Method for preparing granular random/stereoblock polystyrene

A polystyrene and stereoblock technology, which is applied in the field of granular random/stereoblock polystyrene preparation, can solve problems such as low solubility, and achieve the effects of improving processing performance, preventing adhesion and optimizing processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

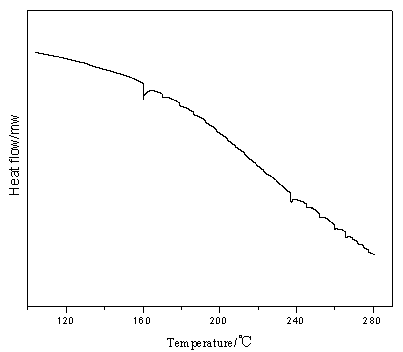

Image

Examples

Embodiment 1

[0031] Under the protection of nitrogen, inject 0.10 mmol of neodymium octanoate, 2.00 mmol of diethylaluminum, 0.13 mmol of dichlorodiethylsilane and 0.1 ml of styrene into the baked ampoule filled with nitrogen, and age it ultrasonically for 45 minutes at 20°C . Inject 11.4 ml of styrene and 10 ml of n-hexane into the polymerization bottle, transfer the aged catalyst to the polymerization bottle, and shake and react at 50°C for 8 hours. Add an acidified ethanol solution containing 5-10% hydrochloric acid to the polymerization bottle to terminate the polymerization reaction, and the reaction product is washed by ethanol precipitation, and vacuum-dried at 40°C to constant weight to obtain granular atactic / stereoblock polyphenylene Ethylene is 6.18 g, the monomer conversion rate is 59.5%, and the weight average molecular weight is 4.61×105.

Embodiment 2

[0033] Under the protection of nitrogen, inject 0.14 mmol of neodymium isooctanoate, 1.40 mmol of triisobutylaluminum, 0.35 mmol of methyldichlorosilane and 0.1 ml of styrene into the baked ampoule filled with nitrogen, and age it ultrasonically at 35°C 60 min. Inject 12.8 ml of styrene and 15 ml of toluene into the polymerization bottle, transfer the aged catalyst to the polymerization bottle, and shake and react at 40°C for 12 h. Add an acidified ethanol solution containing 5-10% hydrochloric acid to the polymerization bottle to terminate the polymerization reaction, and the reaction product is washed by ethanol precipitation, and vacuum-dried at 40°C to constant weight to obtain granular atactic / stereoblock polyphenylene Ethylene is 8.89 g, the monomer conversion rate is 76.2%, and the weight average molecular weight is 8.96×104.

Embodiment 3

[0035] Under the protection of nitrogen, inject 0.16 mmol of neodymium neodecanoate, 4.00 mmol of diisopropylaluminum chloride, 0.05 mmol of propyltrichlorosilane and 0.1 ml of styrene into the ampoule filled with nitrogen after baking, at 50 °C Ultrasonic aging for 90 min. Inject 7.32 ml of styrene into the polymerization bottle, transfer the aged catalyst to the polymerization bottle, and shake and react at 55°C for 18 h. Add an acidified ethanol solution containing 5-10% hydrochloric acid to the polymerization bottle to terminate the polymerization reaction. The reaction product is washed by ethanol precipitation and dried in vacuum at 40 °C to constant weight to obtain 5.73 g of granular polystyrene. The monomer conversion The rate is 85.9%, and the weight average molecular weight is 7.62×104.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com