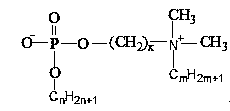

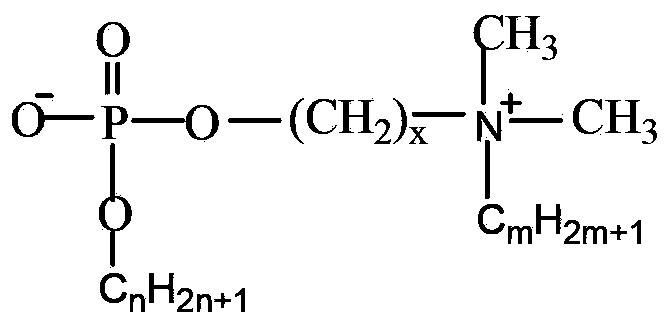

Negative-positive double-ion surfactant and preparation method thereof

A gemini surface, cationic technology, applied in the preparation of anion-cation type gemini surfactants, in the field of anion-cation type gemini surfactants, to achieve the effect of mild reaction conditions and convenient preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Accurately weigh 0.010 mol of phosphorus oxychloride in a dry Erlenmeyer flask, cool down to 0°C, add 0.005 mol of ethylene glycol dropwise, complete the dropwise addition in 30 minutes, and stir at room temperature for 10 minutes to prepare cyclovinyloxychlorophosphate. Use a dropping funnel to add a certain amount of n-octanol into the reactor at a rate of 1ml / min to 20ml / min, raise the temperature to 50°C-60°C, and react for a period of time to prepare the required intermediate. After removing the solvent by evaporation, the intermediate crude product and 0.030mol of tetradecyl dimethyl tertiary amine were reacted in absolute ethanol at 70°C-80°C for 40h to obtain the target product, and the solvent was removed by evaporation. recrystallized in a mixed solvent, and the separated product was placed in a vacuum oven to obtain a white powdery solid anion-cation type gemini surfactant.

Embodiment 2

[0047] Accurately weigh 0.010 mol of phosphorus oxychloride in a dry Erlenmeyer flask, cool down to 0°C, add 0.005 mol of 1,3-propanediol dropwise, complete the dropwise addition in 30 minutes, and stir at room temperature for 10 minutes to prepare cyclopropenyloxychlorophosphate. Use a dropping funnel to add a certain amount of benzene solution of dodecyl alcohol to the reactor at a rate of 1ml / min to 20ml / min. After the dropwise addition, the reaction temperature is raised to 50°C, and the required intermediate is prepared after 2 hours of reaction. After removing the solvent by evaporation, the intermediate crude product and 0.020mol of dodecyl dimethyl tertiary amine were reacted in absolute ethanol at 75°C for 48h to obtain the target product, and the solvent was removed by evaporation. In a mixed solvent of acetone and ethyl acetate Recrystallize in medium, and place the separated product in a vacuum oven to obtain a white powdery solid anion-cation type gemini surfactant...

Embodiment 3

[0049] Accurately weigh 0.010 mol of phosphorus oxychloride in a dry Erlenmeyer flask, cool down to 2°C, add 0.005 mol of 1,4-butanediol dropwise, complete the dropwise addition in 30 minutes, and stir at room temperature for 10 minutes to produce cyclobutenyloxychloride Phosphate. Add a certain amount of myristyl alcohol into the reactor, raise the temperature to 55°C, and react for 3 hours to prepare the required intermediate. After evaporating to remove the solvent, the intermediate crude product and 0.040mol of hexadecyldimethyl tertiary amine were reacted for 50h in absolute ethanol at 75°C to obtain the target product, and the solvent was removed by evaporation. In a mixed solvent of acetone and ethyl acetate Recrystallize in medium, and place the separated product in a vacuum oven to obtain a white powdery solid anion-cation type gemini surfactant.

[0050] When in use, according to the conditions of the well, select this type of surfactant and prepare it into a 0.05%-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com