Preparation method of graphene quantum dots

A graphene quantum dot and graphene technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of cumbersome, widened fluorescence wavelength, low quantum yield, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

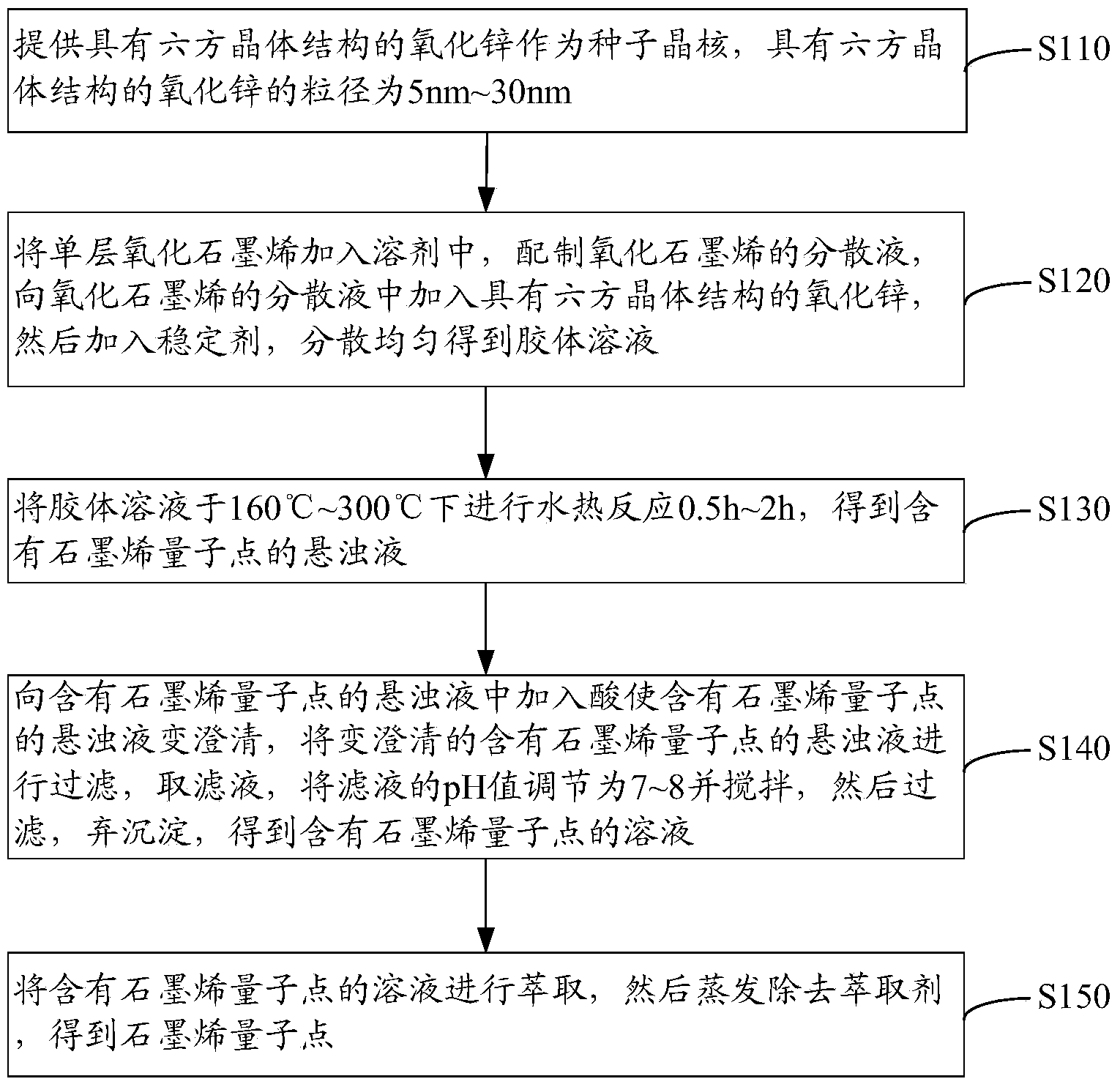

[0028] see figure 1 , a method for preparing graphene quantum dots in one embodiment, including the following steps 110 to 150.

[0029] Step 110: providing zinc oxide with a hexagonal crystal structure as a seed crystal nucleus, and the particle size of the zinc oxide with a hexagonal crystal structure is 5nm-30nm.

[0030] The [1000] and [1111] crystal planes of zinc oxide having a hexagonal crystal structure are the exposed crystal planes. Graphene and graphene oxide are easier to grow on the [1000] and [1111] crystal planes of zinc oxide with a hexagonal crystal structure. Zinc oxide with a hexagonal crystal structure is used as a seed nucleus to induce the growth of graphene quantum dots, and the size of graphene quantum dots can be indirectly controlled by controlling the particle size of zinc oxide with a hexagonal crystal phase structure.

[0031] The particle size of zinc oxide having a hexagonal crystal structure is 5 nm to 30 nm. Zinc oxide with a hexagonal cryst...

Embodiment 1

[0070] 1. Dissolve zinc acetate in ethanol, heat in a water bath at 50°C for 1 hour, then add polymethylpyrrolidone to obtain the first solution. Wherein, the mass percent concentration of zinc acetate is 5%, and the mass percent concentration of polymethylpyrrolidone is 0.2%. Mix ammonia water with a mass percent concentration of 25% and absolute ethanol at a volume ratio of 1:5 to prepare a mixed solution of ammonia water and ethanol, and add sodium hydroxide to obtain a second solution. Wherein, the concentration of sodium hydroxide in the second solution is 0.1mg / L. Mix the first solution and the second solution at a volume ratio of 1:1, stir at a rate of 60rpm for 2h, then centrifuge at a rate of 3000rpm for 5min, take the precipitate, wash the precipitate to obtain zinc oxide with a hexagonal crystal structure, which has a hexagonal crystal structure The zinc oxide is spherical and the particle size is 7.5nm.

[0071] 2. Add single-layer graphene oxide to deionized wat...

Embodiment 2

[0077] 1. Dissolve zinc chloride in isopropanol, heat in a water bath at 60°C for 2 hours, then add hydroxypropyl cellulose to obtain the first solution. Wherein, the mass percentage concentration of zinc chloride is 25%, and the mass percentage concentration of hydroxypropyl cellulose is 1%. Mix ammonia water with a mass percent concentration of 25% and absolute ethanol at a volume ratio of 1:8 to prepare a mixed solution of ammonia water and ethanol, and add potassium hydroxide to obtain a second solution. Wherein, the concentration of potassium hydroxide in the second solution is 0.5mg / L. The first solution and the second solution were mixed at a volume ratio of 2:1, stirred at a rate of 30rpm for 3h, then centrifuged at a rate of 4000rpm for 15min, the precipitate was taken, and the precipitate was washed to obtain zinc oxide with a hexagonal crystal structure, which had a hexagonal crystal structure The zinc oxide is hexagonal and the particle size is 15nm.

[0078] 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com