Preparation method of heat-conducting and wave-absorbing composite aerogel and heat-conducting and wave-absorbing composite aerogel

A composite aerogel and composite gel technology, applied in the field of thermally conductive wave absorbing materials, can solve the problems of poor mechanical properties, large shrinkage, poor wave absorbing properties, etc. Insulation performance, the effect of improving absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

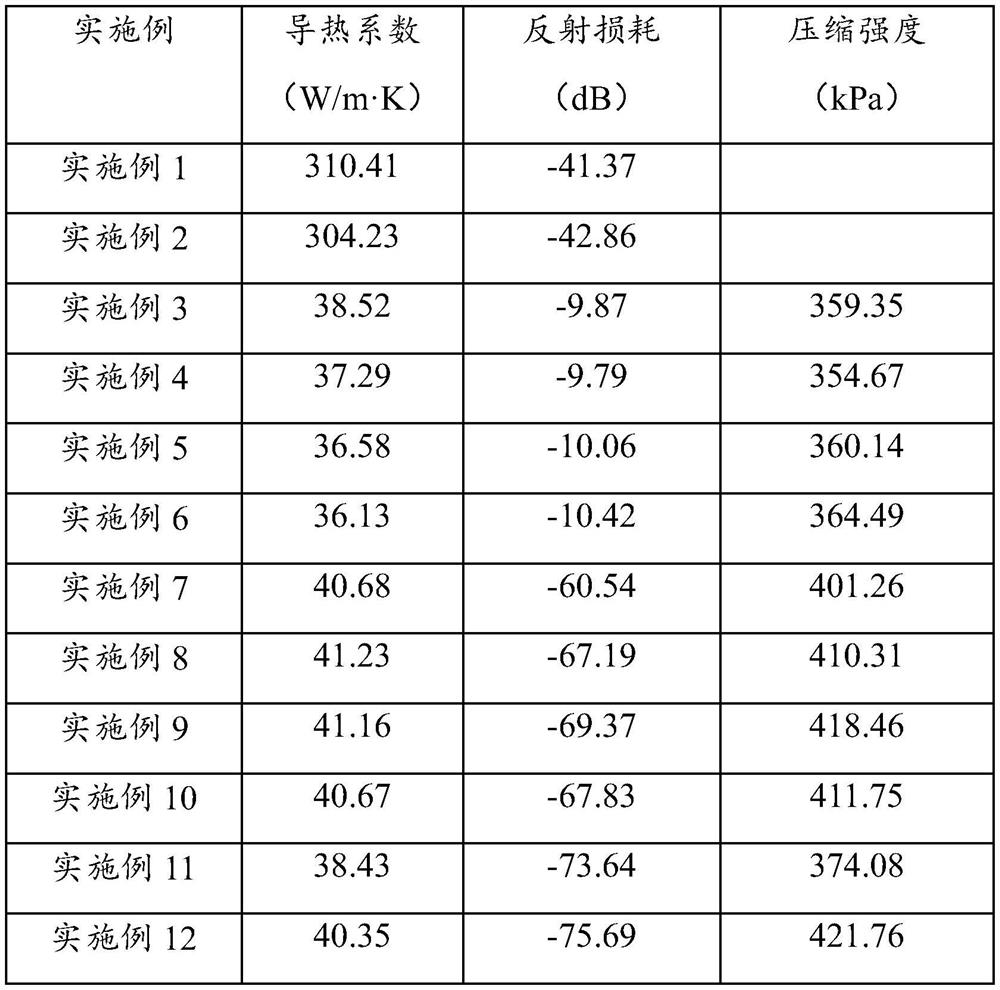

Examples

Embodiment 1

[0031] Porous Magnetic Fe 3 O 4 @SiO 2 Preparation of @MWCNTs ternary nanocomposites:

[0032] (1) 1 g of MWCNTs was added to a mixed solution of 20 mL of deionized water and 80 mL of ethanol, followed by ultrasonic stirring for 30 min to obtain a suspension. 10 mL of ammonia water was added dropwise to the above suspension, and the stirring reaction was continued for 20 min. Then, 2.083 g of ethyl orthosilicate was slowly added dropwise and stirred for mixing, and the stirring reaction was continued for 12 h under water bath conditions. Then, the obtained powder was centrifuged, washed, and dried to obtain tubular SiO with a core-shell structure 2 @MWCNTs nanocomposites. The prepared SiO 2 The @MWCNTs nanocomposite was put into a muffle furnace for high temperature heat treatment, first heated to 400 °C for 3 h, then heated to 650 °C for 3 h, the heating rate was 3 ~ 5 °C / min, and then rapidly cooled to room temperature to obtain a surface rich in Defective core-shell s...

Embodiment 2

[0035] Porous Magnetic Fe 3 O 4 @SiO 2 Preparation of @MWCNTs ternary nanocomposites:

[0036] (1) 1 g of MWCNTs was added to a mixed solution of 20 mL of deionized water and 80 mL of ethanol, followed by ultrasonic stirring for 30 min to obtain a suspension. 10 mL of ammonia water was added dropwise to the above suspension, and the stirring reaction was continued for 20 min. Then, 2.083 g of ethyl orthosilicate was slowly added dropwise and stirred for mixing, and the stirring reaction was continued for 12 h under water bath conditions. Then, the obtained powder was centrifuged, washed, and dried to obtain tubular SiO with a core-shell structure 2 @MWCNTs nanocomposites. The prepared SiO 2 The @MWCNTs nanocomposite was put into a muffle furnace for high temperature heat treatment, first heated to 400 °C for 3 h, then heated to 650 °C for 3 h, the heating rate was 3 ~ 5 °C / min, and then rapidly cooled to room temperature to obtain a surface rich in Oxygen-deficient core-...

Embodiment 3

[0039] Preparation of SA-PA Aerogel:

[0040] 1 g of phytic acid PA (50 wt %) solution was added to 150 mL of deionized water, followed by ultrasonic stirring for 30 min to obtain a uniform suspension. Add 5g of sodium alginate SA to the above suspension, stir vigorously for 1h until the powder is completely dissolved to obtain a uniform SA-PA sol solution, then add 0.2g of gluconolactone to the above sol solution, stir vigorously for 30min to disperse uniform to obtain a precursor composite gel solution. The precursor composite gel solution was poured into a mold, frozen in two-way liquid nitrogen at -30 °C, and dried in a freeze-drying oven for 3 days to obtain SA-PA aerogels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com