Chrome-siliconizing infiltrating agent on surface of alloy and preparation method of coating

A chromium-silicon co-infiltration and alloying technology, which is applied in the field of alloy surface coating preparation, can solve the problems of increased brittleness, coating peeling, and affecting performance, etc., and achieves the catalytic effect of anti-carburizing iron-nickel elements, excellent corrosion resistance, The effect of suppressing the catalytic effect of iron and nickel elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

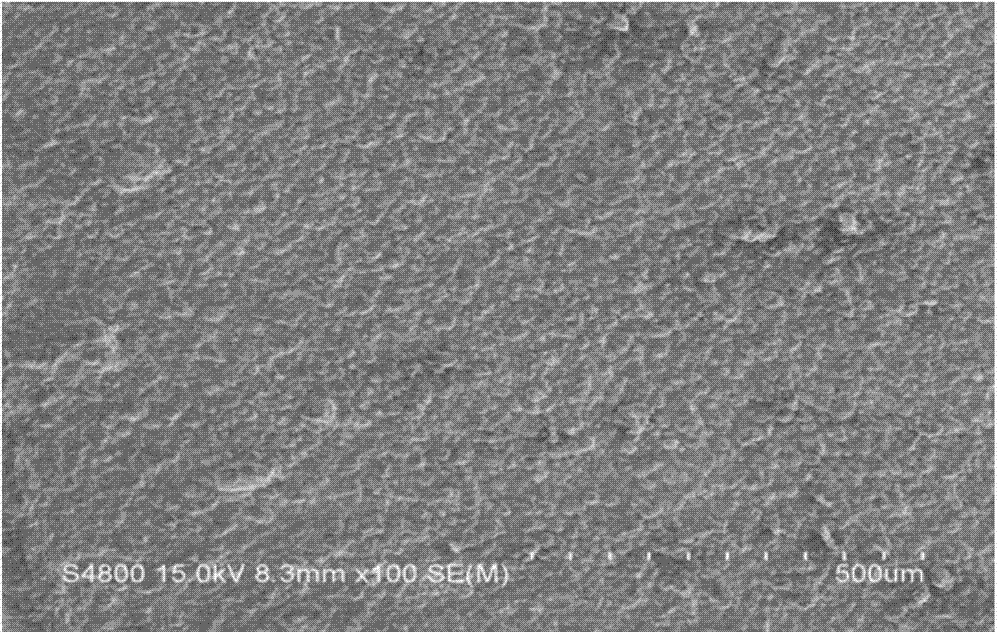

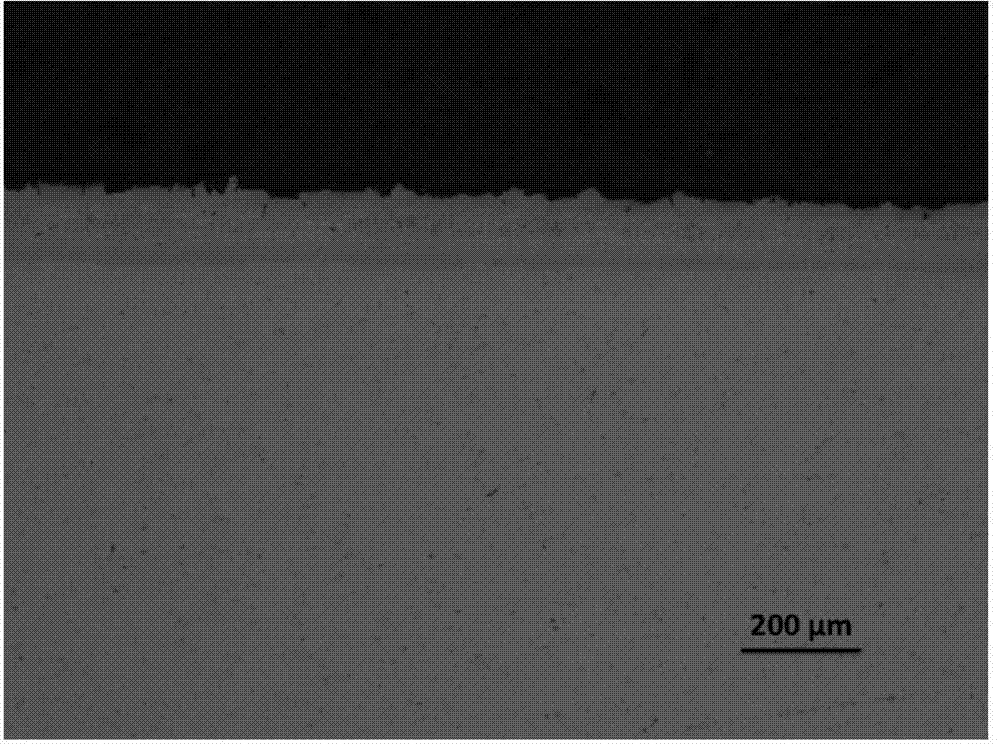

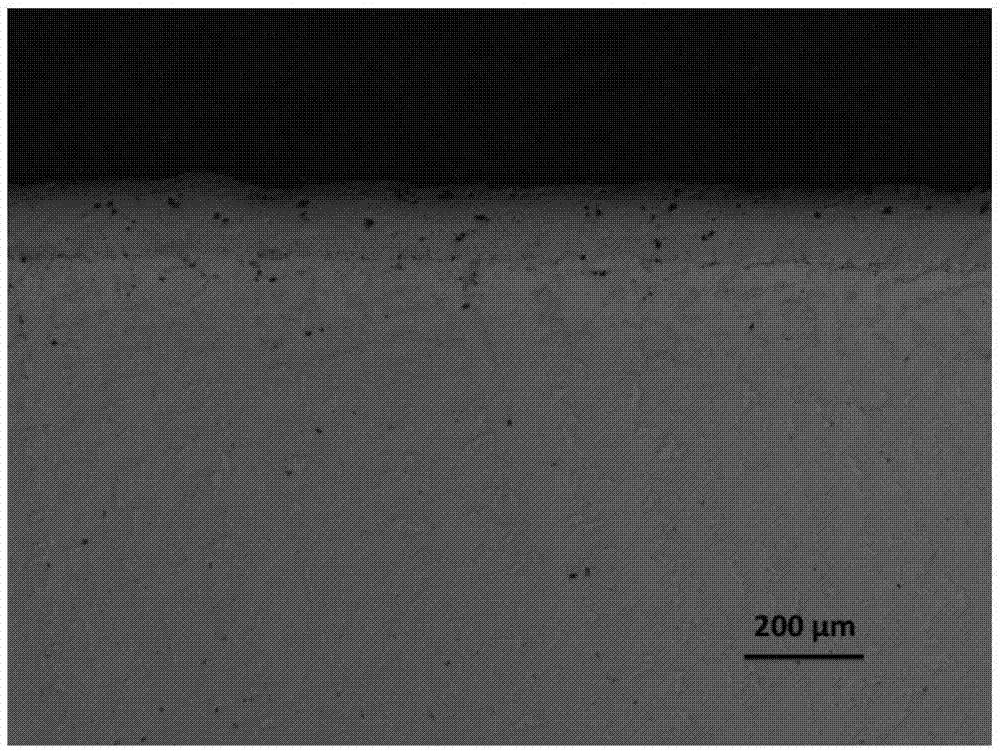

Image

Examples

Embodiment 1

[0034] A kind of alloy surface chromium-silicon infiltrating agent in the present embodiment, comprises the component powder of following percentage by weight: Chromium: 20%, ferrosilicon alloy: 15%; Titanium: 3%; Activator: 2% (ammonium chloride 0.5%, sodium fluoride 1.5%); calcium oxide: 5%; magnesium oxide: 5%; aluminum oxide: the balance. The particle size of the above-mentioned component powders is 150-250 mesh.

[0035] The workpiece material is Cr25Ni35Nb alloy, and the coating preparation process is as follows:

[0036] Step (1): calcining the alumina powder at a temperature of 1100° C. for 2 hours. Weigh each component by weight percentage, stir and mix them evenly, and put them into the infiltration box.

[0037] Step (2): Grind the workpiece with silicon carbide sandpaper to 800#, wash with acetone and blow dry.

[0038] Step (3): Embed the workpiece in the infiltrant and compact it, the distance between the workpiece and the top and bottom is 30mm. Then seal th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com