Activated stranded wire welding wire for increasing penetration depth

A technology of stranded welding wire and welding wire, which is applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems that the wire feeding performance is not as good as that of solid core welding wire, the spatter of solid core welding wire is large, and the cost of flux cored welding wire is high. Achieve the effect of not easy to unfused welding defects, suitable for high current welding, and overcome the large investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Choose copper-free welding wire sold in 7 stock markets, with a diameter of 0.6mm and a model of ER50-6.

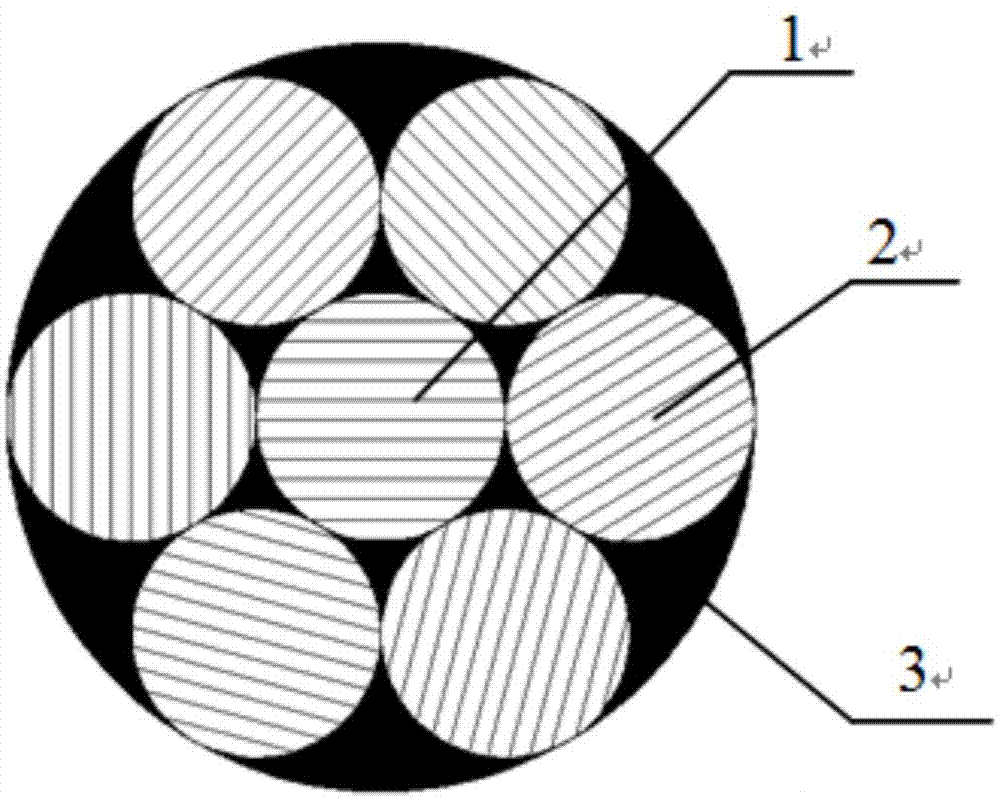

[0040] (2) One strand of solid-core welding wire is used as the central wire, and the rest of the welding wire is used as the peripheral wire, and the existing stranding machine is used to twist into a multi-strand wire blank.

[0041] (3) The active agent is prepared according to the following mass percentage, 55% SiO 2 , 15%TiO 2 , 10%Cr 2 o 3 , 6% NaF, 10% LiF, 3% potassium fluozirconate, 0.5% sodium stearate, 0.5% yttrium oxide.

[0042] Mix the above components in a conventional powder mixer for 15 minutes according to the formula, grind the mixed powder with a ball mill, and pass through a 460-mesh sieve (with a diameter not exceeding 0.03mm) to obtain the active agent powder.

[0043] (4) the multi-strand wire welding wire blank that step (2) is made carries out boronization treatment according to existing conventional technology, and its surface adh...

Embodiment 2

[0049] (1) Select the copper-plated welding wire sold in 7 stock markets, with a diameter of 1.2mm and a grade of H10Mn2.

[0050] (2) One strand of solid-core welding wire is used as the central wire, and the rest of the welding wire is used as the peripheral wire, and the existing stranding machine is used to twist into a multi-strand wire blank.

[0051] (3) The active agent is prepared according to the following mass percentage, 60% SiO 2 , 10%TiO 2 , 10%Cr 2 o 3 , 5% NaF, 6% LiF, 8% potassium fluozirconate, 0.5% sodium stearate, 0.5% yttrium oxide.

[0052] Mix the above components in a conventional powder mixer for 12 minutes according to the formula, grind the mixed powder with a ball mill, and pass through a 460-mesh sieve (with a diameter not exceeding 0.03mm) to obtain the active agent powder.

[0053] (4) Carry out boronization treatment to the multi-strand wire welding wire blank made in step (2) according to the existing process, so that its surface is adhered...

Embodiment 3

[0059] (1) Select 7 strands of welding steel wire with a diameter of 4.0 mm and a brand name of H08A that have been cleaned of oil and rust on the surface.

[0060] (2) One strand of solid-core welding wire is used as the central wire, and the rest of the welding wire is used as the peripheral wire, and the existing stranding machine is used to twist into a multi-strand wire blank.

[0061] (3) The active agent is prepared according to the following mass percentage, 50% SiO 2 , 20%TiO 2 , 15%Cr 2 o 3 , 11% LiF, 2% potassium fluozirconate, 1.0% sodium stearate, 1.0% yttrium oxide.

[0062] Mix the above components in a conventional powder mixer for 12 minutes according to the formula, grind the mixed powder with a mortar until it passes through a 460-mesh sieve (with a diameter not exceeding 0.03mm), and obtain the active agent powder.

[0063] (4) Carry out boronization treatment to the multi-strand wire welding wire blank made in step (2) according to the existing process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com