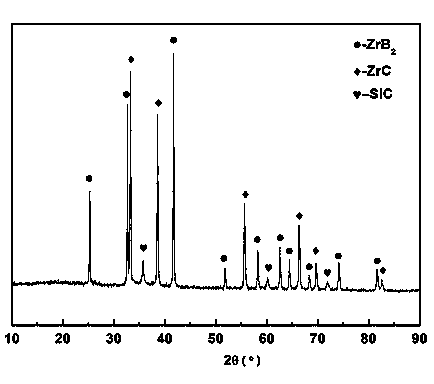

SiC-ZrC-ZrB2 nano complex phase ceramic modified C/C composite material and preparation method thereof

A technology of multiphase ceramics and composite materials, which is applied in the field of C/C composite materials, can solve the problems of difficult uniform distribution of ceramic particles, reduce the high temperature performance of C/C composite materials, etc., achieve good physical and chemical compatibility, improve Mechanical properties, the effect of enhancing self-healing antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation steps of the ZrC precursor are as follows: vacuumize the reactor to 0.06-0.08MPa, feed argon to normal pressure, then add toluene, zirconium salt and absolute ethanol to the reactor in sequence, and stir evenly. Wherein: the molar ratio of zirconium salt: toluene: absolute ethanol is 1: (3~5): (4~10); then feed ammonia gas under the condition of -10~10°C, and the flow rate of feeding ammonia gas is 40~60ml / min, react for 2~6h, and filter to obtain a toluene solution of zirconium alkoxide.

[0042] The reactor is evacuated to 0.06~0.08MPa, argon is introduced to normal pressure, and then the toluene solution of zirconium alkoxide, β-diketone and phenol are sequentially added to the reactor, and stirred evenly, wherein: β-diketone: phenol: The molar ratio of zirconium salt is (1~4):(2~4):1; then the reaction system is heated to 120~300°C at a heating rate of 2~4°C / min, kept for 1~10h, and depressurized Distill and cool to room temperature to obtai...

Embodiment 1

[0044] A SiC-ZrC-ZrB 2 A nanocomposite ceramic modified C / C composite material and a preparation method thereof. The concrete steps of described preparation method are:

[0045] Step 1. Pretreatment of carbon fiber preform

[0046] The carbon fiber preform was washed with acetone for 30-60 minutes, and dried at 70-100°C for 1-2 hours to obtain a pretreated carbon fiber preform.

[0047] Step 2, preparation of borosilicate zirconium doped pitch

[0048] Dissolve the asphalt in toluene first, let it stand at room temperature for 1~2h, separate the solid and liquid, and distill the solution after the solid-liquid separation at 110~150°C to obtain the asphalt toluene soluble component.

[0049] Mix 1-2wt% organic boron, 5-6wt% organic silicon, 10-12wt% ZrC precursor and 80-84wt% asphalt toluene soluble components to obtain the mixture. Add a solvent to the mixture, the mass ratio of the mixture to the solvent is 1:(1~2), stir magnetically for 0.5~1h, and the mixture is obt...

Embodiment 2

[0064] A SiC-ZrC-ZrB 2 A nanocomposite ceramic modified C / C composite material and a preparation method thereof. The concrete steps of described preparation method are:

[0065] Step 1 is the same as Step 1 in Embodiment 1.

[0066] Step 2, preparation of borosilicate zirconium doped pitch

[0067] Dissolve the asphalt in toluene first, let it stand at room temperature for 1~2h, separate the solid and liquid, and distill the solution after the solid-liquid separation at 110~150°C to obtain the asphalt toluene soluble component.

[0068] Mix 2-3wt% organoboron, 6-7wt% organosilicon, 12-14wt% ZrC precursor and 76-80wt% asphalt toluene soluble components to obtain the mixture. Add a solvent to the mixture, the mass ratio of the mixture to the solvent is 1:(1~2), stir magnetically for 0.5~1h, and the mixture is obtained. Then the mixed solution is transferred to the reaction kettle, and an inert gas is introduced, and the reaction kettle is heated to 300~350°C at a heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com