Preparation method for ABC dry powder extinguishing agent

A technology of dry powder fire extinguishing agent and coupling agent, which is applied in fire prevention equipment, etc., can solve the problems of low fire extinguishing efficiency, large smoke release, and low efficiency, and achieve high moisture-proof and anti-caking performance, low smoke release, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

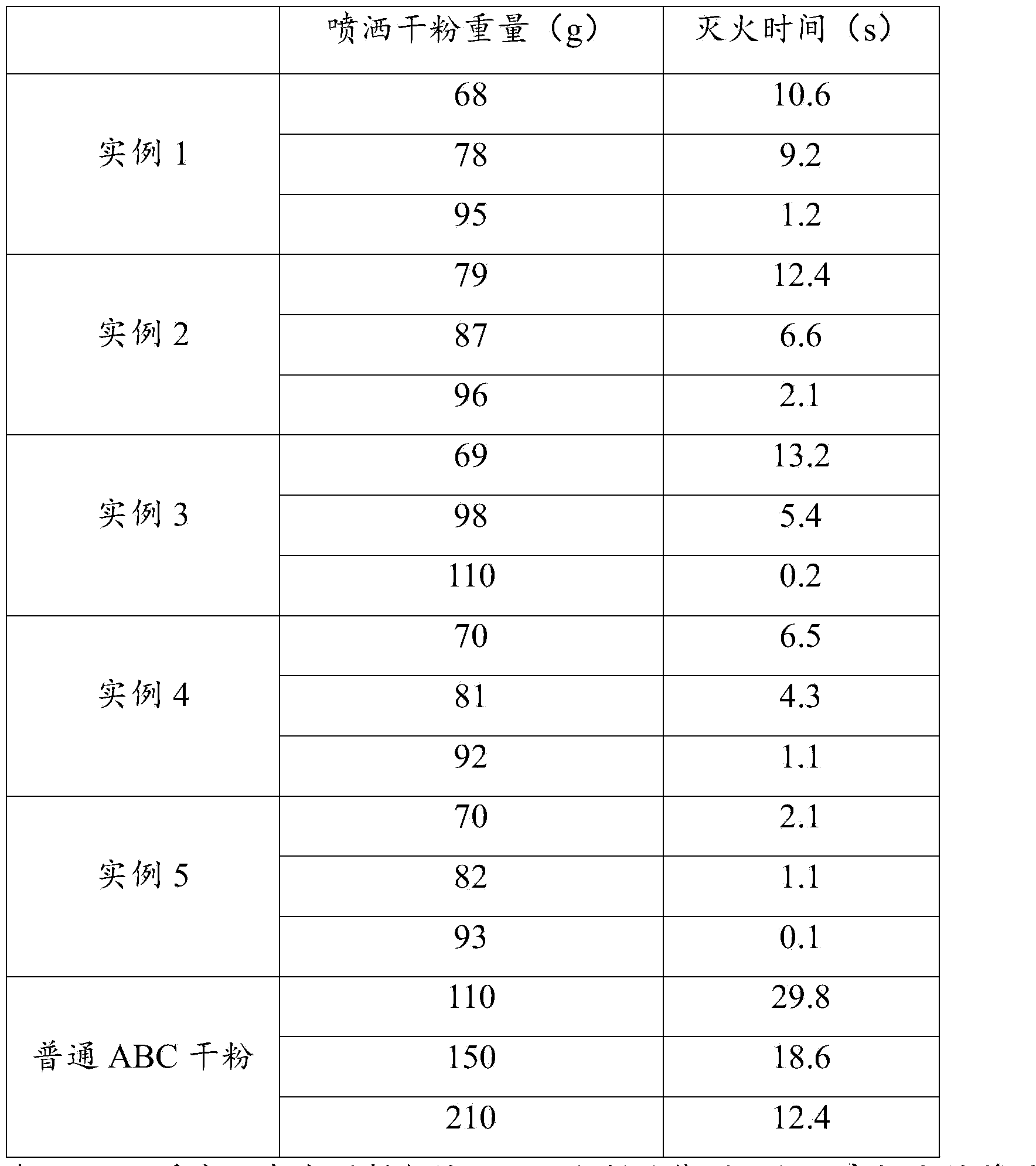

Examples

example 1

[0026] (1) Mix monoammonium phosphate 60g, ammonium sulfate 10g, nano silicon dioxide 5g, muscovite 1g, melamine 1g, pentaerythritol 2g, manganese chloride 0.5g, borax 0.2g, copper acetate 0.1g and vinyltriethoxy Mix 0.2g of silane in a 500ml flask, raise the temperature to 50°C, spray methylphenyl silicone oil into the above mixture with a silicone oil pump, and stir for 30min to obtain product D;

[0027] (2) Use a continuous modified coating machine to crush the product D until more than 50% of the particle size is less than 40 microns, stir at 400 rpm at 70°C for 30 minutes, dry the product at 90°C for 2 hours, cool down to 60°C, and cool After 10 minutes, the ABC dry powder fire extinguishing agent is obtained.

example 2

[0029] (1) Mix 85g of monoammonium phosphate, 27g of ammonium sulfate, 15g of nano-silica, 3g of phlogopite, 2g of melamine, 3g of pentaerythritol, 0.6g of manganese carbonate, 0.2g of borax, 0.4g of copper acetate and vinyltriethoxysilane Mix 0.25g in a 500ml flask, raise the temperature to 60°C, spray simethicone into the above mixture with a silicone oil pump, and stir for 60min to obtain product D;

[0030] (2) Use a continuous modification coating machine to crush the product D until more than 50% of the particle size is less than 40 microns, stir at 1000 rpm at 70°C for 40min, dry the product at 100°C for 3h, cool down to 60°C, and cool After 10 minutes, the ABC dry powder fire extinguishing agent is obtained.

example 3

[0032] (1) 72g of monoammonium phosphate, 18g of ammonium sulfate, 10g of nano-silica, 2g of muscovite, 1.5g of melamine, 2.5g of pentaerythritol, 0.6g of manganese chloride, 0.4g of borax, 0.25g of copper acetate and vinyl triethyl Mix 0.25g of oxysilane in a 500ml flask, raise the temperature to 55°C, spray methylphenyl silicone oil into the above mixture with a silicone oil pump, and stir for 30min to obtain product D;

[0033] (2) Use a continuous modified coating machine to crush the product D until more than 50% of the particle size is less than 40 microns, stir at 70°C for 35min at 700rpm, dry the product at 95°C for 2h, cool down to 60°C, and cool After 15 minutes, ABC dry powder fire extinguishing agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com