Comprehensive treatment method for wastewater from production of water-soluble fertilizer from poultry manure fermentation liquid

A technology for comprehensive treatment and fermentation liquid, applied in the field of wastewater treatment methods and equipment using microorganisms, can solve the problems of long operation time, secondary environmental pollution, high investment costs, avoid salinity increase, save economic costs, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

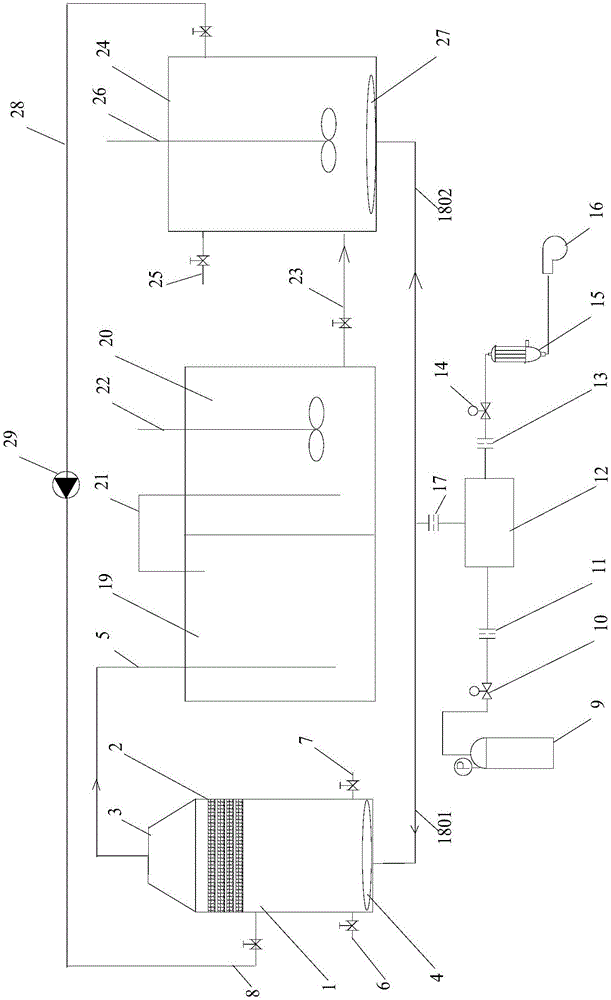

[0048] In the present embodiment, the waste water produced in the process of producing water-soluble fertilizer from the treated chicken manure fermentation liquid has a COD of 80 mg / L, and NH 3 -N concentration is 2012.1mg / L, TP concentration is 3.9mg / L, pH value is 11.3, potassium element concentration is 1428.0mg / L, calcium element concentration is 0.061mg / L, iron element concentration is 0.12mg / L. Such as figure 1 , carrying out the comprehensive treatment of wastewater from the production of water-soluble fertilizer from poultry manure fermentation liquid, using the following equipment: it includes a reactor main body 1, an ammonia-nitrogen gas-liquid absorption unit, a microalgae seed cultivator 24, and an air intake unit;

[0049] The reactor main body 1 is a tank-shaped device, and is provided with a waste water inlet 6 for producing water-soluble fertilizer wastewater from poultry manure fermentation liquid. The bottom of the reactor main body 1 is connected to the ai...

Embodiment 2

[0071] The COD of the chicken manure fermentation liquid water-soluble fertilizer production wastewater that the present embodiment handles is 86mg / L, and NH 3-N concentration is 2100.0mg / L, TP concentration is 4.6mg / L, pH value is 11.5, potassium element concentration is 1320.0mg / L, calcium element concentration is 0.079mg / L, iron element concentration is 0.16mg / L.

[0072] Adopt the equipment identical with embodiment 1, comprehensive processing step:

[0073] 1. Through the water pump, pump the chicken manure fermentation liquid water-soluble fertilizer production wastewater from the waste water inlet 6 into the reactor main body 1 to half the volume of the reactor main body 1;

[0074] 2. Turn on the air compressor 16 and the air heating device 15, the air pressure control valve 14, and adjust the air gas flowmeter 13, so that the air is heated to a temperature of 60°C and enters the reactor through the mixed gas chamber 12 and the gas aeration head 4 The main body 1 is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com