable of resisting 105 DEG C and preparation method of modified wollastonite

A polyvinyl chloride cable and wollastonite technology, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve problems such as poor compatibility and difficult polymer base material dispersion, and improve filling performance , Improve tensile strength, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

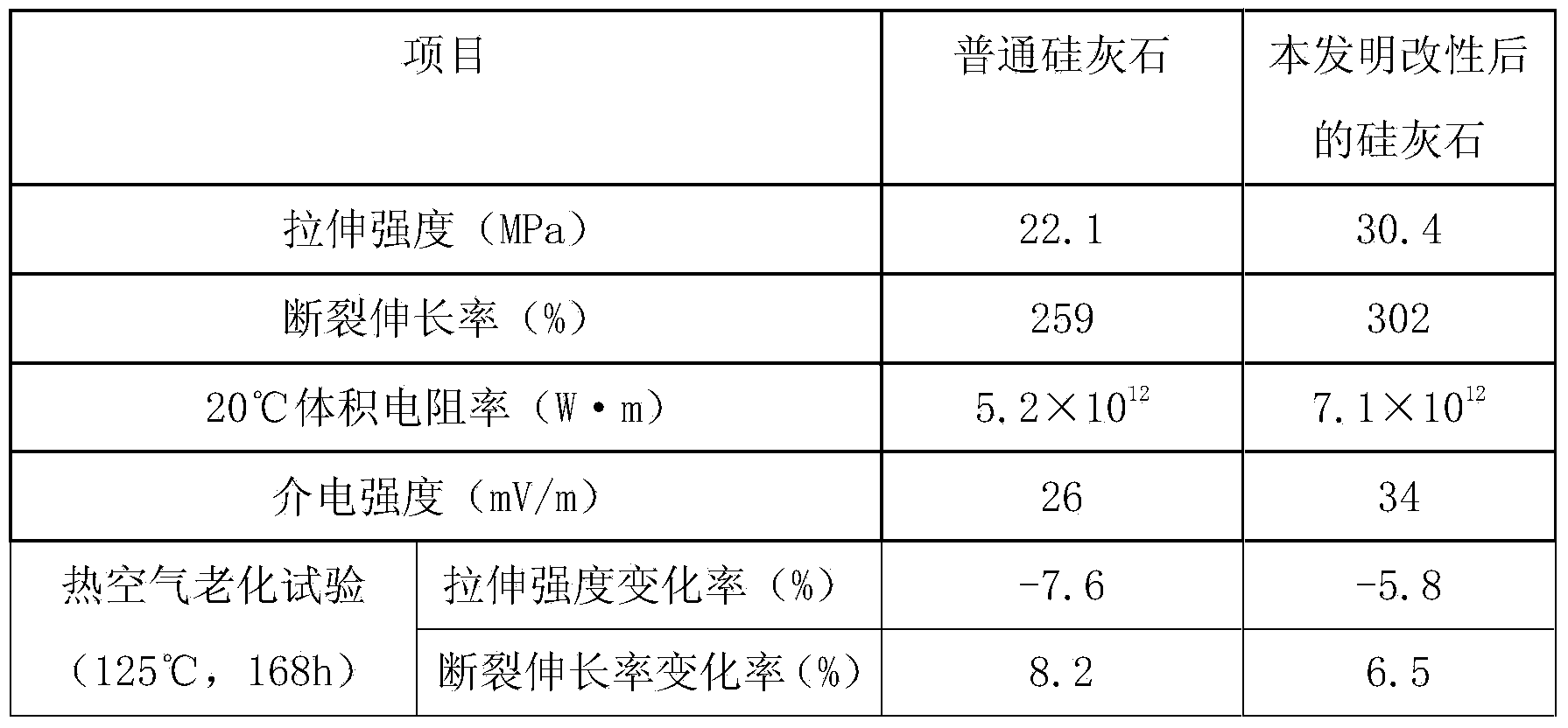

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A modified wollastonite for 105°C resistant polyvinyl chloride cable sheathing material, made of the following raw materials in weight (kg): wollastonite 50, polyε-caprolactone 15, aluminum dihydrogen tripolyphosphate 8 , Cetyl oil 4, Sorbitan monooleate 1.5, Polydiphenylsilaboroxane 2.5, Zinc stannate 4, Natural zeolite powder 8, Nano-tungsten carbide 6, Dibromotriphenyl antimony 3, Dilauryl Dibutyl tin acid 1.5, epoxy butyl oleate 8, bisphenol A polyoxyethylene ether 3, ethyl p-aminobenzoate 2, additive 4;

[0011] The auxiliary agent is mixed by the following weight (kg) raw materials: 2-(2H-benzotriazol-2-yl) p-cresol 2.5, zinc isooctanoate 0.7, bis(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite 1.5, tert-butylhydroquinone 2, barium fluoride 4, p-methoxybenzoyl chloride 2.5, tantalum disulfide 5, vinyl ferrocene 2, glycerol trilaurate Ester 2, bis-ethylhexyloxyphenol methoxyphenyl triazine 1.5.

[0012] The preparation method of modified wollastonite for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com