Method for preparing nutritional fertilizer for apples

A nutrient fertilizer and apple technology, which is applied in the direction of fertilization device, fertilizer mixture, phosphate, etc., can solve the problems of non-compliance with apples, pollute the environment, and low absorption rate, and achieve significant environmental protection value, significant economic value, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing apple nutrient fertilizer, comprising the following steps:

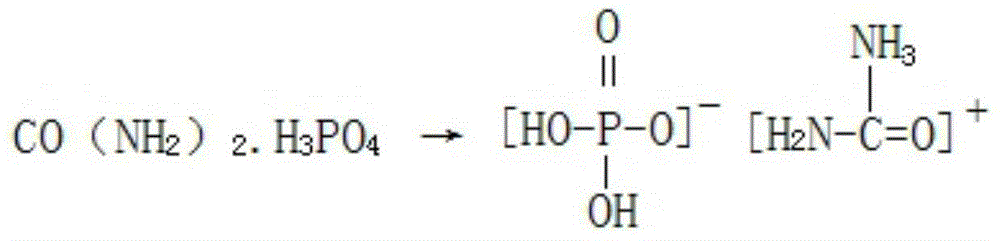

[0040] (1) Preparation of intermediate: first add phosphoric acid to the synthesis tank, and raise the temperature of phosphoric acid to 100°C, then add carbonamide to the synthesis tank to make it react with phosphoric acid, after 200 minutes of reaction, cool down the temperature crystallize after reaching 20°C, and then centrifuge to obtain the intermediate, the molar ratio of phosphoric acid to carbonamide is 1.2:1;

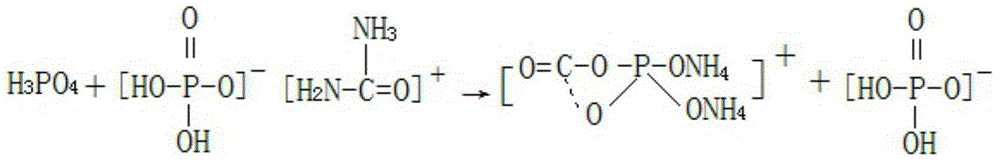

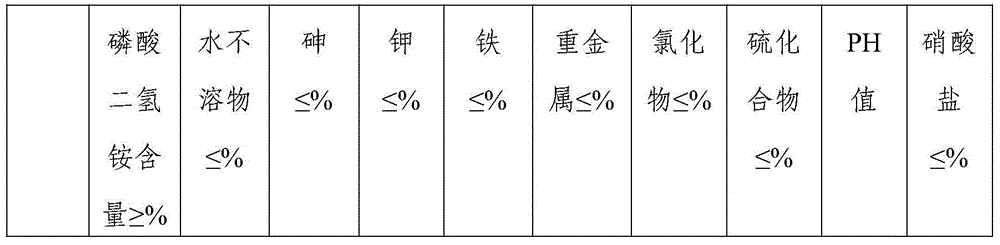

[0041] (2) Preparation of ammonium dihydrogen phosphate: the intermediate obtained in step (1) is sent into the synthesis tank, and ammonia is added in the synthesis tank, the mol ratio of ammonia to the intermediate is 4:1, and the control reaction time is 40min , the reaction temperature is 25°C, the stirring speed is 200r / min to promote the reaction, and the pH value is adjusted to 8. After the reaction is completed, the obtained slurry is added to the cooling crysta...

Embodiment 2

[0046] A method for preparing apple nutrient fertilizer, comprising the following steps:

[0047] (1) Preparation of intermediate: first add phosphoric acid to the synthesis tank, and raise the temperature of phosphoric acid to 130°C, then add carbonamide to the synthesis tank to make it react with phosphoric acid, after 160 minutes of reaction, cool down the temperature crystallize after reaching 40°C, and then centrifuge to obtain the intermediate, the molar ratio of phosphoric acid to carbonamide is 1.4:1;

[0048] (2) Preparation of ammonium dihydrogen phosphate: the intermediate obtained in step (1) is sent into the synthesis tank, and ammonia is added in the synthesis tank, the mol ratio of ammonia to the intermediate is 6:1, and the control reaction time is 60min , stirring at a stirring speed of 200r / min to promote the reaction, the reaction temperature is 15°C, and the pH value is adjusted to 9. After the reaction is completed, the obtained slurry is added to the cool...

Embodiment 3

[0053] (1) Preparation of intermediates: first add phosphoric acid to the synthesis tank, and raise the temperature of phosphoric acid to 120°C, then add carbonamide to the synthesis tank to make it react with phosphoric acid, after 180 minutes of reaction, cool down the temperature crystallize after reaching 30°C, and then centrifuge to obtain the intermediate, the molar ratio of phosphoric acid to carbonamide is 1.3:1;

[0054] (2) Preparation of ammonium dihydrogen phosphate: the intermediate obtained in step (1) is sent into the synthesis tank, and ammonia is added in the synthesis tank, the mol ratio of ammonia to the intermediate is 5:1, and the control reaction time is 50min , the reaction temperature is 20°C, and the pH value is adjusted to 8.5, and the stirring speed is 200r / min to promote the reaction. When the mass ratio of nitrogen and phosphorus pentoxide in the filtrate was 13:6.5, the crystallization was stopped and filtered, and the obtained filter cake was dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com