A kind of corrosion-resistant bonding copper wire and preparation method thereof

A copper wire bonding, corrosion-resistant technology, applied in the direction of electrical components, circuits, electrical solid devices, etc., can solve the problems of accelerating copper wires, easy migration of grain boundaries, unsuitable for high density, low radian and multi-layer packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

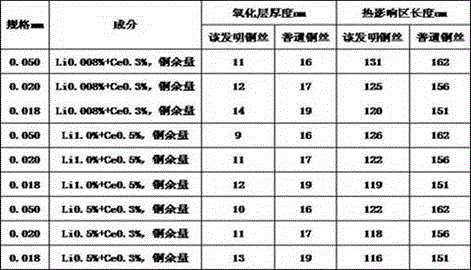

Image

Examples

Embodiment 1

[0013] A specific preparation method of bonding copper wire. Wherein the bonding copper wire raw material is composed of high-purity copper with a purity of not less than 99.9995%, pure Li with a purity of not less than 99.9%, and Ce with a purity of not less than 99.0%. The preparation method is:

[0014] (1) To prepare the bonding copper wire raw material, a vacuum intermediate frequency furnace is used to prepare the bonding copper wire raw material, and the crucible used is zirconia, magnesium oxide or alumina; the preparation process of the bonding copper wire raw material is as follows:

[0015] 1) Weigh 970g of high-purity copper (accounting for 49.4% of the total amount of high-purity copper), and use 10g (accounting for 0.5% of the total amount of high-purity copper) of high-purity copper foil to wrap 20g of pure Li tightly;

[0016] 2) Vacuum the furnace, the vacuum degree is higher than 6×10 -2 Pa, and two high-purity Ar After cleaning, filled with high-purity Ar...

Embodiment 2

[0021] A method for preparing copper bonding wire. Wherein the bonding copper wire raw material is composed of high-purity copper with a purity of not less than 99.9995%, pure Li with a purity of not less than 99.9%, and Ce with a purity of not less than 99.0%. The preparation method is:

[0022] (1) To prepare the bonding copper wire raw material, a vacuum intermediate frequency furnace is used to prepare the bonding copper wire raw material, and the crucible used is zirconia, magnesium oxide or alumina; the preparation process of the bonding copper wire raw material is as follows:

[0023] 1) Weigh 970g of high-purity copper (accounting for 66.2% of the total amount of high-purity copper), and use 10g (accounting for 0.6% of the total amount of high-purity copper) of high-purity copper foil to wrap 20g of pure Li tightly;

[0024] 2) Vacuum the furnace, the vacuum degree is higher than 6×10 -2 Pa, and two high-purity Ar After cleaning, filled with high-purity Ar After r...

Embodiment 3

[0029] A specific preparation method of copper bonding wire.

[0030] Wherein the bonding copper wire raw material is composed of high-purity copper with a purity of not less than 99.9995%, pure Li with a purity of not less than 99.9%, and Ce with a purity of not less than 99.0%. The preparation method is:

[0031] (1) To prepare the bonding copper wire raw material, a vacuum intermediate frequency furnace is used to prepare the bonding copper wire raw material, and the crucible used is zirconia, magnesium oxide or alumina; the preparation process of the bonding copper wire raw material is as follows:

[0032] 1) Weigh 970g of high-purity copper (accounting for 56.5% of the total amount of high-purity copper), and use 10g (accounting for 0.58% of the total amount of high-purity copper) of high-purity copper foil to wrap 20g of pure Li tightly;

[0033] 2) Vacuum the furnace, the vacuum degree is higher than 6×10 -2 Pa, and two high-purity Ar After cleaning, filled with high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com