Method for preparing high thermoelectrical antimony telluride micro-nano crystal and block material thereof

A technology of antimony telluride micro-nano, thermoelectric properties, applied in the direction of nanotechnology, nanotechnology, binary selenium/tellurium compounds, etc., can solve the problem of large-scale production of antimony telluride micro-nano crystals, low conversion efficiency, equipment Complicated problems, low cost, good thermoelectric performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

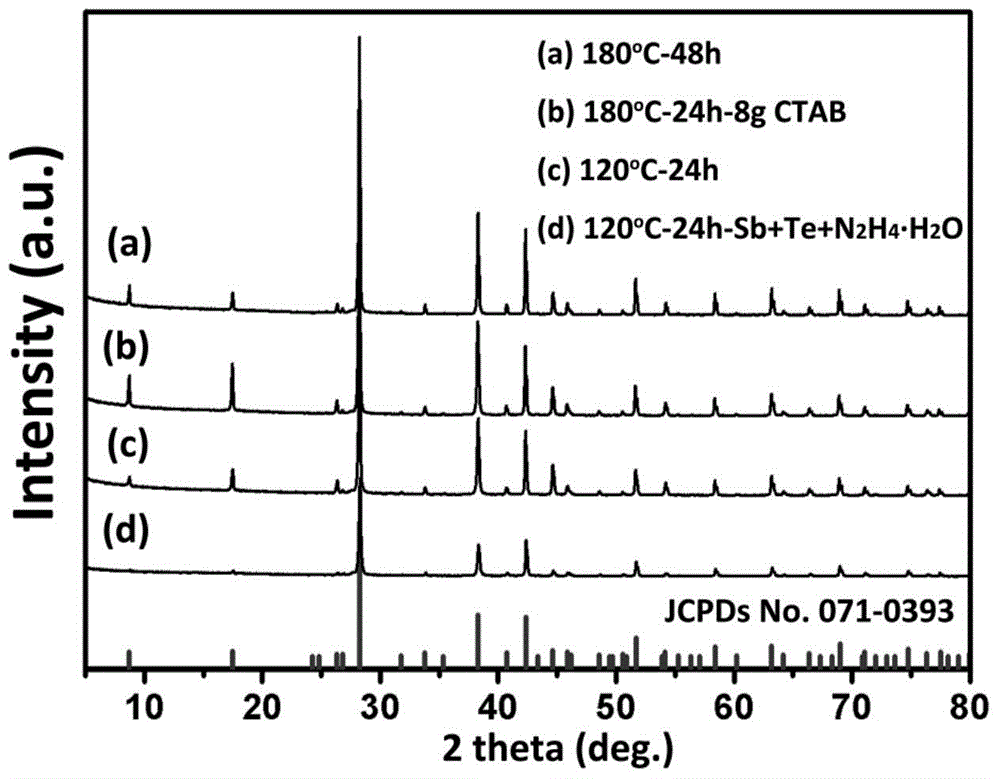

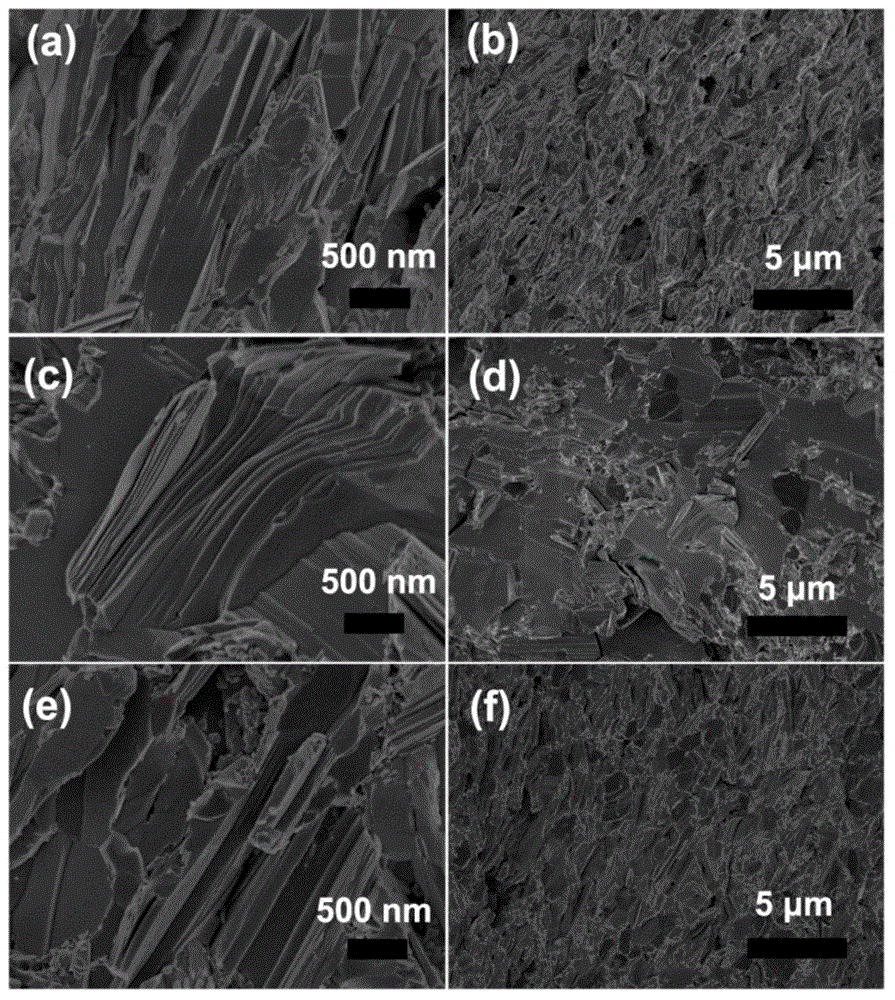

[0045] Weigh 1.3950g antimony trichloride (M(SbCl 3 ) / M(TeO 2 )=0.679, molar ratio) in 50ml of ethylene glycol heated to 50 ~ 100 ℃, stirring completely dissolved and then transferred to a flask containing 1.4364g of tellurium dioxide (0.009mol) and supplemented with ethylene glycol up to 150ml, then It is placed on a heating mantle, heated to 140-180°C, and stirred for 20-40 minutes to obtain a clear and transparent solution. After cooling to 100-120°C, add 4ml of hydrazine hydrate (M(N 2 h 4 ·H 2 O) / M(TeO 2 )=8.962, molar ratio), heated to reflux at 180°C for 48h to obtain a gray precipitate. The obtained product was washed with absolute ethanol and dried in a vacuum environment at 80°C for 8 hours to obtain pure and well-crystallized antimony telluride micro-nanocrystals, whose XRD characterization is shown in figure 1 (a). The antimony telluride micro-nano crystals were cold-pressed into sheet-like blocks under a pressure of 500 MPa, and placed in a tube furnace unde...

Embodiment 2

[0047] Referring to Example 1, the difference is that after adding hydrazine hydrate, the mixture was heated to reflux at 120° C. for 24 hours to obtain a gray precipitate. The obtained product was washed with absolute ethanol and dried in a vacuum environment at 80°C for 8 hours to obtain pure and well-crystallized antimony telluride micro-nanocrystals, whose XRD characterization is shown in figure 1 (c). The antimony telluride micro-nano crystals were cold-pressed into sheet-like blocks under a pressure of 500 MPa, and placed in a tube furnace under 92% Ar + 8% H 2 Annealing at 300°C for 24h under a mixed atmosphere of a protective gas was set at 0.15 L / min, and the annealing heating rate was 5°C / min.

Embodiment 3

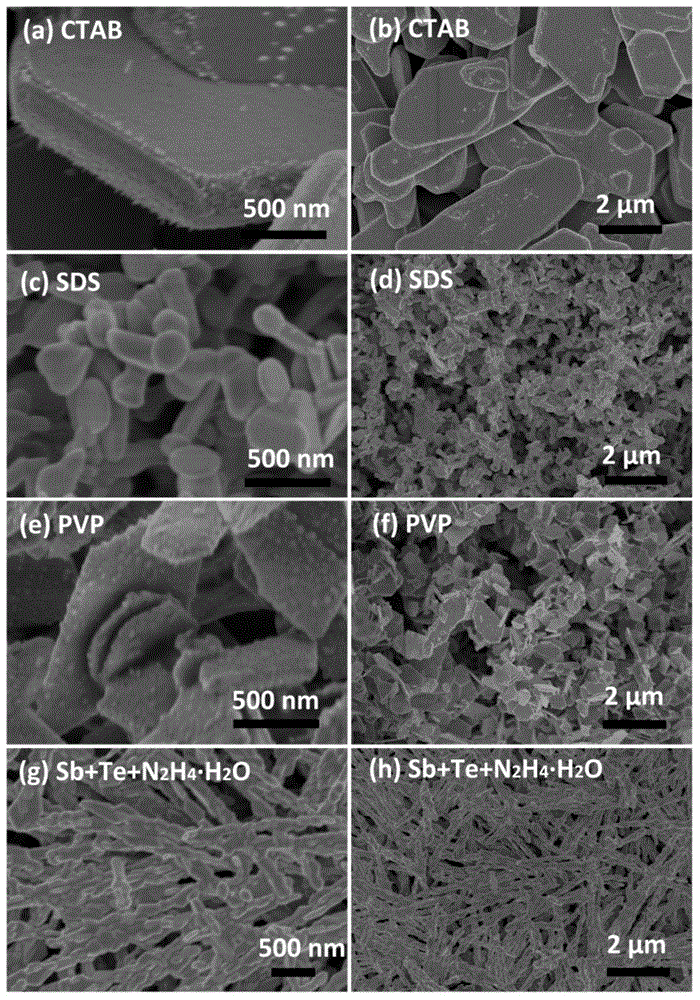

[0049] Weigh 1.3950g antimony trichloride (M(SbCl 3 ) / M(TeO 2 )=0.679, molar ratio) in 50ml of ethylene glycol was heated to 50 ~ 100 ℃, stirring completely dissolved and then transferred to a solution containing 1.4364g tellurium dioxide and 4.0g CTAB (M(CTAB) / M(TeO 2 ) = 1.220, molar ratio) and supplemented with ethylene glycol up to 150ml, then placed it on a heating mantle, heated to 140-180°C, stirred for 20-40min to obtain a clear and transparent solution, and cooled to 100-120 After adding 4ml hydrazine hydrate (M(N 2 h 4 ·H 2 O) / M(TeO 2 )=8.962, molar ratio), heated to reflux at 180°C for 24h to obtain a gray precipitate. The obtained product was washed with absolute ethanol and dried in a vacuum environment at 80°C for 8 hours to obtain pure antimony telluride micro-nanocrystals with good crystallinity. For the SEM characterization, see figure 2 (a).

[0050] The antimony telluride micro-nano crystals were cold-pressed into sheet-like blocks under a pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com