Yttrium aluminum garnet laser crystal doped growth device, crystal growth furnace and preparation method thereof

A technology of yttrium aluminum garnet and crystal growth furnace, which is applied in crystal growth, single crystal growth, single crystal growth, etc. It can solve the problems of long growth cycle and high production cost, save energy consumption, improve service life and prevent oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

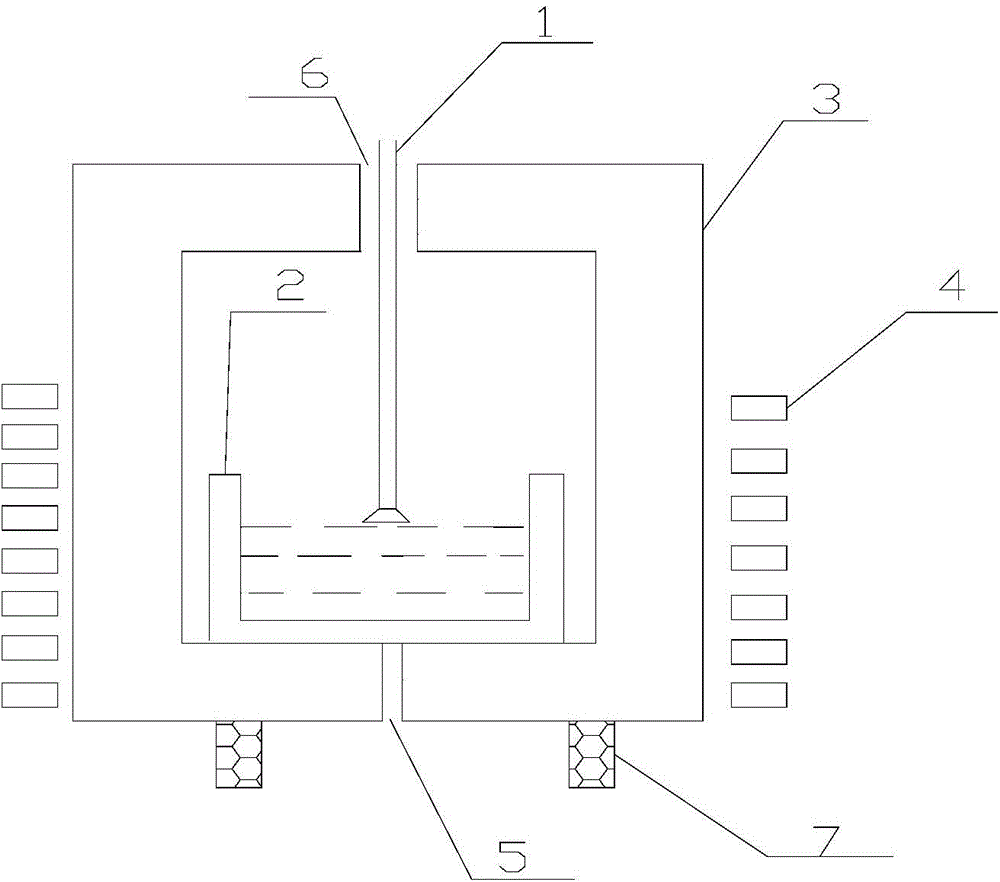

[0152] An embodiment of the present invention provides a growth device for doped yttrium aluminum garnet crystal, with figure 1 Schematic diagram of the structure of the device. as attached figure 1 As shown, the device includes: a crucible 2, an insulating tube 3 arranged outside the crucible 2, a copper induction heating coil 4 arranged outside the insulating tube 3, and a seed extending into the inside of the crucible 2 through the insulating tube 3. crystal rod 1;

[0153] The bottom of the heat preservation cylinder 3 is provided with a through hole 5, which is used to feed nitrogen into the bottom of the crucible 2; the middle position of the top of the heat preservation cylinder 3 is provided with a first round hole 6 for passing through the seed rod 1 , the diameter of the first circular hole 6 is 140mm. Wherein, the crucible 2 is a tungsten crucible, and the insulation cylinder 3 is made of carbon-doped boron nitride ceramics.

[0154] During the use of the crucib...

Embodiment 2

[0156] An embodiment of the present invention provides a growth device for doped yttrium aluminum garnet crystal, and the growth device has the same structure as the growth device provided in embodiment 1. The difference between the two is that in the device provided in this embodiment, the crucible 2 is a molybdenum crucible, and the diameter of the first circular hole 6 is 90 mm.

Embodiment 3

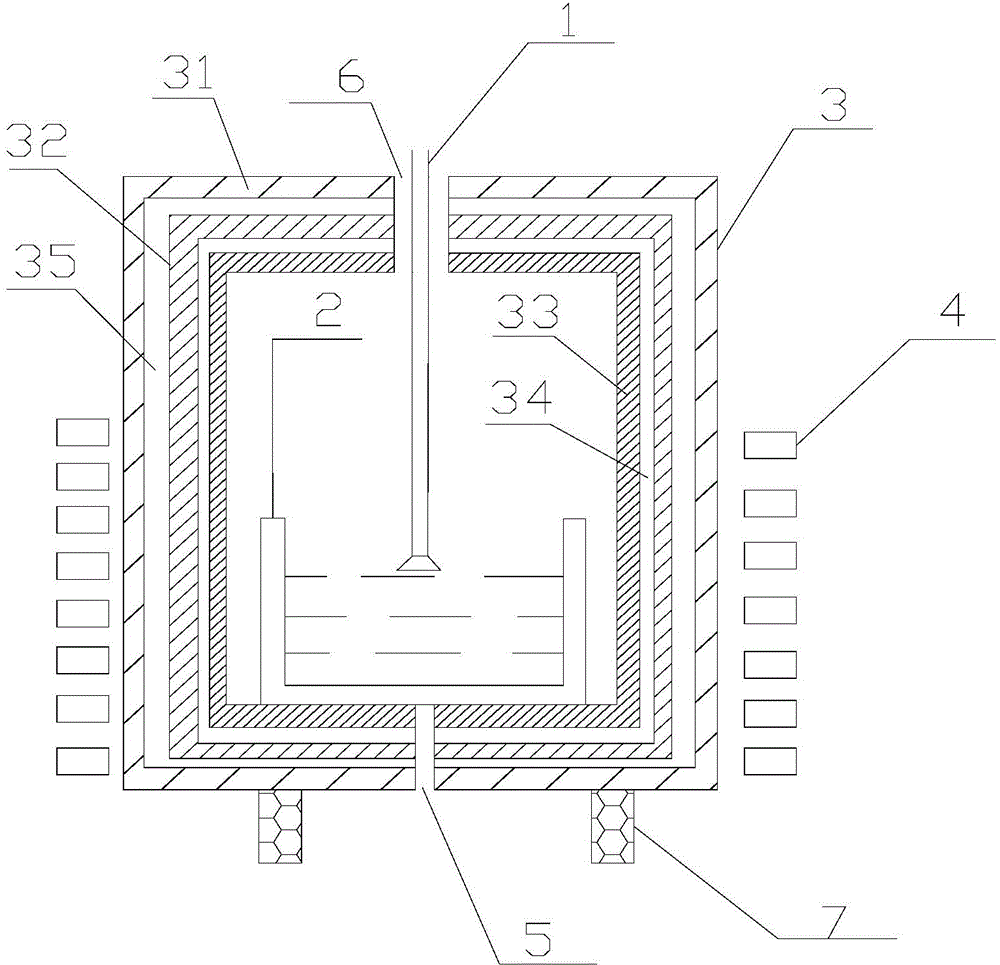

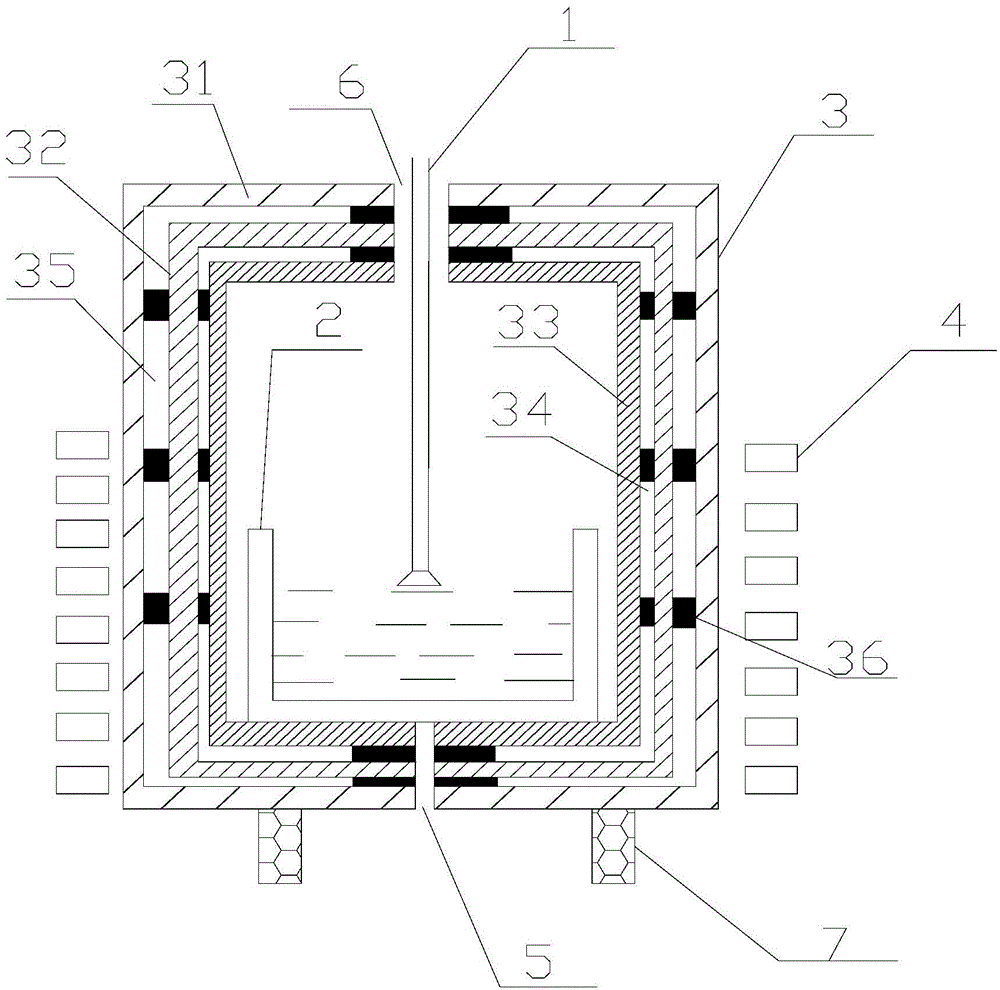

[0158] An embodiment of the present invention provides a growth device for doped yttrium aluminum garnet crystal, with figure 2 Schematic diagram of the structure of the device. as attached figure 2 As shown, the device includes: a crucible 2, an insulating tube 3 arranged outside the crucible 2, a copper induction heating coil 4 arranged outside the insulating tube 3, and a seed extending into the inside of the crucible 2 through the insulating tube 3. crystal rod 1;

[0159] The bottom of the insulation tube 3 is provided with a through hole 5, which is used to feed nitrogen into the bottom of the crucible 2; the middle position of the top of the insulation tube 3 is provided with a first round hole 6 for passing through the seed rod 1, The diameter of the first circular hole 6 is 140mm.

[0160] The thermal insulation cylinder 3 comprises an inner thermal insulation cylinder 31, a middle thermal insulation cylinder 32 and an outer thermal insulation cylinder 33 connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com