Preparation method of powdery red wine

A powdered red wine, powdered technology, applied in the field of powdered red wine, can solve the problems of limited embedding capacity, single cavity size, and restrictions, and achieve the effect of preventing cardiovascular diseases, simple preparation process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

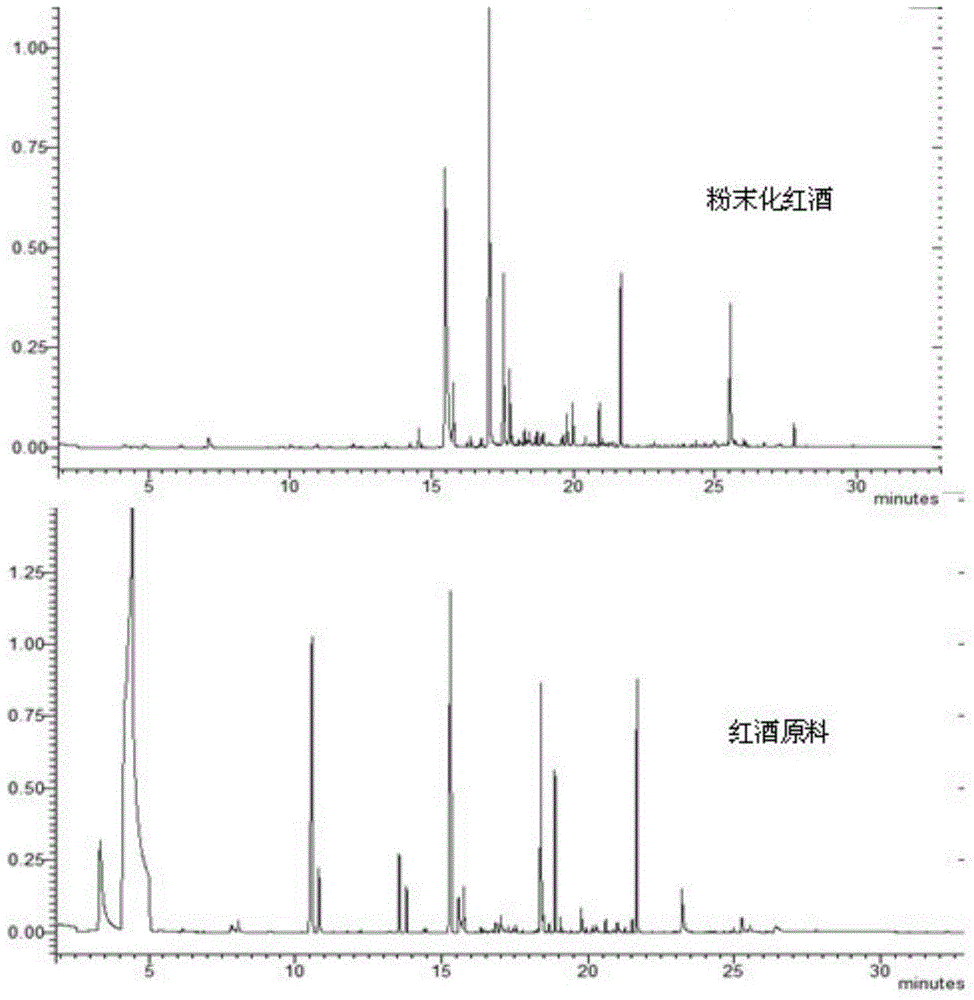

[0027] (1) Preparation of red wine-composite cyclodextrin compound: with commercially available red wine as raw material and commercially available compound cyclodextrin K50 as auxiliary material, 100g of compound cyclodextrin was added to 1L of red wine, sealed with plastic wrap, Stirring at 45°C for 6 hours at a stirring speed of 100 rpm to prepare a red wine-complex cyclodextrin complex;

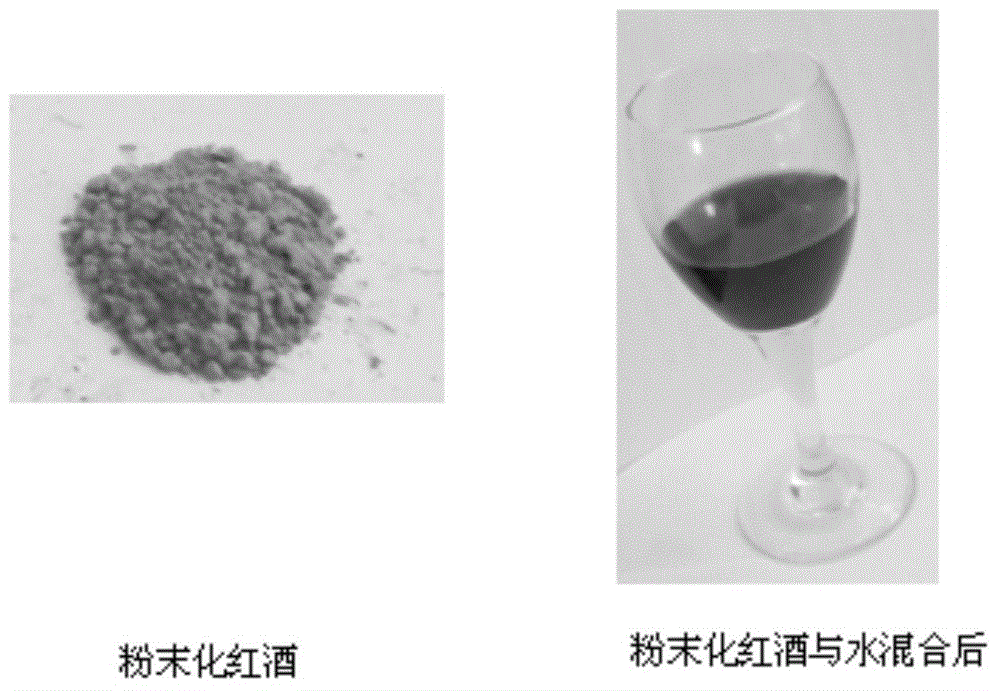

[0028] (2) Red wine powdering: the red wine-cyclodextrin compound prepared in step (1) is spray-dried to obtain powdered red wine (water content 2%); the spray-drying conditions are feed temperature 50°C, homogeneous Pressure 50MPa, air inlet temperature 180°C, air outlet temperature 80°C, spray pressure 100kPa;

[0029] The powdered red wine prepared through the above steps is dissolved in water, wherein the mass ratio of the powdered red wine to water is 1:10 to obtain liquid red wine.

Embodiment 2

[0031] (1) Preparation of red wine-complex cyclodextrin compound: with commercially available white wine as raw material and commercially available compound cyclodextrin K50 as auxiliary material, 150g of compound cyclodextrin was added to 1L of white wine, sealed with plastic wrap, Stir at 52°C for 4 hours at a stirring speed of 150 rpm to prepare a red wine-complex cyclodextrin complex;

[0032] (2) Red wine powdering: the red wine-cyclodextrin compound prepared in step (1) is spray-dried to obtain powdered red wine (water content 5%); the spray-drying conditions are feed temperature 60°C, homogeneous Pressure 30MPa, inlet air temperature 140°C, outlet air temperature 70°C, spray pressure 180kPa;

[0033] The powdered red wine prepared through the above steps is dissolved in water, wherein the mass ratio of the powdered red wine to water is 1:15 to obtain liquid red wine.

Embodiment 3

[0035] (1) Preparation of red wine-complex cyclodextrin compound: with commercially available pink wine as raw material and commercially available compound cyclodextrin K50 as auxiliary material, 125g of compound cyclodextrin was added to 1L of pink wine, sealed with plastic wrap, Stirring at 60°C for 5 hours at a stirring speed of 125 rpm to prepare a red wine-complex cyclodextrin complex;

[0036] (2) Red wine powdering: the red wine-cyclodextrin compound prepared in step (1) is spray-dried to obtain powdered red wine (moisture content 3.5%); the spray-drying conditions are feed temperature 55°C, homogeneous Pressure 40MPa, air inlet temperature 160°C, air outlet temperature 90°C, spray pressure 140kPa;

[0037] The powdered red wine prepared through the above steps is dissolved in water, wherein the mass ratio of the powdered red wine to water is 1:5 to obtain liquid red wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com