Preparation method for chitin-rich compound fertilizer

A technology of compound fertilizer and chitin, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of limited application and high price, and achieve the effect of enhancing leaf photosynthesis, low cost, and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

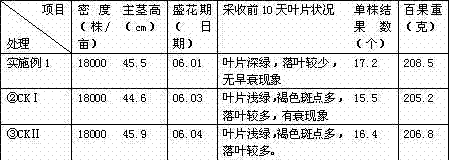

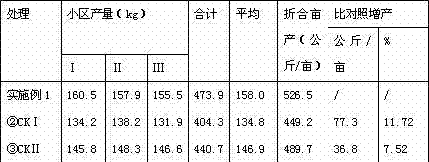

Examples

Embodiment 1

[0024] A preparation method of a compound fertilizer rich in chitin, comprising the steps of:

[0025] Select magnesium oxide, pulverize through a 60-mesh sieve to obtain medium element powder, and set aside; select zinc oxide, ferrous oxide, copper oxide, manganese oxide, boric acid, and pulverize respectively through a 60-mesh sieve, and press zinc oxide 60%, ferrous oxide 10%, 5% copper oxide, 5% manganese oxide, and 20% boric acid are mixed evenly to obtain trace element powder, which is set aside; select cellulase and protease, and mix evenly according to the ratio of cellulase 67% and protease 33%, to obtain a compound Enzyme, spare; preparation of compound enzyme solution: pre-activate the above compound enzyme with the ratio of cellulase: protease = 2:1 with warm water (35-40°C) according to the compound enzyme: warm water mixing ratio of 1:80 , the activation time is 30 minutes, ready to use;

[0026] Chitin preparation: select the mycelium residue of wet basis (wate...

Embodiment 2

[0034] A preparation method of a compound fertilizer rich in chitin, comprising the steps of:

[0035]Select calcium oxide, pulverize through a 60-mesh sieve to obtain medium element powder, and set aside; select zinc oxide, ferrous oxide, copper oxide, manganese oxide, and boric acid, and pulverize them through a 60-mesh sieve respectively, and press zinc oxide 70%, ferrous oxide 5%, copper oxide 5%, manganese oxide 5%, and boric acid 15% were mixed evenly to obtain trace element powder, which was set aside; select cellulase and protease, and mix evenly according to the ratio of 50% cellulase and 50% protease to obtain compound Enzyme, spare; preparation of compound enzyme solution: pre-activate the above compound enzyme with the ratio of cellulase: protease = 2:1 with warm water (35-40°C) according to the compound enzyme: warm water mixing ratio of 1:80 , the activation time is 30 minutes, ready to use;

[0036] Chitin preparation: select the mycelium residue of wet basis (...

Embodiment 3

[0044] A preparation method of a compound fertilizer rich in chitin, comprising the steps of:

[0045] Select magnesium oxide and calcium oxide, pulverize them through a 60-mesh sieve, respectively, to obtain medium element powder, and set aside; select zinc oxide and boric acid, pulverize them through a 60-mesh sieve, and mix them uniformly according to the ratio of 70% zinc oxide and 30% boric acid to obtain trace element powder. Elemental powder, spare; select cellulase, protease, mix evenly according to the ratio of cellulase 67% and protease 33%, obtain compound enzyme, reserve; compound enzyme liquid preparation: mix the above-mentioned cellulase: protease=2:1 ratio A certain amount of compound enzyme is pre-activated with warm water (35-40°C) according to the compound enzyme: warm water mixing ratio of 1:80, and the activation time is 30 minutes. It is prepared and used immediately;

[0046] Chitin preparation: select the mycelium residue of wet basis (water content 60%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com