Graphene oxide-cadmium telluride/cadmium sulfide nano composite material and preparation method thereof

A nanocomposite material and composite material technology, applied in the field of graphene oxide-cadmium telluride/cadmium sulfide nanocomposite material and its preparation, can solve problems such as poor stability and limited research, and achieve high fluorescence intensity and high fluorescence stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of NaHTe solution: add 0.75mmol NaBH 4 Add 0.375mmol Te powder to 12ml of double-distilled water, and react in an oil bath at 60°C for 30-60min. The resulting solution is filtered through a 0.22μm filter membrane to filter out the precipitate produced by the reaction to obtain a pure NaHTe solution.

[0029] (2) MPA modified Cd 2+ Preparation of precursor solution: 0.25mmol CdCl 2 ·2.5H 2 O, 52μL (0.6mmol) MPA was dissolved in 200mL double-distilled water, and the pH was adjusted to 8.5 with 1M NaOH, and nitrogen was blown for 30min under stirring to obtain MPA stabilizer modified Cd 2+ Precursor fluid.

[0030] (3) Preparation of CdTe quantum dots: Take 4ml of newly prepared NaHTe and add it to the Cd obtained in step (2) 2+ In the precursor solution, the CdTe quantum dot solution was obtained by refluxing with nitrogen at 100°C for 60 minutes. The solution was concentrated to 1 / 4 of the original volume. Isopropanol was added dropwise and centrifuged to obtain...

Embodiment 2

[0032] (1) Preparation of CdS cladding solution: add 0.25mmol CdCl 2 ·2.5H 2 O, 0.25mmol TAA and 1.2mmol MPA were dissolved in 200mL of double-distilled water, adjusted to pH 8.5 with 1M NaOH, and stirred with nitrogen for 30min to obtain a CdS cladding solution. Among them, Cd in CdS cladding solution 2+ : Stabilizer: S 2- The molar concentration ratio is 1:4.8:1.

[0033] (2) Preparation of CdTe / CdS core-shell quantum dots: Add the CdTe obtained in Example 1 to the CdS cladding solution, and reflux with nitrogen at 100°C for 120 minutes to obtain a CdTe / CdS core-shell quantum dot solution, and concentrate it To 1 / 4 of the original volume, add isopropanol dropwise and centrifuge to obtain a precipitate, and re-dissolve the obtained precipitate in a certain volume of double-distilled water for later use.

[0034] (3) figure 1 (a) shows the TEM picture of the obtained water-soluble CdTe / CdS core-shell quantum dots. It can be seen from the figure that the quantum dots are uniform in...

Embodiment 3

[0037] (1) 0.2g of GO and 0.2g of EDC·HCl were added to 20mL of DMSO for 3h ultrasonic reaction to activate the carboxyl groups on the graphene oxide.

[0038] (2) Add 0.3 g of PEI to the above system, and ultrasonically react for 24 hours.

[0039] (3) PEI-GO can be obtained by removing unreacted impurities in the system by dialysis.

[0040] (4) figure 1 (b) is a transmission electron microscope picture of PEI-GO. From the picture (b), it can be seen that the surface of GO is evenly coated with a layer of PEI, indicating that PEI can be well connected to the surface of graphene oxide through covalent bonds.

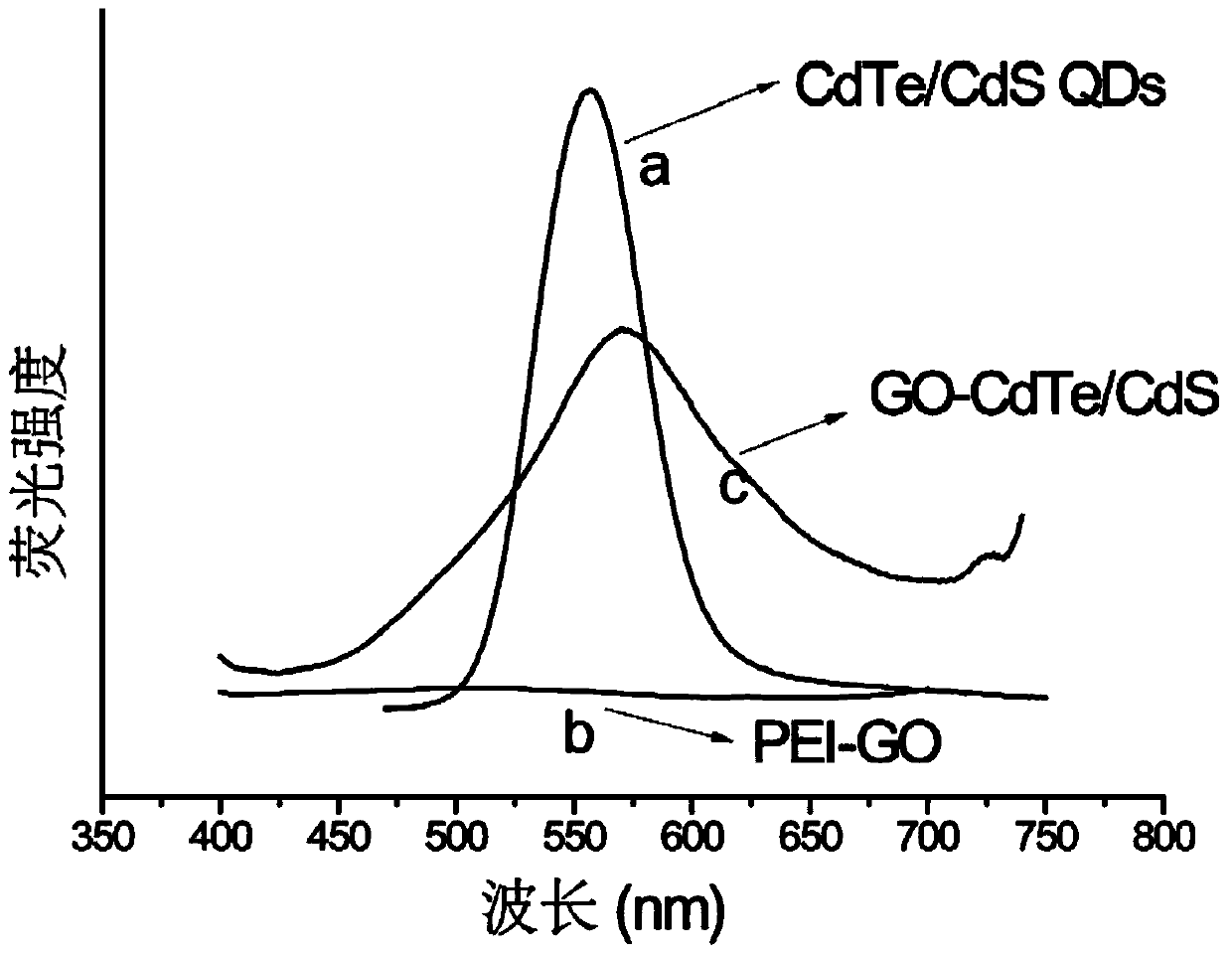

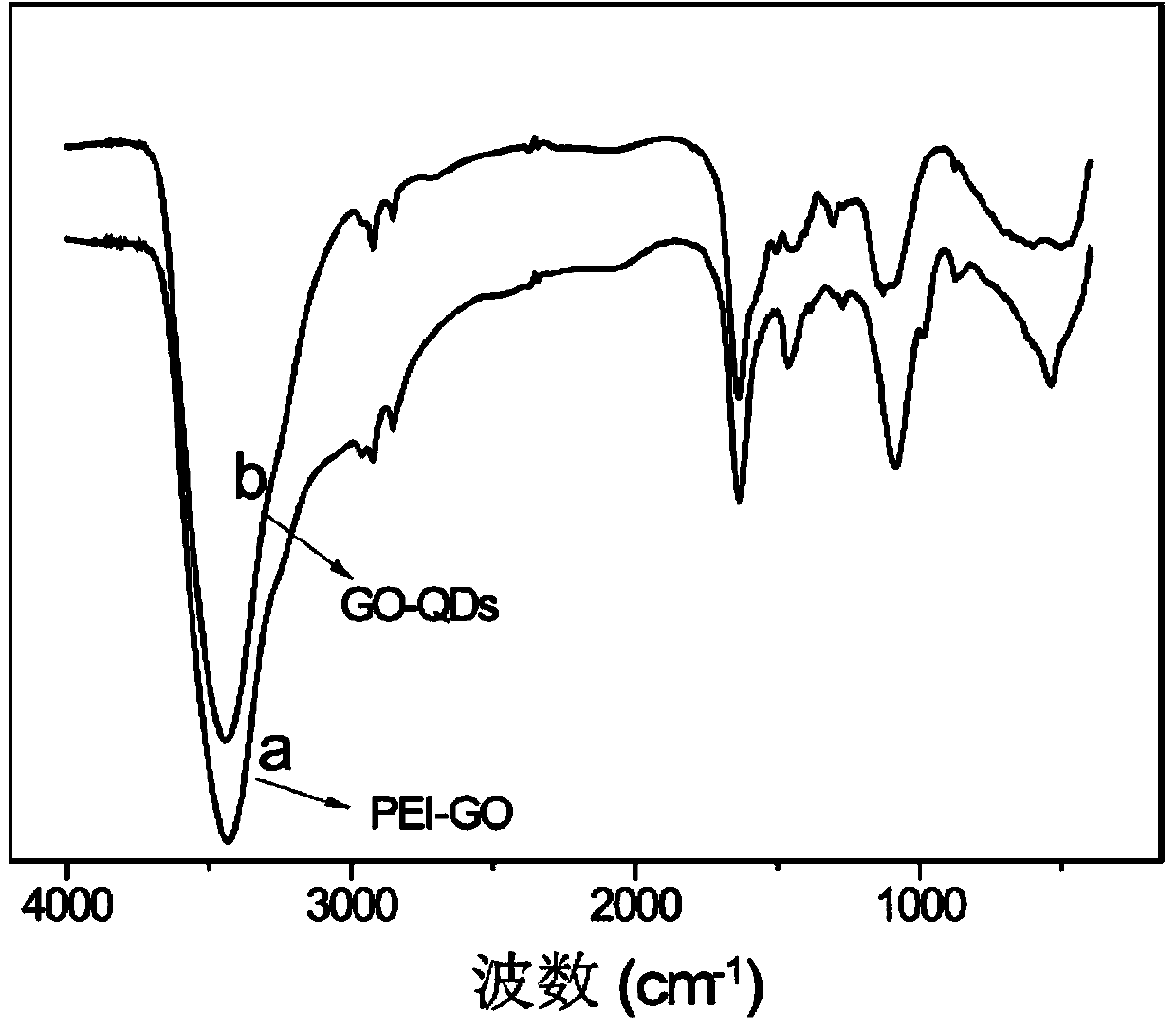

[0041] (5) image 3 -a is the infrared spectrum of PEI-GO. It can be seen from the figure that 2854 and 2917 are PEI-CH 2 -The characteristic absorption peak, 1448 is the characteristic absorption peak of the amide bond -CO-NH-.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com