Functional admixture for improving durability of concrete and cement products and preparation method of functional admixture

A cement product and durability technology, applied in the field of preparation of functional admixtures, can solve the problems of increased fluctuations in the antifreeze performance of concrete and cement products, difficult control of diameter, and impact on the service life of concrete and cement products, etc., to achieve Improve the degree of compactness and volume stability, improve durability, and prevent volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

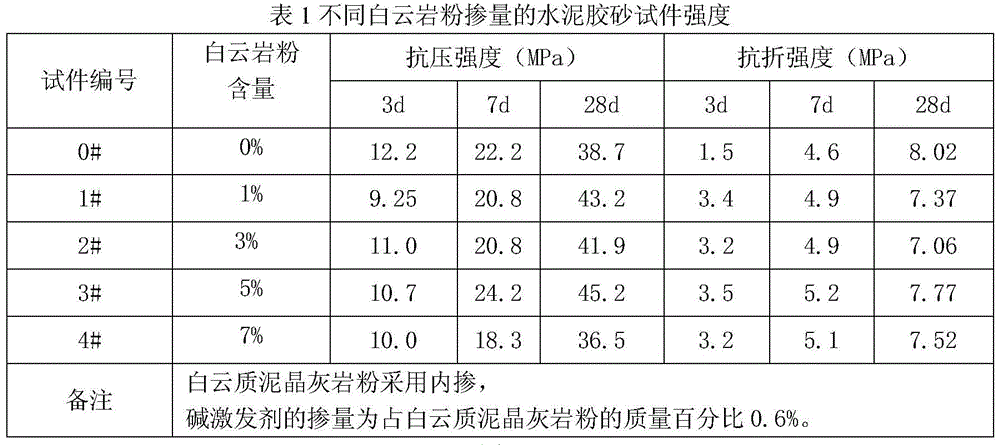

[0044] The preparation method of the functional admixture to improve the durability of concrete and cement products includes the following steps:

[0045] a. Grind the volume expansion carbonate rock with alkali aggregate reaction into cement fineness;

[0046] b. According to 97.0%-99.8% of carbonate rock powder and 0.2%-3.0% of activator, after mixing uniformly, it is made into a functional admixture of high durability concrete or cement products;

[0047] c. Durable functional admixture is added 2%-22% according to the mass of general Portland cement to prepare high-durability concrete or cement products.

[0048] The durable functional admixture is compounded with fly ash and slag powder to prepare the durable functional composite admixture. The mass percentage of the durable functional composite admixture:

[0049] Durable functional admixture 10%-40%

[0050] Fly ash, slag powder 60%-90%

[0051] Mix uniformly to make a functional composite admixture that improves the durability of ...

Embodiment 1

[0052] Example 1 Waterproof and anti-crack plastering mortar

[0053] Waterproof and anti-crack plastering mortar: The waterproof and anti-cracking plastering mortar is composed of PC 32.5 cement: medium sand=1:3, mixed with a durable functional admixture (dolomitic micrite limestone powder 99.7% and 0.3% sodium sulfate). Specifically: cement 370kg, medium sand 1350kg, durability function admixture 37kg and appropriate amount of water.

[0054] A pool with a capacity of about 0.75 cubic meters of water was built with red bricks. After 20 days of plastering with waterproof and crack-resistant plastering mortar, no cracks were seen in the waterproof and crack-resistant plastering mortar, and no leakage occurred when the water was filled for a long time.

Embodiment 2

[0055] Example 2 Waterproof and anti-crack plastering mortar

[0056] The waterproof and anti-cracking plaster mortar is composed of PC 32.5 cement: medium sand = 1:3, mixed with a durable functional admixture (Dolomite powder 99.8% and 0.2% sodium sulfate) that accounts for 10% of the weight of the cement, specifically: Cement is 370kg, medium sand is 1350kg, durable functional admixture is 37kg and appropriate amount of water.

[0057] On the red brick wall with clear water, use waterproof and anti-cracking plastering mortar to plaster three squares of 1 square meter. Seven days later, no cracks were found on the plastered surface of the mortar. Also on the red brick clean water wall, ordinary plastering mortar without durability function admixture is composed of PC 32.5 cement: medium sand=1:3, specifically: cement 370kg, medium sand 1350kg and appropriate amount of water. Use the contrast plastering mortar to plaster three pieces of 1 square meter in size. After 7 days, you ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com