Plastic protective coating capable of being underwater used and preparation method thereof

A technology for protective coatings and plastics, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of shortening the service life of plastics, not being able to play a protective role, and damaging the health of operators, and achieve a stable protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

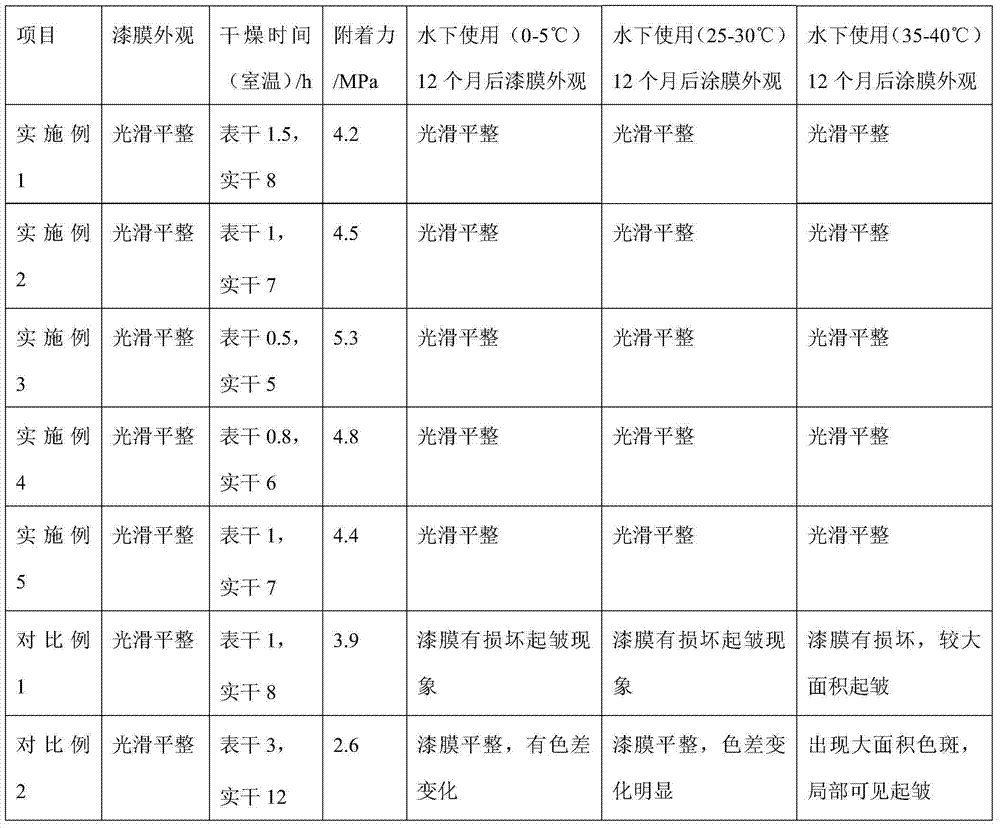

Examples

Embodiment 1

[0021] A plastic protective coating that can be used underwater, comprising: 10 parts of butyl acrylate, 2 parts of stearic acid, 1 part of talcum powder, 0.8 part of antiaging agent D, 0.2 part of silicone defoamer, carbonic acid 2 parts of vinyl ester, 5 parts of ethyl 2-cyanoacrylate, 3 parts of acryloyloxyethyl dimethyl ammonium chloride, 1 part of disodium succinate, 0.8 parts of carboxymethyl cellulose, 8 parts of maleic anhydride, 10 parts of ethyl acetate.

[0022] The preparation method of the above-mentioned underwater plastic protective coating, the steps are as follows:

[0023] Step 1, butyl acrylate, stearic acid, ethylene carbonate, ethyl 2-cyanoacrylate, acryloyloxyethyl dimethyl ammonium chloride, disodium succinate, carboxymethyl cellulose, ethyl acetate Stir and mix with maleic anhydride, and the stirring speed is 200 rpm to obtain material 1;

[0024] Step 2: Add material 1 into the reaction kettle, heat up to 70°C, stir for 50 minutes at a stirring speed...

Embodiment 2

[0027] A plastic protective coating that can be used underwater, comprising by weight components: 16 parts of butyl acrylate, 4 parts of stearic acid, 3 parts of talcum powder, 1 part of antiaging agent D, 0.4 parts of silicone defoamer, carbonic acid 3 parts of vinyl ester, 6 parts of ethyl 2-cyanoacrylate, 4 parts of acryloyloxyethyl dimethyl ammonium chloride, 2 parts of disodium succinate, 1.5 parts of carboxymethyl cellulose, 10 parts of maleic anhydride, 15 parts of ethyl acetate.

[0028] The preparation method of the above-mentioned underwater plastic protective coating, the steps are as follows:

[0029] Step 1, butyl acrylate, stearic acid, ethylene carbonate, ethyl 2-cyanoacrylate, acryloyloxyethyl dimethyl ammonium chloride, disodium succinate, carboxymethyl cellulose, ethyl acetate Stir and mix with maleic anhydride, and the stirring speed is 220 rpm to obtain material 1;

[0030] Step 2: Add material 1 into the reaction kettle, heat up to 75°C, stir for 60 minu...

Embodiment 3

[0033] A plastic protective coating that can be used underwater, comprising by weight components: 17 parts of butyl acrylate, 5 parts of stearic acid, 4 parts of talcum powder, 1.3 parts of antiaging agent D, 0.5 parts of silicone defoamer, carbonic acid 4 parts of vinyl ester, 8 parts of ethyl 2-cyanoacrylate, 6 parts of acryloyloxyethyl dimethyl ammonium chloride, 3 parts of disodium succinate, 1.6 parts of carboxymethyl cellulose, 12 parts of maleic anhydride, 16 parts of ethyl acetate.

[0034] The preparation method of the above-mentioned underwater plastic protective coating, the steps are as follows:

[0035] Step 1, butyl acrylate, stearic acid, ethylene carbonate, ethyl 2-cyanoacrylate, acryloyloxyethyl dimethyl ammonium chloride, disodium succinate, carboxymethyl cellulose, ethyl acetate Stir and mix with maleic anhydride, and the stirring speed is 250 rpm to obtain material 1;

[0036] Step 2: Add material 1 into the reaction kettle, heat up to 76°C, stir for 80 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com