A kind of biological deodorant and preparation method thereof

A biological deodorant and reaction tank technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as affecting the living environment of sewage plants, corroding equipment, and health hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

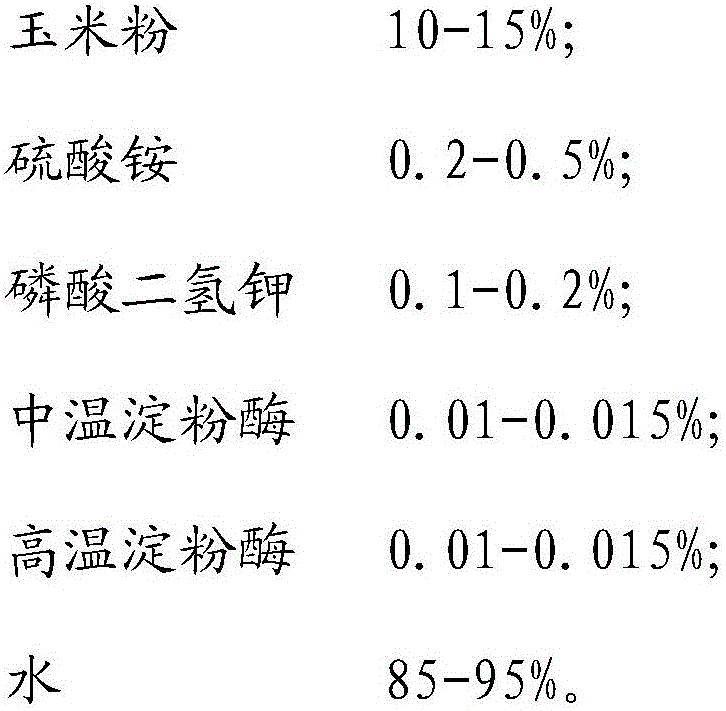

[0016] A biological deodorant of the present invention comprises the following raw materials: corn flour, ammonium sulfate, potassium dihydrogen phosphate, medium-temperature amylase, high-temperature amylase and water, and the mass percentage of each raw material is: the content of corn flour is 10%; The content of ammonium sulfate is 0.2%, the content of potassium dihydrogen phosphate is 0.1%, the content of medium-temperature amylase is 0.01%, the content of high-temperature amylase is 0.01%, and the content of water is 89.68%.

[0017] A preparation method of a biological deodorant, step 1: stirring and mixing step: putting raw materials into a reaction tank and stirring for 60 minutes;

[0018] Step 2: Sterilization and enzymatic hydrolysis: Introduce steam into the reaction tank to slowly raise the temperature in the tank to 70°C, keep the temperature at 70°C for 20 minutes, continue to raise the temperature in the tank to 90°C through steam, and keep warm for 20 Minutes...

Embodiment 2

[0024] A biological deodorant of the present invention comprises the following raw materials: corn flour, ammonium sulfate, potassium dihydrogen phosphate, medium-temperature amylase, high-temperature amylase and water, and the mass percentage of each raw material is: the content of corn flour is 15%; Ammonium sulfate content is 0.5%; potassium dihydrogen phosphate content is 0.2%; medium temperature amylase content is 0.015%; high temperature amylase content is 0.015%; water content is 84.27%.

[0025] A preparation method of a biological deodorant, step 1: stirring and mixing step: putting raw materials into a reaction tank and stirring for 60 minutes;

[0026] Step 2: Sterilization and enzymatic hydrolysis: Introduce steam into the reaction tank to slowly raise the temperature in the tank to 60°C, keep the temperature at 60°C for 10 minutes, continue to raise the temperature in the tank to 80°C through steam, and keep warm 10 minutes, and then continue to heat up the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com