Method for manufacturing double-sided polarizing plate and double-sided polarizing plate manufactured by same

A polarizing plate, a single technology, applied in the direction of chemical instruments and methods, optics, polarizing elements, etc., can solve the deterioration of optical physical properties and reworkability, the deterioration of adhesive strength and peel strength of non-light-irradiated surfaces, and the adhesive layer To solve problems such as different curing degrees, achieve excellent peel strength and appearance characteristics, excellent reprocessing performance, and improve the effect of curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0133] Preparation Example 1: Preparation of Transparent Base Film

[0134] A kind of resin composition, will wherein with the weight ratio of 100:2.5:5:5 homogeneously mix poly(N-cyclohexylmaleimide-co-methyl methacrylate) resin, styrene-anhydrous to acid copolymer resins and phenoxy-based resins, and to feed An extruder in which the space from the feed hopper to the extruder was replaced with nitrogen, and melted at 250° C. to prepare feed pellets.

[0135] Use PKFE (MW=60000, Mn=16000, Tg=95°C; purchased from ) as a phenoxy-based resin, Dylaeck332 containing 85% by weight of styrene and 15% by weight of anhydrous maleic acid was used as a styrene-maleic anhydride copolymer resin, and poly(N-cyclohexylmaleic acid) was analyzed by NMR. imide-co-methylmethacrylate) resin, analyzed by NMR. As a result, the content of N-cyclohexylmaleimide was 6.5% by weight.

[0136] The resulting feed pellets were dried under vacuum, melted in an extruder at 260 °C, and passed through a ...

preparation Embodiment 2

[0138] Preparation Example 2: Preparation of Adhesive Composition

[0139] (1) Adhesive composition A

[0140] Add 5 parts by weight of cationic initiator CPI100P (available from Sanapro) and 5 parts by weight of vinyltriethylsilane to 100% by weight of the resin composition to prepare adhesive composition A for polarizing plates, Wherein said 100% by weight resin composition is by adding 25% by weight of 3,4-epoxycyclohexylmethyl-3,4'-epoxycyclohexanecarboxylate (Celloxide 2021P purchased from Dicel), 25% by weight % of 1,4-cyclohexanedimethanol diglycidyl ether and 50% by weight of 3-ethyl-3-[(3-ethyloxetan-3-yl)methoxymethyl] Oxetane (Toa Gosei Aaron Oxetane DOX221).

[0141] (2) Adhesive composition B

[0142] 5 parts by weight of cationic initiator CPI100P (purchased from Sanapro) was added to 100% by weight of the resin composition to prepare adhesive composition B for polarizing plates, wherein the 100% by weight of the resin composition was 25% by weight of 1,4-cyc...

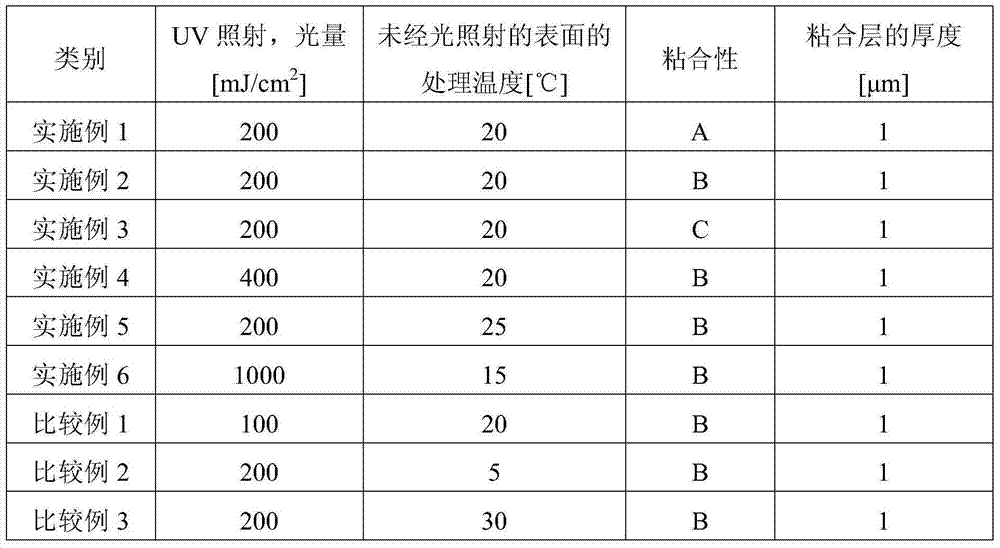

Embodiment 1

[0146] The primer layer of the two-layer acrylic film prepared in Preparation Example 1 was coated with the adhesive composition A using a micro gravure coater so that the final thickness of each adhesive layer was 1 μm. Thereafter, both acrylic films coated with the adhesive composition were laminated to both surfaces of the PVA element. Then, adopt UV irradiation system (fusion lamp, D lamp) to 200mJ / cm 2 Ultraviolet light of a certain amount of light irradiates one surface of the PVA element in one direction, and at the same time closely adheres the surface of the acrylic film opposite to the UV irradiation system to the roller. The temperature of the drum was adjusted to 20° C. to manufacture a polarizing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com