Nanocomposite catalyst and preparation method and application thereof

A technology of nanocomposites and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve low preparation costs, low production costs, and anti-carbon deposition capabilities strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

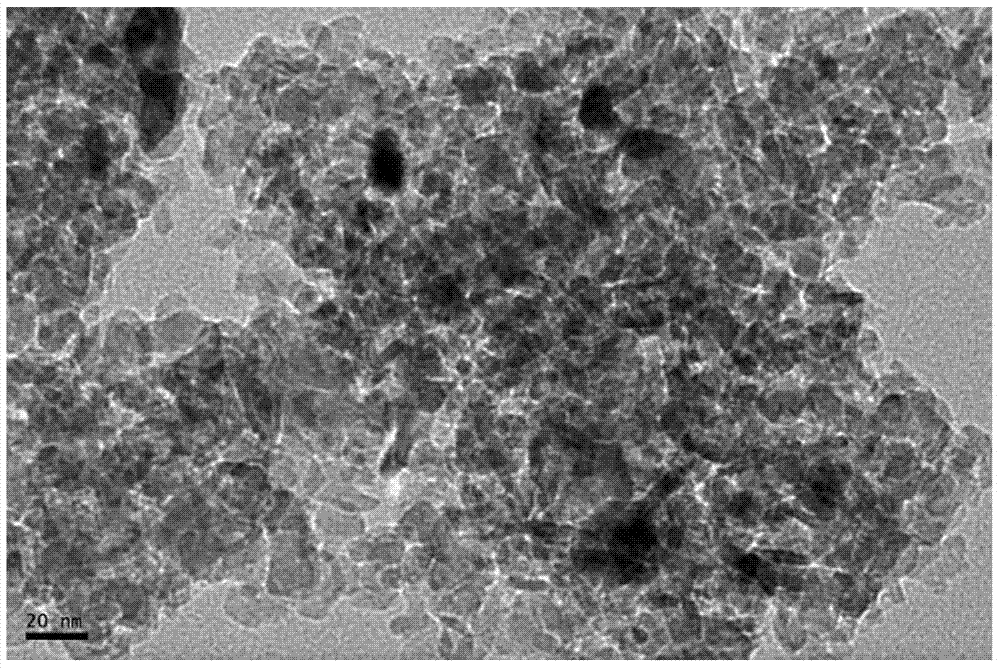

[0047] Example 1 Preparation of high pressure nanocomposite catalyst Ni-Ca-Zr-AlO by co-precipitation method

[0048] The method for preparing high-pressure nanocomposite catalyst Ni-Ca-Zr-AlO by co-precipitation comprises the following steps:

[0049] (1) Preparation of mixed salt solution and alkaline precipitant:

[0050] According to 10g of nanocomposite catalyst, active metal oxide NiO, basic oxide promoter CaO, redox promoter ZrO 2 , carrier Al 2 O 3 The mass ratio of 0.13, 0.06, 0.04, 0.80 to calculate the required mass of nickel nitrate, calcium nitrate, zirconium nitrate and aluminum nitrate, and calculate the required amount of deionized water with the concentration of aluminum nitrate as 0.1mol / L. The required nickel nitrate, calcium nitrate, zirconium nitrate and aluminum nitrate are dissolved in deionized water to prepare a mixed salt solution.

[0051] A NaOH aqueous solution with a concentration of 1 mol / L was prepared as an alkaline precipitant.

[0052] (...

Embodiment 2

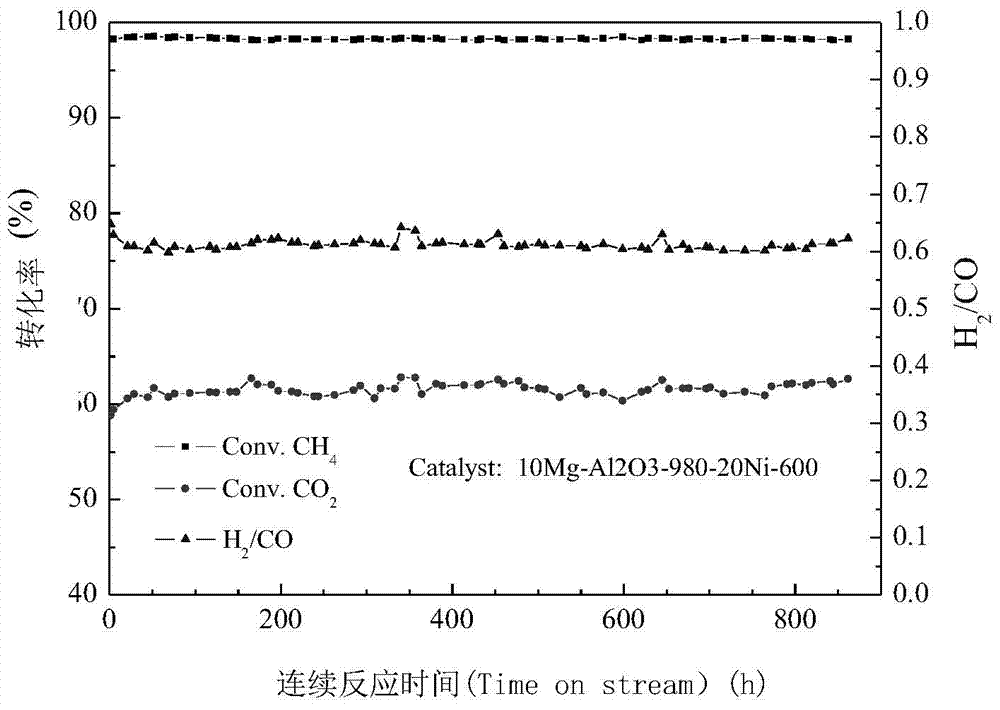

[0062] Example 2 Preparation of high pressure nanocomposite catalyst 20Ni / 10Mg-Al by impregnation method 2 O 3

[0063] Preparation of High Pressure Resistant Nanocomposite Catalyst 20Ni / 10Mg-Al by Impregnation Method 2 O 3 method, including the following steps:

[0064] (1) Modification of carrier γ-alumina

[0065] Weigh a certain amount of γ-alumina and calculate the required Mg(NO) when the MgO loading is 10%. 3 ) 2 ·4H 2 O mass, while calculating the required amount of water according to the measured water absorption of γ-alumina. The resulting mass of Mg(NO) will be calculated 3 ) 2 ·4H 2 O is dissolved in the required water, then added to the γ-alumina, and stirring while adding, try to make the liquid-solid mix as evenly as possible, and let the resulting mixture stand for 2 hours, so that the liquid penetrates completely in the carrier pores (during the period, several times of stirring can be performed) ).

[0066] The impregnated samples were rotary-stea...

Embodiment 3

[0074] Example 3 Preparation of high pressure nanocomposite catalyst 20Ni-2Zr-Al by impregnation method 2 O 3

[0075] Preparation of high-pressure nanocomposite catalyst 20Ni-2Zr-Al by impregnation method 2 O 3 method, including the following steps:

[0076] (1) Modification of carrier γ-alumina

[0077] Weigh a certain amount of 100g γ-alumina, calculate 2g ZrO 2 The mass of zirconium nitrate required for the loading amount, and the amount of water required is calculated according to the measured water absorption of γ-alumina. Dissolve the calculated mass of zirconium nitrate in the required water, then add it to the γ-alumina, stir while adding, try to mix the liquid and solid as evenly as possible, and let the resulting mixture stand for 2 hours to make the liquid penetrate completely in the carrier pores. The impregnated samples were dried in an oven at 50°C for 8 hours, the temperature was increased to 100°C, and the drying was continued overnight. After that, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com