Complex titanium and calcium sulfonate lubricating grease and preparation method thereof

A compound calcium titanium sulfonate lubricating grease and the technology of compound calcium titanium sulfonate are applied in lubricating compositions, petroleum industry, thickeners, etc., and can solve the problems of high temperature resistance, water spray resistance and high temperature resistance of grease Insufficient resistance to water splashing, blockage of centralized lubrication pipelines, etc., to achieve excellent noise reduction effects, shorten preparation time, and super long lubrication life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

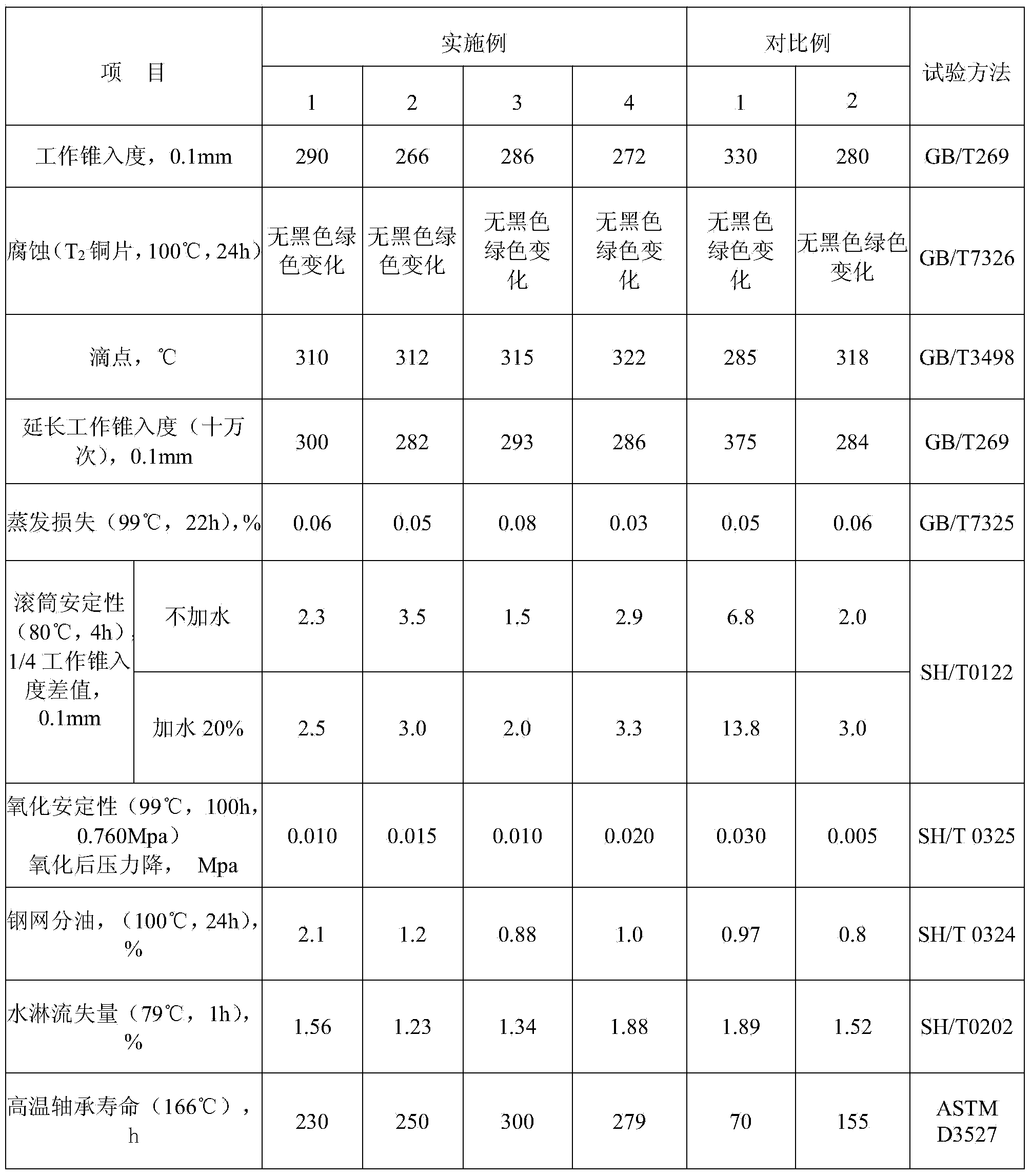

[0033] Add 240g of 150BS oil, 40g of trimethylolpropane, 6g of ethyl acetate, 24g of stearic acid, and 7g of terephthalic acid into the kettle, heat to 65°C, then slowly add 12g of tetraisopropyl titanate, and keep warm for 30min After the heat preservation is over, heat slowly to raise the temperature to 90°C, add 5g of distilled water, heat and stir for 20 minutes, and after the heat preservation is over, add 35g of high-basic calcium sulfonate T106E for grease (Henan Ruifeng Chemical Industry), 1.4g of acetic acid and mix well. Stir and react for 30 minutes, then heat up to 180°C, keep stirring for 30 minutes, then stop heating, add 60g of cold 150BS oil, wait until the temperature drops to 70°C, add 13g of cerium trifluoride and 5g of liquid diphenylamine, and then grind with a three-roll mill Composite calcium titanium sulfonate grease was obtained three times, and its properties are shown in Table 1.

Embodiment 2

[0035] Add 260g of 600SN oil, 20g of pentaerythritol ester, 12g of butyl acetate, 21.6g of stearic acid, 2.4g of dodecyl hydroxystearic acid, and 5.8g of salicylic acid into the kettle, heat to 90°C, and then add 12g of tetraisopropyl titanate Slowly add the ester and keep it warm for 20 minutes. After the heat preservation is over, heat slowly to raise the temperature to 98°C. Add 5g of distilled water, keep it warm and stir for 20 minutes. Mix g heavy alkylbenzene sulfonic acid evenly, stir and react for 30min, then heat to 160°C, keep stirring for 60min, then stop heating, add 60g cold 600SN oil, wait until the temperature drops to 90°C, add 14g zinc dithiomolybdate, 3g of liquid diphenylamine and 3g of diisooctyldiphenylamine were ground three times by a three-roll mill to obtain the complex calcium titanium sulfonate grease, and its properties are shown in Table 1.

Embodiment 3

[0037] Add 220g of 150BS oil, 60g of pentaerythritol ester, 6g of isopropanol, 6g of n-butanol, 24g of stearic acid, and 5.8g of salicylic acid into the kettle, heat to 80°C, then slowly add 21g of tetraisopropyl titanate, and keep warm 30min, after the heat preservation is over, heat slowly to raise the temperature to 100°C, add 6g of distilled water, keep warm and stir for 20min, at this temperature, add 50g of high-basic calcium sulfonate T106E for grease, 5g of heavy alkylbenzene sulfonic acid and mix well , stirred and reacted for 30 minutes, then heated to 160°C, kept stirring for 30 minutes, then stopped heating, added 60g of cold 150BS oil, and when the temperature dropped to 80°C, added 10g of cerium trifluoride, 5g of fluorinated graphite and 8g of liquid diphenylamine, and then Composite calcium titanium sulfonate grease was obtained by grinding three times with a three-roll mill, and its properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com